Any building material over time begins to deteriorate, collapse and crack. Such characteristics can be attributed to wood. Old and worn floors, making unpleasant creaking sounds, are not able to decorate the room or please its owner. In this case, it is necessary to replace the previous coverage. To do this, often use plywood. How is the installation process? Laying plywood on wooden floor has distinctive features, which can be found in the information provided.

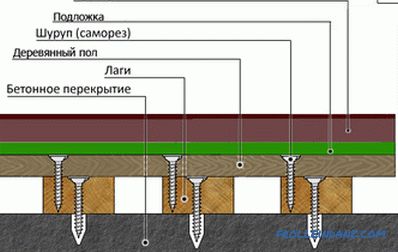

Laying plywood on wooden logs.

Methods for laying plywood

When choosing plywood for flooring, take into account the degree of wear of the base. In this regard, apply 2 ways of installation. The presence of the normal state of the initial coating indicates the laying of this material immediately on a wooden base. The presence of squeaking, bending and other defects on the surface indicates the replacement of the old coating.

Before installation, you should prepare for the work, namely, to test the surface for moisture. It helps to understand whether a given problem exists in a particular case. For this, the floor is covered with polyethylene film for 3 or more days. This time is given for observation. The lack of fluid for a set period gives grounds for carrying out repair work on the chosen scheme.

Features of mounting plywood on different bases

Laying plywood on a wooden floor.

The process of laying plywood is based on covering various types of surface. Each of these grounds has only its inherent features and characteristics. For this reason, it is important to find out what material underlies it. Wood, cement or lag talk about the use of various technologies in the installation.

Cement coating. Laying plywood on such a floor is associated with the use of special racks that monitor the flatness of the base and the horizontal plane. This floor has a special strength, it is able to withstand maximum loads. For this reason, the plywood coating is most appropriate.

Insertion on logs. This method refers to the most complex option concerning the installation and significant investment of funds. Here there are special nuances: lags are placed so that their parts at the top are on the same level. After that the floor is covered with plywood. In this case, the joint of one of the layers must fall strictly on the lags. Quite often, the space between the lags is used to the maximum, here you can arrange communications, a layer of insulation, material for absorbing sounds.

The plywood floor has not only advantages, but also shortcomings. When it is laid, the ceiling height is significantly reduced. It can be reduced by 9 cm, which is noticeable even visually.

Tools for plywood laying.

Wood floor. Any coverage over time becomes unusable. The wooden floor can be restored with the help of plywood on it. This method is classified as affordable, effective, and reliable.

Laying plywood on a wooden floor is nothing complicated and new. Even an inexperienced master can handle the work of this plan. This method is often used as a leveling start.

Required materials and accessories for installation

When installing plywood, you should know that the thickness of the formation in question is determined by the type of material chosen. Fastening on logs involves the use of material with a thickness of 15-18 mm. Basically the floor option is calculated on plywood, whose height can not be less than 12 mm. To work, you need to stock up with the necessary tools:

- construction level;

- screws and dowels;

- screwdrivers;

- electric jigsaw;

- roulette.

Uniqueness of installation work

There are 2 ways to lay plywood on the floor. Select will help determine the type of coating. One of these methods is associated with the fixation of layers on the base itself, the other consists of mounting on the laid logs.

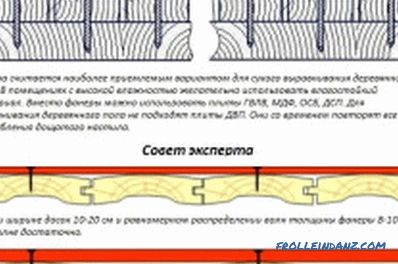

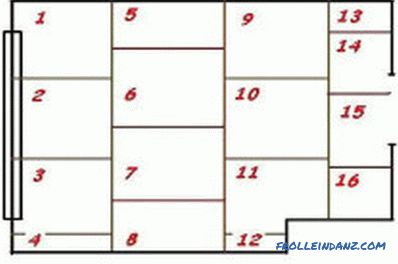

The procedure for putting plywood in a room.

Before giving preference to a particular method, it is necessary to critically evaluate the situation and make the right decision. If the surface is distinguished by perfect indicators: there are no drops, depressions and pits on it, installation work can be carried out directly on the surface. As a result, it becomes even smoother and smoother. The material will have first-class initial properties.

Placement on lags is used in the case when the floor surface has significant defects in the form of bumps, pits, and drops.

Installation work can be done either with nails or with screws.

The quality indicators of both options are equal.Well, if the work will be used large, whole layers of material. They will please their owners for many years. Their functionality will be preserved.

The main points of plywood laying, recommendations

On the eve of such work, it is necessary to check the strength of the old foundation. The deflected areas are subject to replacement.

To cover the floors with plywood, you should exclude rooms in which there is a high dampness or there are significant changes in temperature. So, in the pantry or bathroom, such coverage will not work.

Floor covering scheme with plywood.

The space between the wall and the plywood layers should correspond to a distance of 2 cm. This gap will be needed later. Ugly gap should be closed floor plinth.

It is very convenient if the available sheets are numbered, which significantly speeds up the work and gives it a light character.

While giving preference to one or another type of structure, one should pay attention to the thickness indices. A good example of plywood is a thickness of 1.5 cm.

On the eve of the installation work, the surface should be cleaned from dust and litter, after which the treatment with a ground mixture is required.

Any used fasteners must be 3 times thicker. Upon completion of the installation work, the laid elements are thoroughly polished on special equipment or regular emery paper.

When carrying out any work of a construction orientation, one should not forget about the basic thesis: performance of work will qualitatively noticeably prolong the service life. Getting started, do not forget about the main points and originality of the installation technology.

When purchasing plywood at retail outlets, it is important to focus on the brand of a particular manufacturer. So, the most safe option is FC material. It contains safe substances that do not cause toxic effects. Such varieties are often used in the design of children's rooms.

Plywood can be ground and without grinding, treated on one or both sides. Choosing this type of material, you can significantly save money by purchasing a product of low quality. Yes, and a beautiful, polished material is absolutely not needed flooring. For this, it is best to buy samples without grinding. They will cost much less.

When the floor plane does not have a strict horizontal position, then the furniture may be damaged. Cabinet doors begin to move to the sides, making it difficult to open and close. The legs at the table are deprived of an even and strong support, and the unevenly lying plinth begins to warp: one of the sides is lowered, the other, on the contrary, rises and protrudes to the sides. This picture is usually replaced by lagging. Lags are placed at a distance of 40 cm from another part. A large deviation of the base of the floor leads to the use of timber of different thickness.

After the completion of repair work, it is necessary to monitor the correctness of fasteners. To do this, take a small-sized bar, which knocks the floor surface. The presence of deaf sounds speaks of voids, they should be fixed with a long screw.

Didn't find the answer in the article? More information on the topic:

-

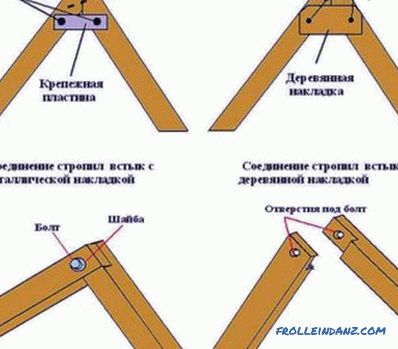

Types of mounting for rafters

Varieties of rafters. Rafters and plates for their fastening. Features truss-beams. Original truss mounts.