The steam room is just that building in a country house where the presence of the most natural materials is required. This requirement is justified not only by decorative considerations, but also by environmental ones. The release of steam and high temperatures are capable of greatly influencing the materials on which the wall, floor and ceiling are faced. And if materials are not of sufficient quality, they will emit harmful substances. Which tree is better to trim a steam room?

Figure 1. Diagram of cladding of the steam room with clapboard.

The main and best material for finishing the steam room is wood.

It is convenient to install and easy to maintain. The tree will influence only positively on the health of visitors. But there are quite a lot of tree species, so you should decide what kind of wood to use to finish Consider the most common and practical wood species designed for this purpose.

Overview of wood types for finishing the steam room

From wood today, two such basic materials as block house and wall paneling are used for finishing baths. But even they come from different tree species that have different properties. The best breeds for the bath are linden, larch, aspen, ash, oak, white locust, spruce, pine and cedar.

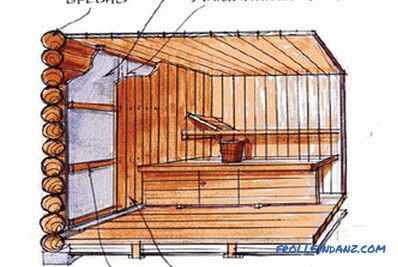

Figure 2. Wiring diagram of the block house.

Many wood experts constantly argue with each other as to which species to choose: deciduous or coniferous. On the one hand, conifers are good because they do not change their color over time, so they always remain in the form in which they were originally during installation. Hardwoods, on the other hand, are considered more resistant to temperature fluctuations and a high degree of humidity. But those and others have their own characteristics.

Hardwood trees

The linden is considered to be the best deciduous tree for decoration. This tree at the same time perfectly retains heat, but also does not heat up too much, due to which there is no burning of the skin, if you have to touch even the very hot walls. Lipa tends to produce twice as much essential oil as other trees. Therefore, it is ideal for the body. And due to the fact that her couples increase sweating and are hypoallergenic, the effect is enhanced.

Aspen is an excellent alternative to linden. According to its healing properties, it is the same. Moreover, this tree also has the ability to change the mood for a positive and calm. Aspen is not subject to rotting, and in work it is very easy due to the fact that its fibers are quite soft and docile.

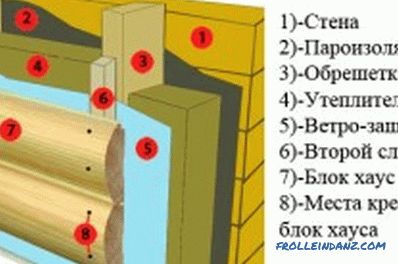

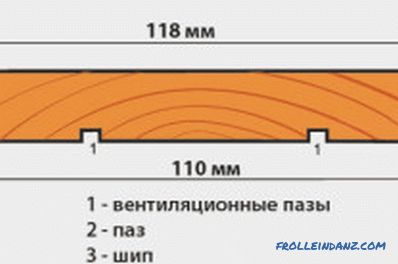

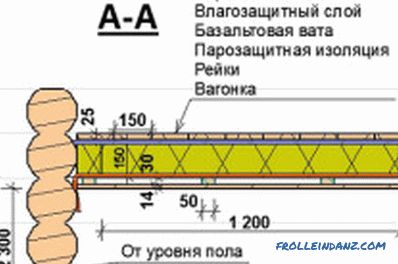

Layout of the device and dimensions of the wall panel.

Ash and oak have approximately the same properties. These are fairly durable trees, which are slightly affected by rotting and deformation under the action of high temperature, especially oak. They emit less antiseptic into the air, but are good enough in practical terms. Oak changes its shade to a darker one over time, but this does not spoil its appearance at all.

If you want a steam room that is as practical and useful as possible, then it is better to decorate some elements that are most exposed to heat from oak or ash. After all, ash and oak, despite the fact that they are resistant, tend to be very hot. Remember that ash must be treated with special means more carefully, as the risk of fungus is slightly higher.

Another excellent wood for finishing the steam room is white acacia. In the case of its proper pre-treatment, the acacia can surpass the oak in its strength and resistance to deformation. Due to the fact that the boards of acacia are less common, it is advisable to trim the floor of the bath, as it is exposed to more impacts.

Coniferous trees

Diagram of the ceiling trim of the steam room.

Of coniferous trees, it is advisable to dwell separately on larch. This is the most durable and sustainable conifer for the bath. It emits into the air a lot of useful oils that can greatly enhance human immunity. And if you make not only walls, but also floors, you can be sure that every year they will only become stronger. Consider the fact that such a tree does not attract bark beetles, which is another positive point.

Cedar has approximately the same properties. It costs a bit more expensive, therefore, if you do not have the ability to trim a steam room with it completely, you can use its wood for installation only in some separate parts. It is especially good to arrange cedar boards where the largest amount of steam accumulates. So increases its usefulness and antiseptic effect on the body.

Spruce and pine are also common tree species for finishing the steam room in the house. They are less likely to release beneficial substances into the air, more susceptible to deformation.But at the same time they are several times cheaper, and if you correctly process them before installation, they will last for a long time.

Finishing with clapboard, block-house and ordinary boards

Wall and floor paneling scheme of the steam room.

Now let's figure out what is better to sheathe a steam room: with an ordinary board, a block house or a clapboard. So that you can decide what to choose better and cheaper, consider some of the features of these three finishing materials.

The cladding of the steam room clapboard (Fig. 1). This is a good material, as it is easy and pleasant to work with it. Due to the fact that there are already places on the lining sheets for joints, they will fit well without inconvenience. Small gaps provide minimal circulation of clean air, which is necessary for greater durability of the material and prevent its deformation in the future.

There is no need to choose a paneling for finishing a steam room made of pine or spruce, as it will constantly emit a lot of resin, which will clog between the gaps and prevent air from circulating freely. The best type of wood is linden or aspen. Even if the air in the gaps may not be enough, the lining will not be deformed, these rocks are resistant to all influences.

The second finished material for finishing the steam room is a block house (Fig. 2). This is the most modern material, which according to its characteristics is capable of several times exceeding a very thick log. Due to the fact that the elements of the material are not flat, but slightly rounded, the tree will not be deformed, even if produced from wood of inexpensive varieties.

Another feature is the reduction with time of discharge of resin from block houses, which are made of pine or spruce. At the same time, wood does not lose its beneficial properties at all. The technology provides over time only an improvement in the quality of the breed of these trees.

But with strong heating, even such a finishing material becomes hot enough if it is made of pine (spruce). Therefore, to get involved in and trim the steam room in this way is not fully recommended. In general, a block house is good from any tree - both hardwood and coniferous.

Perhaps the most economical option would be to trim the steam room with ordinary wooden planks. This is cheap, since you can find and cut this type of board yourself, practically without spending money. Especially carefully you need to treat the process of treatment with antiseptics.

But finishing the steam room with this method has one significant disadvantage: it is quite difficult to make it yourself, since you will have to use screws, frame, to follow the joints. Therefore, there is no guarantee that such coverage will be ideal and will serve for a very long time. This finish is good for a temporary steam room, where large expenses are not provided.

So, when choosing a plating material and a method for plating a steam room, it is necessary to take all this into account so that the result of the work does not disappoint. This is especially true of the capital finishes of the steam rooms, where considerable funds have been invested.