For many millennia, wooden houses have been used by people, and their popularity in the 21st century is reaching a new level. Before you add a log house from round timber, you need to know a lot of things. There are many advantages of this kind of houses: environmental friendliness, design, it warms up easily and retains heat for a long time, breathes, so that there is always fresh air inside.

Parameters for building a house from a bar.

Preparatory work

Tools and materials:

- tape measure;

- shovel;

- sand;

- water;

- edged board;

- reinforcing rod;

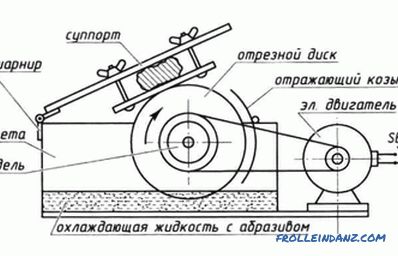

- Bulgarian;

- welding machine;

- hammer with nails ;

- gas burner;

- roofing felt.

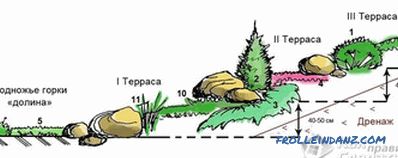

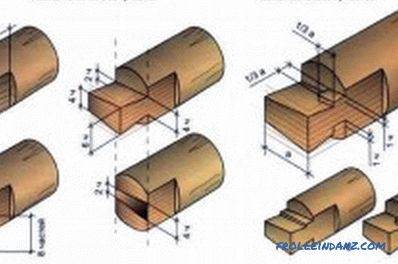

Scheme of a log cup with an angle cut.

At the very beginning, a foundation is made below the log house, and its depth may be minimal, but it will have to be raised above the ground high enough so that seasonal moisture does not destroy the wood. The shallow-tape foundation is optimally suited for which it will not take a lot of time and effort.

To begin with, a trench is dug around the perimeter to a depth of 35 cm and to a width of 40 cm, with at least 2 rafts forming inside to increase strength. After the required trench has been dug, its walls and the bottom part need to be leveled, thanks to which the solution to be filled in will be distinguished by high reliability.

A sand cushion of 5 cm is poured at the bottom and poured over with water. In the meantime, the water dries (2-3 days), you need to prepare the remaining elements.

Now the formwork should be made. It will require an edging board 25x150 mm, and the height of the boards will be 0.7 m. It is advisable to make the formwork directly to the entire building so that later you do not have to fill it with parts. All boards are mounted on nails, since the screws will have to spend 2-3 times more time in order not to split the boards.

A 10 mm ribbed rod goes to the reinforcement cage. In this case, the process looks like a standard image:

Figure 1. The layout of the log when cutting into a paw.

- 5 long parallel rods are laid out in 10 cm steps.

- Rods are laid perpendicularly 60 cm in 30 cm steps.

- Each joint is fixed by electric arc by welding.

- An identical grille is made.

- With the help of 25 cm rods all parallel joints are combined into one system. It is advisable to carry out this step directly at the installation site, since even 2 people will not always be able to lift the finished structure, and not everybody can use the crane.

When manufacturing, you need to be careful that the metal does not touch the formwork and sand. In order to raise the reinforcement above the sand, you need to use broken bricks or special plastic stars. Top need to weld the rods in 1 m increments in order to ensure high-quality joint between the round timber and concrete.

Now you can pour the concrete solution M300-350, after which you can safely leave for drying for 28 days. After this time, the formwork is dismantled, and all open areas of concrete are laid with roofing felt and burned with a gas burner. Steel rods also need to cover waterproofing.

Main activity

Tools and materials:

- ax;

- round timber;

- tape measure;

- knife;

- tow.

