There is no person who has not had to face the renovation of the house. Particularly acute problem of reconstruction of the premises is in the old buildings, where a simple tint and glue can not do. It is necessary to change both windows, and doors, and even floors. Overhaul is expensive, so many homeowners have to do it themselves to save money.

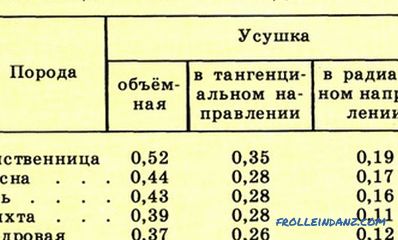

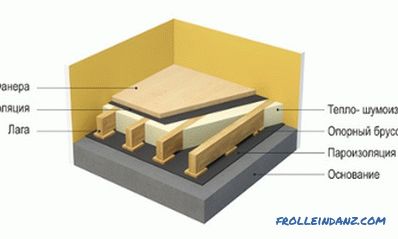

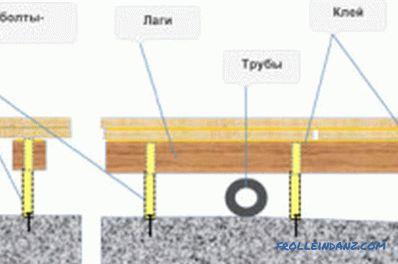

Scheme of plywood floor with lags.

For those who decide to renew the flooring themselves, it will be interesting to learn how to put plywood on the floor. Talking about plywood will go because the material perfectly replaces wood, as it is environmentally friendly, easy to process, and its surface conveys the texture of wood, and plywood retains heat well.

At the same time, it is cheaper, stronger than wood and is an excellent leveling agent for surfaces. Almost any finishing covering can be put on the plywood base, including ceramic tile.

Preparation for laying the lag

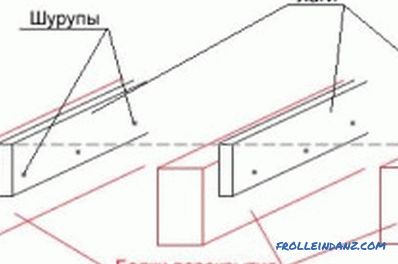

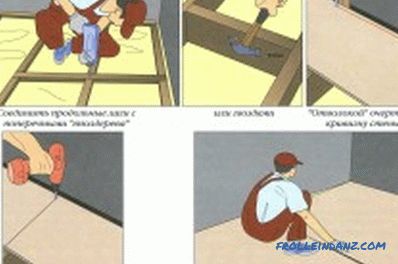

Layout installation scheme.

For arranging plywood floor through logs, you need to purchase the following materials and tools:

- bars with a cross section of 50 x 100 or 50 x 50 mm for a lag;

- plywood;

- heat insulator;

- hydraulic insulator;

- self-tapping screws;

- anchors with 10 mm cross section;

- jigsaw;

- level;

- screwdriver;

- drill or hammer drill;

- keys for anchor bolts;

- glue;

- primer, antiseptic

Upgrading the screed

If the plywood is not in contact with the base, it is still necessary to prepare it. Lags will rely on the overlap, so it must be durable, smooth and protected from moisture from below.

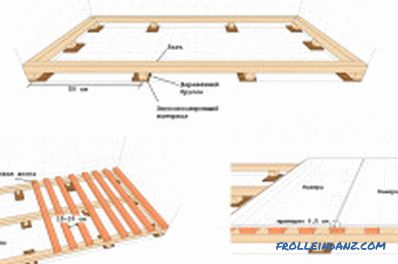

The scheme of the plywood base of the floor on the logs.

The first task is to clean the surface of the old screed and clean its fragments, dust and debris. After that, on the basis of the need to remove all cracks, potholes and bumps. The protrusions are removed, for example, by a perforator, and the grooves and cracks are sealed with a cement-sand mortar.

After solidification of the solution, the base is treated with antifungal composition and primed. It is worth noting that it is often necessary to level the overlap with a new coupler, since its condition does not allow a new floor to be qualitatively laid.

Please note that the leveling screed is placed on the surface that has undergone preparatory treatment. In addition, a waterproofing membrane made of polyethylene or bituminous materials must be laid under the screed. Before you put plywood and logs, the screed should harden. This process lasts 4 weeks.

Preparation of plywood and bars

In order not to lose time, you can start preparing bars and plywood for further work. Even in the store you have to pick the best quality blanks. Multi-layered veneer must be of high quality so that there are no defects on its front side and the plates themselves are not stratified.

When choosing bars, you should pay attention to the lack of curvature, besides you should not buy short bars. It is not recommended to extend logs, as extended bars reduce the strength characteristics of the floor. Their elongation is allowed if the room is too spacious.

At the same time, the joints of elongated lags in adjacent rows should not coincide with each other. Their spacing should be at least 1/2 m. It is necessary to add that the place of pairing of the bars must have a fulcrum. Before laying, the bars should be further dried for 10-14 days, and the wood should be protected from direct sunlight.

