The construction of almost any wooden object is associated with a large number of problems. After all, wood is a natural and very plastic material, demanding to external conditions. It is devoured by fungi and pests, the tree rots and changes its characteristics. The manufacture of products from raw material leads to the subsequent distortion, cracking of the base due to drying out. And the tree is reduced in different ways, depending on the parties.

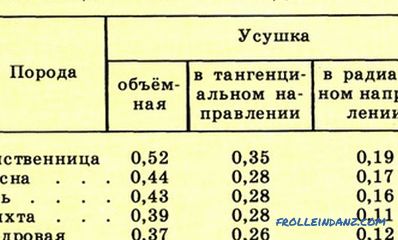

Wood shrinkage rates.

Drying of wood is one of the most common problems that are familiar to anyone who has worked with this material. During construction work, allowances must be made on a natural basis, in which case the shrinkage process will be painless, and the appearance of the building will remain unchanged.

Definition of the concept, features

The drying of wood is understood as a reduction in the size of a linear nature and volume values over time. It can be observed at the moment when the moisture leaves this material. The phenomenon of such a plan is characteristic of all tree species, and some of them are more influenced than others.

Shrinkage accompanies any of the drying processes of natural breeds. From their fibers comes bundled and adsorbed water.

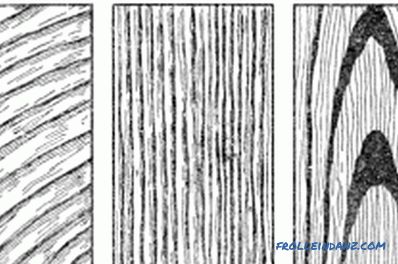

Shrinking and warping of faces: I - the edges of wood that have not been dried; II - the edges of dried wood; a, b, c, d - patterns of shrinkage of the edges of the wood, depending on their place in the trunk.

The initial stage of shrinkage is characterized by the release of the base from free water, there is a slight removal of bound liquid. The process takes place at a slow pace. At the moment of microcapillary water evaporation, the drying process is markedly accelerated.

Shrinkage changes the least in the longitudinal position of the fibers. Often this method is simply ignored. However, one cannot do without it if valuable wood species are taken into account.

The radial direction of this action is determined by the presence of many parameters. It depends on the type of tree species and on bulk shrinkage.

When working with wood, the term "shrinkage ratio" is used. It provides information on the transformation of tree parameters due to an increase in its humidity by 1%. A record is kept of the boundaries, ranging from feeding the cells of the tree to the process of removing moisture from them. For more accurate calculations of wet stresses, you should contact the professionals or the tables in the network, which impose such indicators to different breeds of natural raw materials.

The shrinkage rates of wood allow you to divide them into separate, rather large groups.

An important indicator of this lumber is the percentage of its density. It includes the weight of the product at certain moisture levels. This data can be obtained from formulas or graphically. So, with increasing humidity, density will also increase. Such a material has the highest density, the cells of which are completely filled with moisture.

Grouping of different wood types

Shrinkage of wood in different parts of the trunk.

The level of volume drying of the tree affects the division of natural species into the following categories:

- The degree of shrinkage is weak.

- Moderate volume reduction.

- Significant level.

- Intensive magnitude of change.

When a liquid appears on the surface of wood, it begins to increase in volume, swelling. As is clear, this process is the opposite of the sample in question. Similar phenomena are associated with the structure of lumber and their interaction with moisture. Swelling appears as a result of an increase in the moisture content of the raw materials up to 30%.

Some experts may state that the natural phenomena in question are negative indicators, but this is not entirely true. These excellent characteristics are used by winemakers, maintaining the unity of oak barrels throughout the long shelf life of alcoholic beverages.

During the construction process, wood shrinkage has an important function; these indicators should be taken into account when building any structure from this valuable material. Alternatively, it will become a model for flaws and flaws.

Tree shrinkage rates

Pine wood texture in three cuts: a - in the transverse; b - radial; in - tangential.

