Parquet has many advantages, for which this material is used quite often as a finishing coating. Choosing this material, you bring into your house a piece of nature, because it is performed on the basis of natural wood.

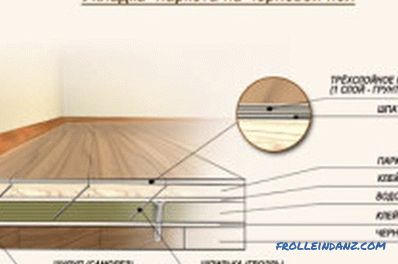

The device of the floorboard.

Instructions for laying parquet is not complicated, and its price is lower compared to parquet. The planks are connected at the expense of the locking system, which is built in the thorn-groove type, the material is processed in the factory, therefore the fit of the products to each other is as tight as possible.

Tools and materials for the installation of the floorboard by the floating method

Laying the parquet on the sub-floor.

- rubber bar;

- hammer;

- plastic film;

- adhesive tape;

- primer;

- scraper machine;

- PVA;

- self-tapping screws;

- parquet;

- cork backing.

Preparation before installation

The laying process must precede the preparation of the material, the floorboard must undergo acclimatization, for this it should be placed in a room, removed from the package and left for a day.

Laying should be done on an even basis, in addition, the wall surface should also be leveled, since the installation of products of the first row should be done parallel to the vertical base.

The parquet board can also be laid on a wooden surface, which, before starting work, should be analyzed for safety and suitability for further use as a rough substrate. So, the wood must be strong, not have traces of rot, some parts of the base should not create squeaks under mechanical action.

Stages for laying parquet.

If the boards have lost elasticity and formed gaps, they should be eliminated by filling the gap with white glue. If the floor is arranged on logs, then some boards could move away from them, in this case, reinforcement should be made with screws, then the surface should be rounded. Lags must also be checked for suitability. If some of them are exposed to mold and rot, it will be necessary to replace the frame.

The installation of the floorboard can be made on a concrete base, which should not have significant horizontal differences, such a surface has to be laid again. The mixture should be completely dry, only after that you can proceed to the work on laying the parquet.

You can find out if the screed is ready by covering it with plastic wrap for about a day. After the mentioned period has elapsed, no condensate should form on the inner surface of the film, otherwise the base is not yet ready for further work. The concrete base must be additionally coated with a primer.

Technology of laying floorboard

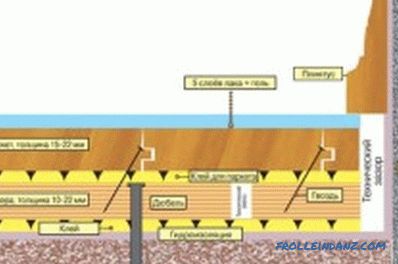

Fastening the parquet with nails.

Laying of parquet should be done under certain conditions that require compliance with the temperature regime, in particular. So, the room should not be below + 18 ° C, it is necessary to ensure that the humidity level should not exceed 65%. This will provide a better result after installation. The coating will be not only durable, but also resistant to all kinds of effects.

A parquet board whose thickness does not exceed 20 mm can be laid in 2 ways. More often than others, the so-called "floating" method is used. At the initial stage, it involves the removal of dust and dirt from the surface, in the process of which you should use a vacuum cleaner. Next, on the basis of the need to lay a plastic film, whose thickness is 200 microns.

Rolls of material should be laid out with an overlap of 15-20 cm, the same film should be on the wall. Sheets of film between them must be strengthened with scotch tape. Then to lay the cork backing, which must be laid butt. It is possible to replace the substrate with foamed polyethylene, but during its installation it is necessary to provide an overlap. The joints in the latter case, you must glue the metallized tape.

Layout of the floorboard.

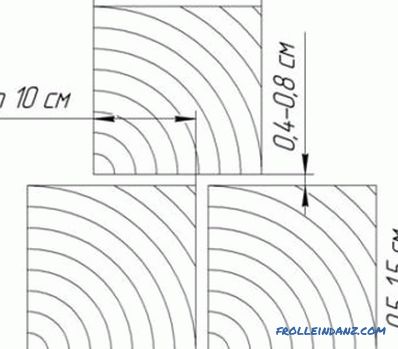

Before starting the installation of the initial row of parquet, it is necessary to calculate how many items you need to fill the entire width of the room. For this, it is necessary to measure the width of the latter and the width of one product, the first value should be divided by the second.

If you get a non-integer number, then one board will need to be adjusted in width. If it is necessary to reduce the width of the product by more than 5 cm, then the first and last row should be reduced to the same width. To do this, the required figure for trimming one board should be divided by 2, and it is by this number of centimeters that the boards will have to be cut to the width in the first and last rows.

The laying of the floorboard should be carried out perpendicular to the wall, which has a window opening. The first product should be wrapped with a spike against the wall, but it must be cut off beforehand.

The distance from the finish to the wall will be determined by the length of the room, for 1 m of the length of the room it is necessary to ensure a gap of 1.5 mm, but if the room has a length of 6 m, then the gap should be equal to 9 mm. These gaps will equip around the perimeter of the room. Fix the position between the board and the wall will allow the pegs. Durable connection of the boards among themselves can be achieved by striking a hammer on the attached rubber bar, which should be laid to the last board.

The laying of the 2nd row must be started from the board, the length of which should be 2/3 of the whole product, in the 3rd row the first board should have a length equal to 1/3 the length of the original products, the 4th row must begin to lay with a solid board. Installation of floorboard in the 5th row should begin as in the 2nd.

If there is a pipe on the way, then a round hole should be drilled in the board, the diameter of which should be 3 mm larger than that of the pipe.

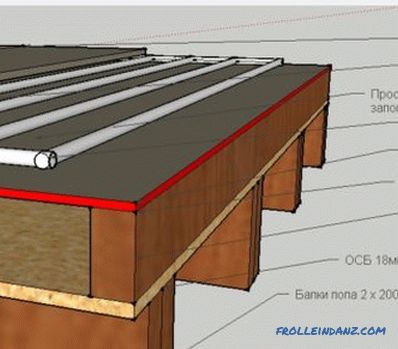

When laying the floorboard in the overall room should use an adhesive method. Initially, to implement such a method, sheets of moisture-resistant plywood will have to be laid on the surface of the subfloor, which must be reinforced with self-tapping screws.

The substrate should have a width of 18 mm. If ordinary sheets were purchased in the store, they should have a size of 1.52 x1.52 m, from each of them four equal pieces should turn out, between them it is necessary to form a gap of 5 mm. Plywood after installation should be primed and sanded.

After you can begin to lay the floorboard, the principle of the work remains the same as described above, but first apply parquet glue to the surface of the plywood.

Once the boards have been laid throughout the room, you can get rid of the pegs around the perimeter, and the gaps will need to be covered with plinths.

Care of the floorboard is simple enough, the surface should be vacuumed, and then wiped with a damp cloth. The board must be protected from moisture; if this happens, then water should be removed from the surface immediately.

In the walls of your home, any home craftsman can do the laying of the parquet, it is important only to learn the technology before starting.

Didn't find the answer in the article? More information on the topic:

-

Self-supporting wooden floor

Step by step instructions on how to do the screed on the wooden floor with their own hands. Necessary for work tools and materials. The main stages of the workflow. Calculation of the mixture for the room.

-

How to lay the plywood on the screed

Laying plywood on the screed: preparatory work, applying primer on the screed, laying waterproofing. Technology and installation features of plywood on glue. Tools for the work.