0 Now it is rare to find that the house under construction was without a warmed foundation. How can you make the foundation warming with your own hands, and what is the reason for the need to perform such work?

The fact is that sudden changes in temperature and heavy rains do not affect the foundation in the best way, and over time it begins to collapse. The conclusion suggests itself - you need to warm the foundation! However, other questions immediately arise:

- Can sand act as a heater?

- How to insulate with expanded clay?

- How to insulate with expanded polystyrene?

- How can we insulate slab base?

- How to insulate a columnar foundation?

- How to insulate a pile foundation?

- Which insulation should be used?

Answer all questions in order.

Sand

Perlite sand

Perlite sand

Although ordinary sand is not a heater, everything - So it can be temporarily used for these purposes. Such insulation is inexpensive, and often this method insulates the foundation of baths before the walls are erected. This "insulation" must be reliably protected from moisture ingress into it.

It is more efficient to use perlite sand, which can act as a heater, and therefore more efficient. Working with any of these materials will have to deal with the implementation of a large amount of work, and have a lot of sand, because the height of the backfill must be brought to the level of the floor.

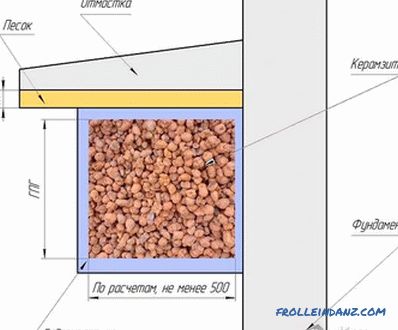

Expanded clay

Expanded clay backfilling - scheme

Expanded clay backfilling - scheme

This material is widely used in Russia as a heater. This was influenced by its good thermal insulation qualities and low cost. When pouring the foundation, claydite is placed in its inner part, however this technology has its drawbacks.

Basement insulation with expanded clay

Basement insulation with expanded clay

The excellent qualities of expanded clay, as a heat insulator, are significantly reduced by the surrounding concrete, as is known, is a real conductor of temperatures. This method is used for shallow basement.

Due to the low weight of this composition, it is possible to safely formwork from slate.

Expanded polystyrene

Expanded polystyrene insulation

Expanded polystyrene insulation

This insulation is made in the form of sheets, thanks to what process of warming is much simpler. However, before starting work, it is necessary to apply waterproofing of the foundation at the points of contact with the insulation. Sheets are attached from the bottom of the foundation to the floor level. The thickness of the material may vary depending on the type, thickness and depth of the foundation. Since the expanded polystyrene is destroyed by sunlight, the visible part of the insulation should be immediately closed with facing panels.

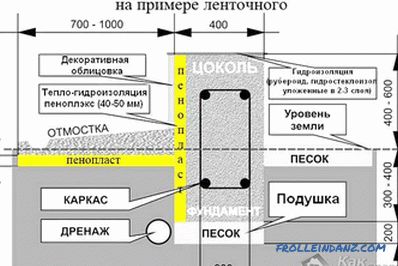

Foam insulation technology

Foam insulation technology

Works are not difficult, but they need to be done correctly. First, a waterproofing membrane is fixed on the foundation, and then polystyrene foam is stuck onto it with the help of special glue. The consumption of glue is small, as it is applied to the plate point.

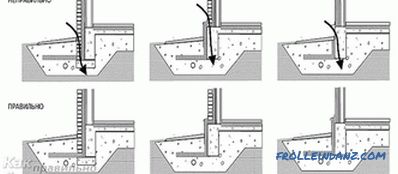

Wiring Error Scheme

Wiring Error Scheme

Another membrane is also placed to remove groundwater, which also serves as protection of the thermal insulation material.

Warming of the slab foundation

Previously, only foam plastic was used for this purpose, but due to the short service life (binding properties are lost, and foam crumbles into balls of which it consists), it practically ceased to be used. Today extruded polystyrene foam is used everywhere, which has a high density, and it can be used for decades.

The following is the order in which the layers of this “cake” are laid: plastic film spreads, and then the plate is poured. Thanks to this design, moisture and cold from the soil do not enter the room.

- Geotextiles are laid at the bottom of the excavated pit.

- Pour a layer of sand and rubble.

- Then, just before laying the plate, insulation is laid.

- A reinforcing structure is manufactured on it.

- Pouring concrete.

As you can see, nothing complicated.

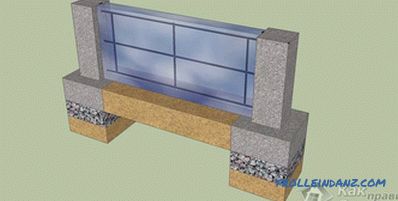

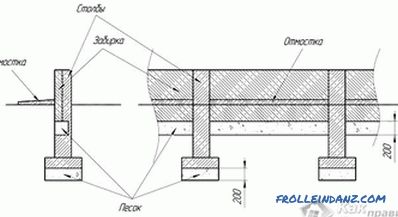

Warming of the columnar foundation

Slip

Slip

If under the designed building, which will be stand on heaving soils, the basement is not planned, it is possible to make a column foundation, but its insulation has its own nuances. Most often for these purposes special zabirki are made, which play the role of a socle.

Zabrka columnar foundation

Zabrka columnar foundation

These are low walls, for the manufacture of which are used wood, less brick or a rock. Expanded clay is poured into them, which will well protect the foundation pillars from freezing, so they will not suffer even with a strong swelling of the soil.

Warming pile foundation

The pile-screw foundation is completely submerged to a sufficiently large depth in the ground, therefore it only requires external insulation of the grillage, which must be isolated from moisture because in contact with reinforced concrete it will lead to corrosion. You can use various insulating materials.

What is better to use?

Extruded polystyrene foam

Extruded polystyrene foam

Choose a good insulation is already half the battle. Today, a "sea" of heaters is offered, and each manufacturer tries to convince the buyer that his product is the best, but we will approach the selection in the right way, assessing the insulation according to its characteristics. Probably no one would argue that a suitable material should not:

- deform from the soil pressing on it;

- absorb water.

By applying all these two requirements to the purchased material, you can warm the foundation with your own hands, without fear that the insulation will not bring results.

In this article, we especially note only polystyrene foam, which today is the most popular insulating material. It is valued for the fact that it is convenient to work with it: it can be cut exactly, and then glued or fastened with screws. Unlike foam plastic, it does not crumble, does not absorb water, which means that with the onset of frost, frozen water will not destroy it. He also does not let air through. Thanks to such excellent properties, polystyrene foam will last a long time without losing its insulating qualities.