Many who begin repairs in their apartment, decide on redevelopment. This method will allow rational use of the territory of his apartment. However, often redevelopment affects the bearing walls. How to be in this situation? Is it possible to demolish the bearing wall? Or, is it possible to make an opening in the bearing wall? We consider the features of the supporting walls, as well as cases when they can be made an opening.

Is the bearing wall demolished?

House stability is achieved due to the presence of load-bearing walls, which are made of heavy-duty material. If one of the walls is removed, then the strength of the whole structure will be endangered. Due to the demolition of the wall engineering calculations will be disrupted. Conclusion: it is impossible to completely remove the bearing wall, it is fraught with great trouble. It is quite another thing - making the opening in the bearing wall. In some circumstances this is allowed. But this will require prior approval of the issue of redevelopment with the relevant authorities, carefully making calculations.

Features of load-bearing walls

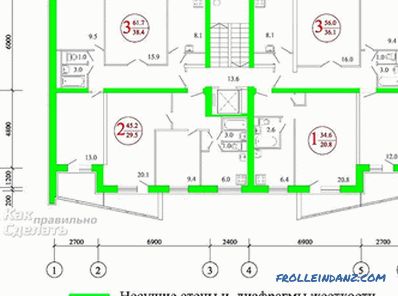

Plan of load-bearing walls of the floor

Plan of load-bearing walls of the floor

The thing is that the bearing wall is subjected to heavy loads. Therefore, because of how strong it is, it depends on the lifetime of the whole house.

Not in all cases, you can get permission to make an opening in the supporting wall! This is due to the fact that the design of houses in all cases may be different. It is especially problematic to get such permission if you live on the first or second floor. In these places, the walls are under special stress.

Some take the wrong position on this issue. They make an opening in the wall, and then in fact go to the authorities that they, they say, did not know or forgot to turn. But such people should be aware of the following. According to the latest rulings, the unauthorized making of an opening in the supporting wall can entail heavy fines, and in the worst case, the deprivation of the right to reside in this apartment. But this is the maximum that you can run into. At least in this case will force to restore the wall. Even if you managed to hide the fact of redevelopment, sooner or later they will know about it.

If you live in a brick house, then getting permission to make an opening in the supporting wall is easier.

So, to get the coveted permission, you will need to collect the following documentation:

- Floor plan of the apartment.

- Sketch redevelopment.

- The certificate of ownership of the apartment.

- Filling out an application in a strictly defined form.

If you do get permission, you can get to work.

The manufacturing methods of the opening and the necessary tools

Pick hammer

Pick hammer

With regard to the manufacture opening, many will think about a jackhammer. But this view is erroneous. Although this method is time-tested, it is not effective in all cases. Moreover, the use of a jackhammer for the manufacture of an opening in the bearing wall has several disadvantages:

- A large number of microcracks appears.

- The integrity of the wall is violated, especially if it is made of brick.

- The fabricated opening must be further processed, which will entail additional costs.

- In the process, there is a lot of noise and dust (you can't do it in secret).

- Many walls have metal fittings, making it difficult to work.

Preparation for dismantling

Preparation for dismantling

Today there are a number of modern technologies that allow you to quickly and Minimal labor costs make an opening in the bearing wall.

- Use of cable equipment. In this case, special sleeves and a rope are used, on which artificial diamonds are placed. This method is effective because it does not produce dust, vibration, or noise.

- Diamond drilling. Here special diamond-coated drills are used. They can be drilled even holes around the contour of the opening. Accordingly, this method will save your costs for the subsequent processing of the walls. The use of diamond drilling allows you to maintain the integrity of the wall as a brick, and reinforced concrete.

- Saws with a diamond dust. The most optimal way, if you want to find the best way to manufacture the opening in the bearing wall. There are two cutting methods: stationary and manual. The choice will depend on the size of the opening and the quality required.

