Vacuum pumps appeared a long time ago and were previously used exclusively for industrial purposes. Now they have found application in everyday life. With the help of these devices it is possible to pump out vaporous and gaseous non-aggressive substances. The factory product costs a lot, so many thrifty owners make them themselves, using the available tools and materials.

In order to properly assemble a vacuum pump, you need to know how it works, which is based on creating a vacuum. All such devices are divided into physico-chemical and mechanical.

Varieties of pumps

Plate pump

Plate pump

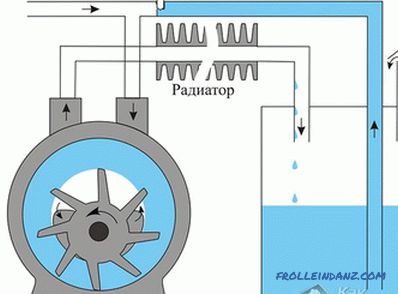

- Water ring. The decrease in pressure in such pumps occurs when the impeller seizes water. Centrifugal force causes the fluid to "run" along the walls of the chamber. The disadvantage of this mechanism and at the same time its essential element is the need for constant access to water.

- Rotary lamellar. An eccentrically located rotor rotates in a closed chamber, into the grooves of which a pair of plates is mounted. Moving in the direction of the walls, these plates capture a small part of the gas coming from the suction nozzle and move it to the injected hole.

- Rotary vane with four chambers. If one through plate is inserted into the groove of the rotor, then we have two cameras, but by installing four, we will get the same cameras. The principle of operation of such a pump is described above.

- Without centrifugal plate. The rotary pump can work efficiently without centrifugal plates. Moving partition should limit the amount of gas and its movement during operation of the acentrated rotor. This limiting obstacle should move progressively and change position when rotating the eccentric

- Pumps whose principle of operation is based on the movement of the membrane. The crankshaft is attached to the crank construction, which translates back and forth movements into it. The case is recommended to take from an unnecessary device.

Production

Detail of the vacuum pump It is recommended to start production of this product from the rotor assembly, for which we will need cylindrical washers from plastics having a specific size. To improve the shape and create a smooth surface, the rotor unit can be sanded.

Detail of the vacuum pump It is recommended to start production of this product from the rotor assembly, for which we will need cylindrical washers from plastics having a specific size. To improve the shape and create a smooth surface, the rotor unit can be sanded.

Now we proceed to the difficult work of making cavities. At the first stage, we make a template and mark the grooves. On the sides of the cavity can be processed with a conventional bench saw. Removing unnecessary particles of material in the inner part can be done by making a hole in diameter equal to the width of the slot.

In order for the landing chamber to be as smooth as possible from the inside, you need to process it with a file, and then sand it with sandpaper.

Making the plate

To get good plates, you need high quality plastic strips. The cavities of our billet must be carefully processed, and lubricating fluids must be used to prevent friction.

There is a small secret that can simplify the fixing of the hose - it is necessary to attach the fittings to the thread located at the inlet and outlet openings. If you used this method, you will need to check the operation without the drive being turned on. Do not forget about high-quality seals that prevent leakage at the joints. How to make a vacuum pump in other ways, we describe below.

Water ring vacuum pump

Water ring

Water ring

For this homemade device we will need a cylindrical case in which it is necessary to place a shaft with an impeller mounted on it having small blades. Care must be taken to ensure an uninterrupted supply of water to the unit, which will rotate our blades. Centrifugal force will force the liquid to rush to the walls, with a vacuum forming in the center.

The car pump is turning. ..

We convert the automobile pump

We convert the automobile pump

For making a vacuum pump, automobile or bicycle modifications are suitable. The first stage of our process includes the promotion of the selected pump, reversal of the cuff 180 degrees and the reverse assembly. Turning the clutch over will allow air to be drawn out of a specific container.

In the second stage, we need to install a check valve between the pump and the hose.

As a result, we told you a few simple ways to make a vacuum pump. Now everyone can make this simple device independently with the help of our recommendations.

Video

Example of manufacturing a vacuum pump: