The room of the steam room is traditionally considered to be the key one in the Russian bath, since the functionality of bath procedures, renowned for their beneficial and healing properties, depends on it. In the article we will talk about how to properly make a steam room in the bath with your own hands, how to equip the ventilation, the floor and the shelves.

The manufacturing process of the steam room can be divided into several working operations of the following content:

- room insulation;

- furnishing of the furnace and ventilation;

- finishing.

Thermal insulation

Thermal insulation of the steam room

Thermal insulation of the steam room

Steam insulation material The main indicator of the performance of the steam room is a consistently high temperature, which is almost impossible to maintain without good thermal insulation. That is why the insulation of the steam room is considered the most important procedure in the whole process of its arrangement.

Steam insulation material The main indicator of the performance of the steam room is a consistently high temperature, which is almost impossible to maintain without good thermal insulation. That is why the insulation of the steam room is considered the most important procedure in the whole process of its arrangement.

When the insulation is poorly performed, the steam air in the room will heat up very slowly and cool quickly, and the steam will have a very low concentration.

When warming a steam room, various materials are used, each of which performs a specific function, and the absence of any of them leads to a drastic decrease in the quality of insulation. As a result of this distribution of functions, a multi-layer protective coating is obtained, which includes the following successive layers:

- waterproofing layer;

- insulation layer;

- vapor barrier material;

- inner lining.

The waterproofing of surfaces (walls and ceiling) of the steam room is done by covering them with a layer of waterproofing material, such as foil, for example, or plastic film.

It is recommended to start arranging the heat insulating layer with mounting on the surfaces of walls and ceilings of unpainted plain paper, over which a frame of wooden bars is stuffed, which serves as a base for the placement of plates of heat insulating material. On top of the insulation material is covered with a layer of vapor barrier, which is most often used conventional aluminum foil. Then a wooden frame is made of wooden bars, which is subsequently sheathed with clapboard.

The ceiling should be better insulated than the walls, so the layer of insulation material on it should be thicker.

Video

Example of a device for heat and vapor insulation:

Furnace and ventilation

Bath stove

Bath stove

Ventilation in the bath The “soul” of any Russian bath is, of course her stove, thanks to which pair procedures are famous for their health-improving properties. For the construction of the furnace, it is recommended to use materials from the following list:

Ventilation in the bath The “soul” of any Russian bath is, of course her stove, thanks to which pair procedures are famous for their health-improving properties. For the construction of the furnace, it is recommended to use materials from the following list:

- red kiln or fireclay bricks;

- natural stones;

- cast iron plates.

If you wish, all these materials can be used in a comprehensive manner, since brick is a good stove for stove heat, stones will allow you to get steam, and heated cast iron plates have high heat transfer. With such use of heat-accumulating properties of raw materials, the resulting furnace can "hold" heat for 12-15 hours (at temperatures up to 85 degrees). But this, of course, depends on the quality of the insulation.

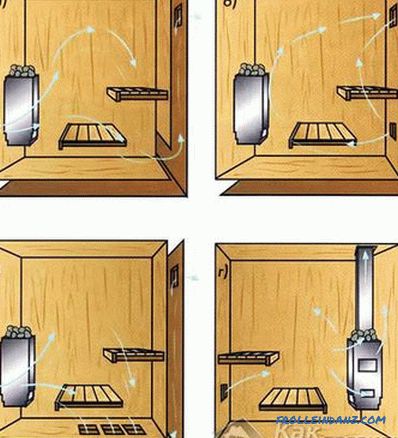

In the room itself, a special window for ventilation is usually not done. The ventilation window should be made in the waiting room, and already from it fresh air will flow into the steam compartment.

Video

Here are considered typical errors of ventilation and the most universal scheme of working ventilation:

Finishing

Finishing of the steam room

Finishing of the steam room

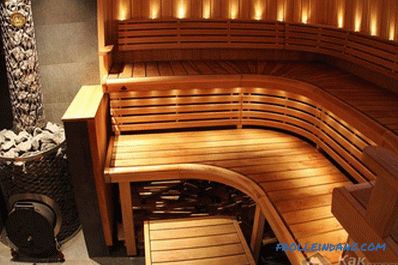

The interior of the steam room is made immediately after the completion of the main construction operations and is usually performed using wood materials that are resistant to high humidity and temperature For decoration, you can use a variety of tree species, but it is best to close the walls with linden or alder, and lay the floor with material from larch. Shelves made of linden, when heated, will produce a unique aroma containing various natural enzymes. They have a beneficial effect on the person.

After finishing, the wooden walls of the steam room are thoroughly polished and left in their natural form.

Design of a steam room

Design of a steam room

Design of a steam room

Deciding how to make a steam room, due attention should be paid to its design. When you make your room, you should consider the following expert advice:

- walls, floor and ceiling in the steam room should be left in its natural form, without resorting to any coatings. In this case, wooden surfaces will heat up much faster;

- shelves and benches in the steam room look more aesthetically pleasing if you place them at different levels.This is also convenient from the point of view of their functionality, since at different heights you can choose the right temperature for you;

- you can add elegantly decorated towel racks and brooms for styling the interior of the steam room, as well as decorate the doors with an original pair frame and beautiful handles;

- as light sources it is best to use lamps with a dim and soft glow, placing them above the entrance door.