Diamond cutting of openings

Diamond cutting of openings

Break not to build!

For Begin is necessary to carry out a number of preparatory processes. A jumper is prefabricated, which will take on all the main load from the above-located wall array. This element is very important: the safety of the whole building and yours will depend on its strength, respectively.In this case, the following should be considered:

- wall thickness,

- wall-to-wall size ratio,

- wall condition,

- material, from which walls are made,

- distance to adjacent walls and ceiling,

- arrangement of floor slabs,

- number of floors above your apartment.

In the case when the opening is made in a large-sized wall, the slabs should first be propped up. For example, props can be made from pipes or logs.

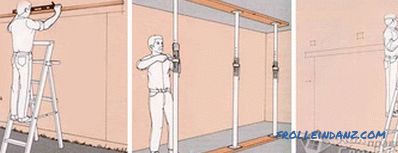

First, mark and make a temporary support

First, mark and make a temporary support

As for the material for the lintel, it is ideal steel is an option. It is the most reliable and sturdy material for this purpose. As a rule, you can purchase a channel that connects with bolts on both sides or an I-beam. If you chose to install the channel, then for its connection fit bolts M20. The distance between them should be half a meter. The length of the jumper should be sufficient so that it does not bend under heavy loads.

Now we proceed to making the opening. To begin with, the plaster is removed from the wall. To do this, you can first draw the outline of the opening with chalk. Then the opening for mounting the jumper is stitched. These strokes are made from two sides. Next, you need to drill the holes for fastening the jumpers with bolts. These niches should be well cleaned so that you can easily install a channel. Dust should be removed by moistening the wall with water.

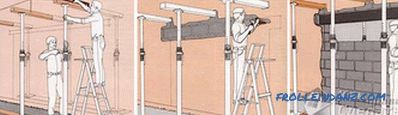

Dismantling the wall after manufacturing the reinforcing lintel

Dismantling the wall after manufacturing the reinforcing lintel

After the strobe has been manufactured, prepare cement mortar from the M500 brand. The solution should be dense and thick. It should be put in a manufactured shter, and after that, install the channel and tighten it with bolts. Now the whole structure should be properly frozen.

In the process, voids may form. How to eliminate them? To do this, you can take small pieces of the block / brick, which are installed on the same solution.

Bolted joints must have washers without fail!

Opening clearance

Opening clearance

After that, you can proceed directly to the punching of the opening. You can use any of the above methods. It should be noted that the penetration of the opening must be performed gradually. Consider how you will eliminate the formed garbage and how big the waste should be.

After the opening is made, the slopes should be trimmed. In some cases, it is possible to make reinforcement structures, especially if the opening has a greater thickness. To do this, the corners are mounted metal corner, which can be welded to the jumper. These corners are also welded together by metal plates. It remains only to plaster the slopes and proceed to the finishing finish.

Strengthening the opening in the load-bearing wall

Strengthening the opening in the load-bearing wall

There is another method to make a lintel from a reinforced concrete beam. By its strength, it is not inferior to the above technology. To install it, you must first make a through opening for the entire length of the concrete beam. She, in turn, fit into the cement mortar. Punching the opening is possible only when the cement with the beam grabbed. The subsequent process is similar to the above.

If you want to use non-standard interior design solutions for redevelopment, you can make an arched opening in the supporting wall. But in this case, you need to make a special design. For the manufacture of such an opening, it will be necessary to preliminarily prepare a profile or other material that will exactly repeat the outline of the opening. Fastening is carried out by the same principle. The only difference is that the structure as a beam should be bolted not only to each other, but also to the wall.

Arched opening in the supporting wall

Arched opening in the supporting wall

Weigh all and for the punching opening in the supporting wall vs. Remember that you must first obtain the appropriate permission.

We advise you to find out:

- align the walls under the wallpaper with your own hands;

- how to choose a punch for work.

Video

Detailed instructions for making the opening in the supporting wall: