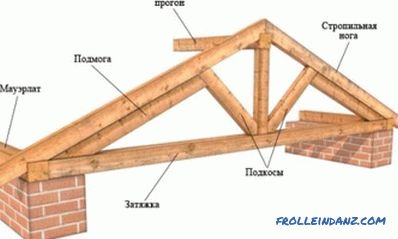

At the beginning of the mansard roof planning, a system of rafters is selected, which serves as a supporting structure. The type of roof system required is determined based on the type of roof.

Design of the truss system.

Depending on the chosen system, it can be wooden bars used as a roofing frame that holds the composite building materials of the whole structure, or concrete elements that create supports, called truss feet. Before starting work, wooden components are impregnated with special compounds that protect the roof from fire and rotting. The quality of this procedure directly affects the durability of the roof.

Varieties of truss systems and their device assemblies

The truss system is divided into two main types: slant and hanging rafters. Since the nodes of the connection in each of the systems have different characteristics, a certain type of rafters is selected based on the properties of the preferred roof, including its architectural features.

The main factors when choosing the right type of system:

Types of fasteners for rafters.

- the overall functionality of the roof;

- the pressure force of roofing materials on the structure;

- the prevalence and frequency of precipitation in the area where the house is located.

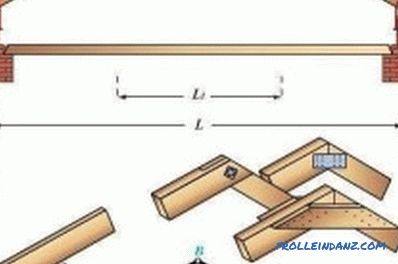

In the hanging type of rafters there are no supports that are located in the gaps. For this reason, there is a reinforced thrust, transmitted horizontally to the walls of the building. To reduce this figure, in the node supports introduce a protracted element of wood or metal, designed to combine the rafter legs. Thus, the hanging trusses take the form of a triangle. The tightening element is placed at the base of the legs, it performs the function of the crossbar (most often used in gable roof structures) and works for bending and compression. From the height of the draw element depends on the strength of the connection with the base of the supports.

Diagram of the device and attachment of hanging rafters for the roof roof.

The outboard type of rafters is often settled in buildings where there is a central support column or a supporting wall. The rafters rest their limbs on the sides of the building, and the central part rests on a column or other support inside the house. Such a construction site is designed for bending operation. Suspended supports create less stress on the components of the building, so their installation is not as time consuming as in the case of hanging rafters. In addition, it does not require large material costs.

There are also roof arrangement options that combine both types of rafters. In this case, each type alternates, that is, zones without load-bearing walls are equipped with hanging rafters, and areas with the necessary supports - nasal.

Competent arrangement of the truss system

The main factor in the high strength of the roof in a future building is the competent arrangement of all the nodes and anchor points.

In the case of suspended rafters for a mansard roof, it is assumed that there are at least 3 strong points. This value may change if the span exceeds standard values. For example, if the span is not more than 10 m, only one additional support is required.

The suspension support assembly is assembled based on the dimensions of the span. On small spans, the lingering element is most often replaced by a bolt. With a large span, the protracted elements sag, and the supports go to a bend.

Thus, the nodes of the hanging type can have the following differences with respect to the size of the span:

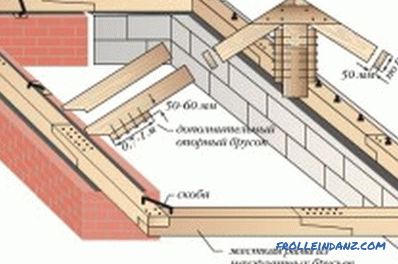

Figure 1. Diagram of the Maurate device.

- 9 m. Supports should be held back with a wooden bar, which is installed perpendicular to the attic floor. In the area of the base it is fastened with brackets, and the protracted elements are fixed with special clamps.

- 13 m. Fasteners are made with the help of struts, which abut the top against the base, and the lower part - into the perpendicular beam. The interval between the supports should not be more than 5.5 m.

- 17 m. The base must be reinforced with special tools. To the top, a trussed structure is used: the lingering elements are attached to two wooden bars, and a bolt is mounted between them.

Methods of fastening nodes

Regardless of whether replacement of the existing truss system or its erection from scratch is required, it is necessary to follow a certain set of rules when attaching its nodes.

First of all, you should avoid the simplest fastener of the crossbar and the base of the support, as this can have a destructive effect on the entire roofing system.

Figure 2. Attaching a truss foot to a power plate.

In other words, from the load created by building materials or precipitation, the ends of the supports slide off and the roof system is damaged. This leads to its complete collapse. To prevent such an outcome, it is necessary to increase the reliability of these nodes. This is achieved using the following types of fastening:

- teeth in the spike;

- teeth in the stop;

- emphasis on the end of the crossbar.