Stages for laying the floor.

Given all this, purchase blanks for lags with some margin. Circumstances may be such that you will have to reject some of the wood, and additional time will be required to dry the new bars. After drying, the logs are treated with antiseptic compounds.

Returning to the plywood, it should be noted that the flooring of the lag is done with a material no thinner than 15 mm. The frequency with which the support bars will be laid depends on the thickness of the plates. When purchasing materials, keep in mind that:

- for plywood 15-18 mm thick, the lag increment will be 400 mm;

- 20 mm - 500 mm;

- 22 mm - 600 mm.

Also, when choosing plywood, buy material for indoor use. Best of all, these requirements are met by the FK brand. Although it is less moisture resistant than FSF, but it is more environmentally friendly. To improve the performance of plywood in terms of resistance to moisture, it is enough to soak it several times with hot drying oil.

This is what you can do while the screed solidifies. Drying oil is applied to the plates until it is no longer absorbed into the veneer. The maximum saturation of plywood with impregnation can be determined by the drops that will remain on its surface.And before that, the impregnation heated to 60 ° C in a water bath is applied to the surface and rubbed with a brush.

The veneer is dried with a building dryer or a hot iron. The operation is performed on both sides of the panel. Immediately you need to warn that after trimming the edges of the plywood will have to soak again.

Laying the batten

The screed has dried, you can begin laying the bars. On the screed will have to lay another layer of waterproofing, the neighboring tapes of which must be placed on each other not less than 15 cm. After that, bars are put on the perimeter of the room. Their installation is carried out using the construction level. Even better, a horizontal line will be applied to the walls, defining the plane of the batten.

You can mark the walls with a water level and a paint cord smeared with chalk. If you made sure in advance that the plane of the leveling screed was perfectly horizontal, then the logs can be laid directly on its surface. There should be a gap of 3 cm between the logs and the walls.

The plywood floor should be laid on the logs.

Bars can be fixed to the floor in several ways. One of them is to push the anchors into the base through the body lag. For this purpose, holes are made in the bars, and through them drilling points are indicated in the screed. Anchor screws can be located 1 meter apart, and the screws are screwed into the dowels in 1/2 m steps.

Lags can be laid on supports made of wood or plywood, but pieces should be laid between the supports and the bars ruberoid. The supporting elements are attached to the floor with anchors, and the logs are screwed to them with self-tapping screws. In addition, as a fastening element, you can use steel corners, which are attached to the floor with dowel-nails, and to the logs - fasteners for wood. It should be noted that the anchor screws provide the strongest connection of the batten with a coupler.

After fixing the bars along the perimeter, transverse lags are laid. Before laying them stretch horizontal threads between the opposite walls, then the bars will be easier to orient horizontally. When laying the crate on the threads, still check the installation level. Tackle logs screws. Metal corners can also be used to connect them.

Crate on the ground

Installation of plywood floor on logs.

Sometimes it is necessary to lay the lags not on the coupler, but on the ground. There is nothing wrong with that. Its top layer is removed, and the remaining soil is thoroughly compacted, after which a layer of crushed stone is poured in 5 cm.

After leveling the bedding, the hydroinsulator is laid. First, the bars are attached along the walls, and then the rest. The bricks are supported by the lags, but between them and the beams there must be strips of wood not less than 2.5 cm thick. Otherwise, the device of the batten on the ground does not differ from its mounting on the screed.

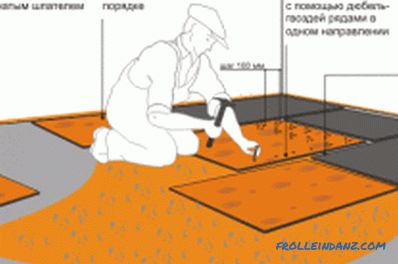

Flooring plywood

Before you put the plywood on the floor, you need to lay thermal insulation in the crate. As it can be expanded clay, mineral wool or polystyrene foam. After that, you can proceed to the flooring of plywood.

Cut the sheets of material so that the joints of the adjacent plates fall on the center of the bars. In addition, stacking veneer sheets in staggered order will add extra strength to the flooring. If possible, arrange the joints of the plates in those places where the walk will be least likely.

The surface of sheets and bars in places of contact with each other is better treated with glue. The plywood with beams is made by self-tapping screws, but before they are screwed in, it is necessary to drill holes in the slab. The fastener pitch should be from 15 to 30 cm.

Self-tapping screws, which are screwed at the adjacent edges of multi-layer veneer, should not be facing each other.

Position them with a half-step offset.

Maintain compensation gaps (up to 0.5 mm) between adjacent panels. Between plywood and the wall also need to leave a gap of 2 mm. The same distance is maintained between the plates, if the plywood will serve as the basis for the finishing coating. The gaps between the sheets are sealed with elastic mastics. Laying of plywood in several layers is allowed. In this case, the joints at different levels of the floor should not coincide with each other.