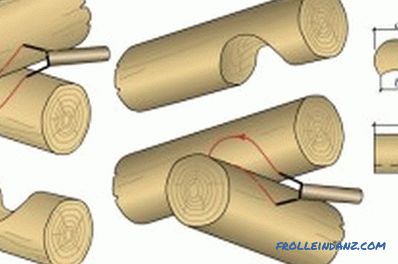

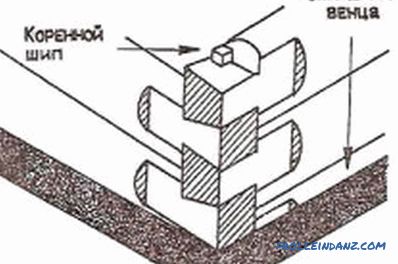

Figure 2. Connection scheme in a paw with a spike.

Now you can make a log of round timber. There are only 2 options for felling, which are particularly popular: Russian and Canadian. Outwardly, the result is identical, but in practice the Canadian bowl (fig. 1) is universal, since it allows wood to be harvested in any season, and after shrinkage (up to 10 cm) no cracks appear. There are 2 ways of cutting - in the bowl and in the paw (Fig. 2), but because of the reliability, the bowl is particularly popular.

There is a small nuance that not everyone adheres to, which is why the tree is sometimes judged negatively: it is necessary to form all the elements with an ax, because in these places the likelihood of decay decreases many times. In no case can one use rounded variants, since during industrial processing the protective layer is removed from the wood. The only plus of the rounded version is its thermal insulation, which is the best of all analogues.

Glued laminated timber is an intermediate link, i.e. it possesses intermediate strength characteristics, and at the same time it has average thermal insulation and weight. It differs in a way of a joint - vertical. This method does not require cutting the grooves along the edges, since it has a continuous groove along its entire length, into which the next similar specimen can be installed.

Scheme of the vertical section of the inter-joint connection.

After the whole log house has been made, you can begin to cut down the doors and windows.Such a step is very unusual in modern realities, but it is he who will provide the perfect quality. For strength, you need to center one log in the center.

The house is ready, the windows and doors are installed, the roof is covered, but you need to finally distinguish between internal and external space. For this purpose, all the slots in the log house are caulked. This process is carried out with an ordinary knife. Any finishing is fixed on top, but in the first 3 years it is better to use something simple, since you need to follow the seams.

Additional aspects

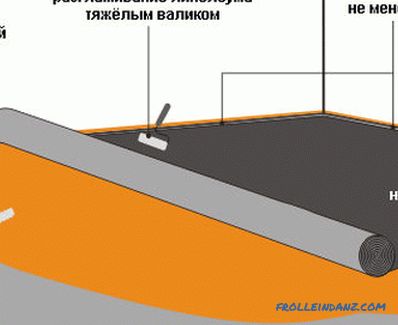

Floor insulation is expanded clay, but you can use any other insulation if you wish. For the claydite, a waterproofing is initially laid on the ground, which will penetrate the walls, then there is a layer of insulation, and then waterproofing again, but already with a bend down. A screed is formed on top.

The furnace inside is placed at a distance of at least 15 cm from the walls, but it is better in the old traditions in the center of the room. Such a precaution will not worry about possible fires.

Before you add a log of round timber, you need to know not only the quality of the wood, but also the time of cutting.

To be sure of the quality, it is better to take the simplest round timber of the chopping house, which does not go through special tool treatments.

It is he who will serve several centuries, if done correctly.

Didn't find the answer in the article? More information on the topic:

-

How to self-level the floor quickly?

How to level the floor quickly? To do this, you must know the styling technology and the sequence of steps. To achieve the desired result, you should know the basic types of base smoothing.

-

How to mount the wall panel to the wall

Fastening the wall paneling to the wall: crates. Materials for mounting the frame. Several types of fasteners and how to use them. Photos of individual work moments.

-

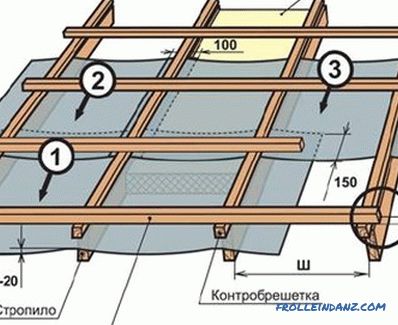

Features of the roof lath

Roof lathing do it yourself: the main varieties of pitched roofs. Creation of a framework for rolled material and under a soft roof. Technology and installation features.