Plywood in modern construction and repair is used quite often, so painting plywood is a very topical issue. The peculiarity of this material is in the method of its production. For its manufacture thin sheets of veneer are glued together. Used adhesive composition determines the characteristics of the material, for example, its moisture resistance. Depending on the degree of resistance to moisture, the plywood can be plain, moisture resistant or laminated.

Painting helps to protect the plywood from rotting and moisture, as well as to extend its service life.

Preparing for painting

You can extend the life of the base by painting it. Before painting plywood, it is necessary to prepare its surface for applying the coloring composition. The purpose of the training is to achieve maximum smoothness and flatness of the surface.

Painting of plywood is performed in stages. First you need to sand it with sandpaper number 80. After that, the primer is applied on an acrylic basis and left to dry completely. On the dried primer putty putty for wood, made on the basis of acrylic, as well as primer. The leveling layer must also dry out completely. After drying, it is ground with sandpaper No. 80-120. The surface is primed again, dried and painted.

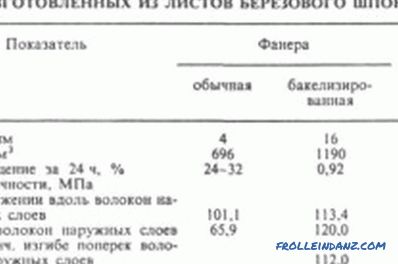

Plywood specifications.

The primer is used to protect the substrate against fungus. Apply the primer with a roller. You can not engage in alignment, if its relief does not put forward any special requirements. In this case, the material is primed and painted.

Grinding allows you to remove irregularities from the surface and prepare it for further processing. It is necessary to perform movements with emery perpendicular to the direction of the wood texture. If further processing involves the opening of varnish, then you need to perform and polishing along the wood fibers fine-grained sandpaper. The edges of the material can be slightly cut in the direction of the center. They are covered with 2-3 layers of acrylic paint.

Ground and putty the surface for the following purposes:

- leveling the surface capable of being absorbed;

- filling cracks on the inner surface of the veneer;

- extending material life;

- protection against damage.

How and how to paint plywood?

The choice of coloring composition and method of dyeing depends on the purpose of the material.

The main task of painting is to prevent cracking of the material. If the plywood will be laid on the floor in a room with high humidity, then it is necessary to cover it with paint on both sides, and the edges should be treated very carefully, they should be applied with several layers of the composition.

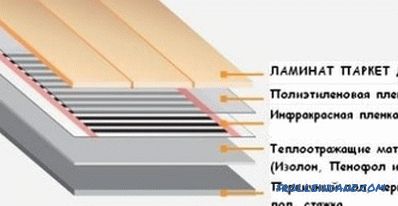

Plywood painting scheme.

How to paint plywood depends on the place of work. If it is a dwelling, then it is recommended to choose water-based formulations. Well in this case is suitable acrylic. On the prepared surface, it is applied easily and dries quickly, with almost no unpleasant smell.

If the material is to be used outdoors, the best option is pentaphthalic paint, which is a common enamel coating for wooden surfaces. The composition is applied easily and dries quickly.

You can purchase a ready-made composition, but if you like, you can stop at the basic version and tint the composition yourself. Before you paint plywood, you must make sure that it does not have excessive moisture. If the material was stored in conditions of high humidity, then it must be dried before processing to normal humidity.

To create an attractive glossy surface, plywood on the floor can be further varnished. This is not necessary if gloss paint is used. The paint on the surface of the material should be completely dry.

It is very important to decide in advance how to paint the plywood on the floor. The best option - sprayer. With it, you can achieve uniform coverage. You can use a roller, but only lint-free, and foam rubber. If necessary, paint a hard-to-reach area using a brush.

Thus, before painting plywood, it must be prepared for applying the coloring composition. Certain formulations are chosen to cover the substrate. Processing methods depend on the purpose of the material.

Didn't find the answer in the article? More information on the topic:

-

How to properly caulk a house from a log

Before you caulk a house from a log, you must decide on the material with which you make the insulation. Moss, tow, lnovatin, jute fiber, jute are used.