Depending on the grade, you can use one or two teeth. To increase the reliability of the connection, you can create additional fasteners with metal corners.

Knots of fastening of the roofing lathing

The main knots of fastening of the rafter system are:

Beam attachment

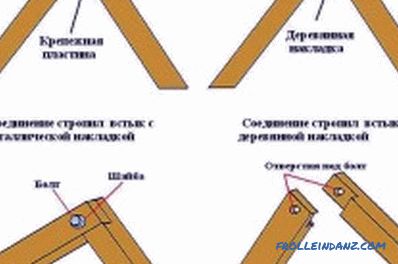

Figure 3. The ridge connection scheme of the truss system.

In the rafter leg, teeth are created in the spike, and in the crossbar a slot is cut, which corresponds to the cut teeth. In this case, the nest should occupy no more than 30% of the entire thickness of the crossbar.

If lightweight materials were used in the construction of the roof, and its slope is less than 35 °, the bases of the supports are placed so that the area of their anvil is much larger than the beam. This can be achieved by applying a frame with two teeth in 2 spikes, an abutment (with or without a spike), and also two spikes in the lock.

The nodes of the system are fastened either with hardware with metal corners, or wood sticks, plates and spikes.

Mower assembly attachment

There are 2 technologies for hardware mounting of supports: rigid and sliding (Fig. 1).

In the first case, a strong connection is established between the rafter and the power plate without the possibility of sliding, sagging, and jumping out. This is achieved by placing special angles with a support bar. Formed knot must be secured with reliable wire with the help of hardware. Nails are hammered at a certain inclination on the side so that they are in a crossed state in the mauerlate. The last nail is nailed vertically. This method is the most popular.

In the second case, the fastening is carried out using a special mechanism that allows a certain element (in this case, the rafter) to move in the right direction (Figure 2).

To create such a connection, you will need to perform a sidebar on the supports, and then lay them on the power plate. As in the previous case, both parts of the assembly are fixed with the help of two crossed nails and one vertical from above. To the mauerlat boards are fastened with metal brackets. After that, the support base is released over the wall and sealed with plates and a sled. Thus, the emphasis is on the mauerlat, but all components of the truss system can move within acceptable limits.

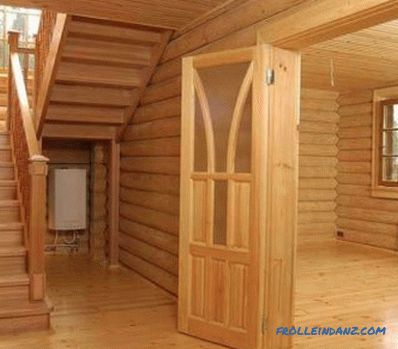

This method is most often used in the construction of the roofing system of wooden buildings (logs, log house), which are characterized by subsidence. It is worth remembering that with a rigid mount there is a possibility of damage to the walls of the building.

Ridge attachment

Such a knot can be created by two methods: butt and overlap (Fig. 3).

The first method implies a trimming of the top of the supports under the same slope as the angle of the roof. They are rested against opposite supports, which also need to be cut. The fastener is created with the help of two nails (150 mm), driven from above at a certain angle, so that they are located in proportion to each rafter. To improve reliability, the seams between the supports are fastened with wooden plates or metal plates.

The second method is the most popular. From the first method it is distinguished by the overlapping docking method. In this case, the supports are connected not by the ends, but by the side parts, after which they are fixed to the bolts.

Didn't find the answer in the article? More information on the topic:

-

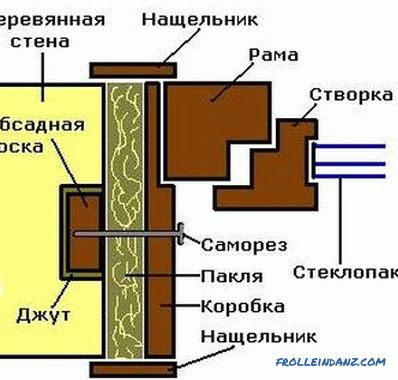

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.

-

Do-it-yourself wooden house

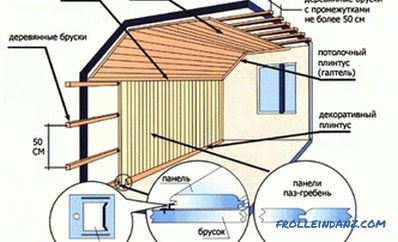

Finishing a wooden house: features of the work. What finishing materials are used to finish the wooden house from the inside, the technology of their installation.