Due to the diverse nature of the structure of the sources under consideration, the percentage of shrinkage and swelling will be different, depending on the directions. Maximum indicators can be observed in the area of annual rings, this zone is called tangential. Its length corresponds to 8-12% after evaporation of moisture. Thus, the width of the board 100 mm after careful drying can be reduced to 88-92 mm.

A similar process associated with the radius of the trunk, known as radial, is 5-8%. The longitudinal direction of wood fibers corresponds to 0.1%, which is rarely fixed. The decrease in lumber volume indicators after drying corresponds to 12–20%, which is summed up by summing up the radial and tangent varieties of this process. Coniferous materials have small shrinkage rates.

Anisotropy, known as the difference in shrinkage of wood, affects the geometric dimensions of the rock. Often such a process is associated with a modification of the shape of the disc. As a result of the uneven shrinkage of a natural rock, its quality indicators may change. Here, the appearance of drying imperfections is possible, which can be seen after using a special camera. This technique is used most often.

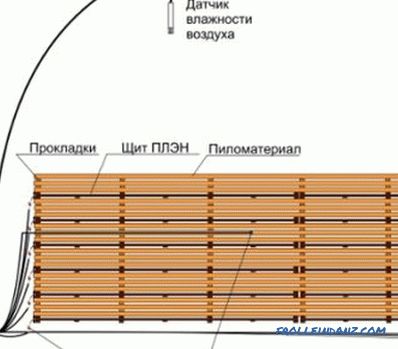

Organizations involved in wood drying are required to supervise humidity levels and temperature data in the chamber. Then the defective items will be much less. Currently, this production is set to automatic. The obtained indices of processing natural rocks remain the highest.

The installed temperature sensors practically do not give errors and give excellent results. In the production process of such equipment is used only the highest quality raw materials. The margin of error is less than 0.1%.

The lumber, after completing the drying process, must be of a certain size, for which the allowances for shrinkage are introduced.

Their permissible dimensions are based on numerous observations of the actual reduction of various tree species and correspond to GOST. These values can be found in special tables.

As a conclusion

From all of the above, it is necessary to conclude that the process of drying wood is inevitable. There is almost no lumber that does not undergo this process. Moreover, this phenomenon can carry both positive and negative points.

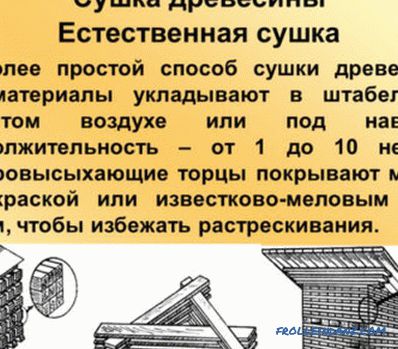

Drying of natural materials in a natural way will take a long time. The use of wet raw materials in the construction process will make the building uninhabitable until the process in question is completed. And this takes time.

You must wait for 12 months. The modern generation is increasingly trying to buy materials processed artificially. In this way, construction can be accelerated. When buying such raw materials, it is important to choose only quality options.

By giving preference to submitted samples, one should not save money. Otherwise, you can get an unreliable structure, which will bring a lot of problems in the future. Sawn timber should have special requirements. The base, built according to the requirements, will stand for many decades, recreating the original look.

Improper drying of the tree will lead to a rapid destruction of the building. Timber should not have uneven surfaces and visible flaws.

Didn't find the answer in the article? More information on the topic:

-

How to dry a tree qualitatively?

Recommendations on how to dry the tree yourself. Rules for proper drying of wood. Drying under atmospheric conditions. Advice of experts on drying wood.

-

Proper storage of lumber

Storage of lumber must be correct. It is best to store boards in stock. The material is laid on special lining bars. Laying on the ground is strictly prohibited.

-

How is wood treated with wax?

Step by step instructions on how to wax wood. Useful tips and tricks, materials and tools for work. How to prepare the surface? How to apply wax properly?