Independent installation of pipes for domestic heating is quite a complicated matter, but quite doable. The basis of the work is the welding of individual sections of the pipe into the whole heating system, the connection of radiators and the heating boiler. To weld metal pipes, you will have to use the services of a welder. This procedure promises unnecessary costs, as well as smoke and soot from welding in the apartment. Well, if you decide to do the installation of heating pipes with your own hands, use polypropylene pipes for work.

Distribution of the pipeline

Heating system

Heating system

The performance of the pipeline depends on the correct distribution of the pipeline your heating system. There are various schemes of heating systems, but there are two, the most popular:

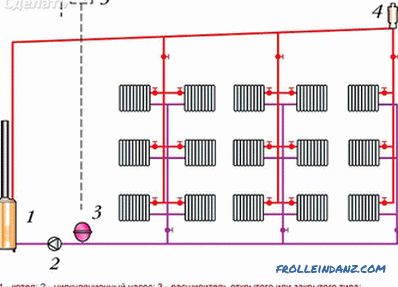

The system of the upper water spill is very beneficial for its independence from the forced circulation of water. The water heated in the boiler will rise through the pipe to the upper point and through the pipeline go down through the radiators to the lower (reverse) pipe. From the return pipe the water flows back into the boiler for heating. For the operation of this system, the pipeline is mounted on a level. It is necessary that from the exit of the boiler towards its entrance, throughout the pipeline there was a slight bias for the arbitrary circulation of water.

Top water spill system

Top water spill system

Such a system is advantageous in that it does not require the installation of a pump for circulating water . You save on electricity, and when it is turned off, the heating system continues to work. The disadvantage of the system lies only in its lack of aesthetics. The upper tube is used with a larger diameter than in the system with the lower spill. Such a pipeline is harder to hide in the wall. In addition, saving on electricity and the purchase of a pump, you will overpay for the increased consumption of energy used for the boiler.

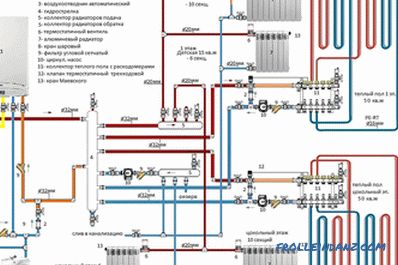

The bottom water spill system allows the use of plastic pipes of small diameter. Circulation of water in the pipeline will provide a pump. This type of system has a higher efficiency than that discussed above.

System of bottom water spill

System of bottom water spill

The advantages of installing the pipeline include laying a thin plastic pipe under the floor of the building and connection to her floor heating system. To the radiator from under the floor will come two small lengths of pipe for connection. The disadvantage of this system is its dependence on the pump. The electricity was disconnected or the pump broke - you cannot use the heating system.

Installation of the pipeline

Begin all work by planning the heating system. If you decide to install a heating system made of polypropylene pipes, practice soldering joints on unnecessary pieces of pipe. It will save you from unnecessary marriage at work. Based on the plan, get the required number of polypropylene pipes, fittings, taps, soldering iron.

- In the walls and ceilings of the building where the pipeline will pass, punch holes through the perforator.

- With scissors for cutting pipes, cut the required size of pieces, at the edges, remove a small chamfer, for a better entrance of the pipe to the fitting. On the reinforced pipe, clean the edge of the foil at a distance of the fitting depth. The reinforced pipe, covered with plastic on top, does not need to be stripped.

- Heat up the soldering iron and prepare for soldering. Calculate so that most of the soldering design to perform on the table. The wall should have the last soldering points to connect the entire structure. This method of installation will facilitate your work, and you will not be in an uncomfortable position with a soldering iron on the floor to solder each joint of the pipe.

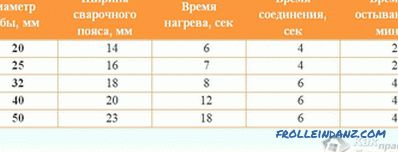

- Insert the edge of the pipe into the nozzle of the soldering iron on one side and at the same time the fitting on the other side. Warm up at a temperature of 260 ° C. Remove the blanks from the soldering iron and connect by inserting the pipe into the fitting. If you feel the emphasis of the fitting wall, do not put more pressure on the pipe. Otherwise, a squeezed edge may reduce the diameter of the passage. After a couple of seconds, the blanks are soldered. Soldering pipes of different diameters requires time, which can be found in this table:

Soldering time for pipes of different diameters

Soldering time for pipes of different diameters

- After soldering all possible sections on the table, lay the workpieces in their permanent place and fix the pipes in special holders. Then you have to solder all the weight of the workpiece in a single pipeline.

- In the next step, start connecting radiators to your system. It is advisable to install a ball valve at each radiator inlet and outlet. If one radiator fails, it will be possible to turn off the cranes with it, and the entire heating system will continue its work. When installing taps, tighten all threaded connections with a FUM tape. Screw the fitting into the valve from thread to plastic and solder to a common piping system. But this type of connection will be one-piece.To replace the radiator, you will have to cut the pipe, and then solder again. To avoid such a problem, install a detachable connection between the fitting and the tap - an American.

- Fully prepared heating system blow the compressor, directing the flow of air into the upper pipe - supply. The air must pass unhindered through the entire pipeline and radiators and go out into the lower pipe - the return pipe. If the air does not pass, it means that during the soldering process you made a marriage and soldered the passage through the pipe. There is nothing you can do, it is necessary to cut the pipeline in places and look for defective soldering.

- After a successful test, connect the pipes to the pump and the heating boiler. Keep in mind that the boiler must be located at the lowest point of the entire piping system and in a separate room. Connecting do all the same fittings with the transition thread on the plastic.

- Pump water into the system, bleed air from the radiators and check all connections.

Piping is done

Piping is done

After that, your heating system is ready for operation, you can turn on pump and ignite the boiler. And polypropylene pipes will give you a guarantee of high-quality system operation for at least 50 years.

Video

In this video, the specialist will share his knowledge and tell you how to do home installation of the heating system: