Perhaps, every master knows how much faster and better work can be done if tools are used for this purpose. Of course, some types of work can be performed with the help of available tools, but often this process is fraught with considerable risk, and it can be difficult to call it convenient. For example, when carrying out certain types of carpentry work (sampling grooves, grooves, grinding, facing) can not do without a milling machine. Of course, the modern market does not experience a deficit in anything, and buying such a device is easy, but it is worth noting that the price of such mechanisms is far from small. There is a way out of the situation, but for this you need to know how to make a milling machine yourself.

Where to start?

If you decide to make your own milling machine, be aware that this job will require certain basic skills, as well as accuracy and accuracy. As in most similar cases, before proceeding to the direct manufacture of the machine, you need to make a detailed drawing of it. If you have enough knowledge, you can do it yourself, if not, then order it. You can use ready-made drawings. All subsequent work must be carried out in strict accordance with the drawing.

Framework

In general terms, the milling machine, both self-made and factory-made, consists of a metal frame that performs the supporting functions, a wooden or metal tabletop and an electric motor that drives the whole mechanism into action. As the material of manufacture, you can use a metal corner or a shaped tube. Although it is possible to perform the frame and wood.

Cover

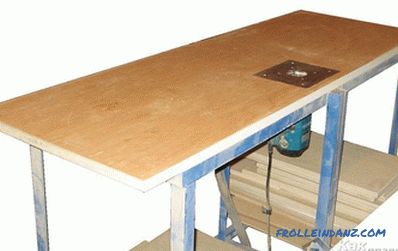

Table with a technological hole

Table with a technological hole

Another component of the milling machine is the top cover. For its manufacture, you can use a thick plywood or edged board, which must be further processed to the surface was smooth. In the central part of the tabletop must be made technological hole through which the shaft of the electric motor will pass.

Electric motor and suspension

The next stage of work on the manufacture of a milling machine is its equipment by an electric motor. Here is one of the main points that are worth paying attention to is the power of the motor. It has been experimentally established that for most household work on a household scale, a motor with a power of 1200 W will be suitable. In principle, it may be enough and less power, but it is better to have a reserve, and working with a powerful engine is more comfortable. As for the installation of the motor, the best option would be to mount it on a special suspension, adjustable in height.

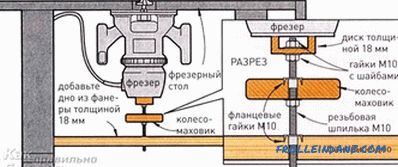

Suspension scheme

Suspension scheme

The most optimal variant if the cutter is mounted directly on the motor shaft .

Additional elements

In order to make the work at the machine even more convenient, it can be equipped with some additional elements. For example, you can perform the upper clamp, which will fix the workpiece. And also it will not be superfluous to equip a system for collecting dust, which can be adapted as an old vacuum cleaner.

Dust removal system

Dust removal system

In conclusion, you can add that a homemade milling machine, if its correct and make a high quality, able to perform all the functions assigned to it no worse than the factory. In this case, funds are saved quite substantial.

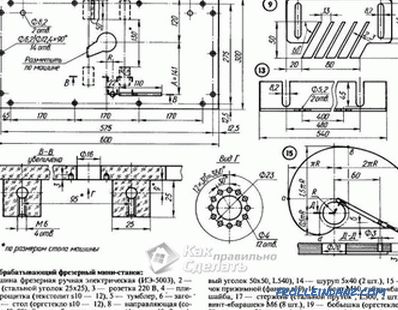

Schemes

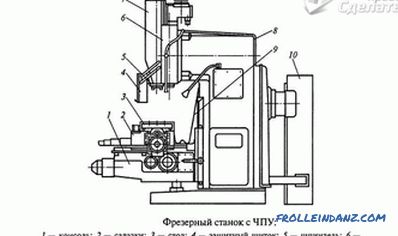

Drawing of a CNC milling machine

Drawing of a CNC milling machine

Drawing of a woodworking machine

Drawing of a woodworking machine

Video

Watch the video footage that will help you assemble the milling machine yourself: