In this article, we will acquaint you with how to properly make a wooden ceiling on the ceiling beams with your own hands, and also tell you about the general procedure for holding events of this type.

Immediately, we note that the wooden flooring along the beams is used, as a rule, only in private suburban housing construction and is settled either between the floors or between the room and the attic. This type of floor has several advantages not only in comparison with standard reinforced concrete blocks, but also in relation to monolithic type floors.

Wood floors

Wood floors

These advantages are as follows:

- wooden floors are easily erected and do not require any additional technical means (a crane, for example, or special concreting equipment);

- they are much lighter than their counterparts, made of known building materials;

- with The use of such ceilings may make the foundation foundation somewhat lighter.

Beam slab

Beam slab

In addition, it should be noted the relatively low cost and high speed mounting this design element. The disadvantages of overlapping of this class can be attributed only to their high fire risk and the possibility of destruction by the bark beetle. In addition, they are distinguished by lower sound insulation than concrete structures, they are sensitive to changes in temperature and humidity of the surrounding air.

However, you can always eliminate these disadvantages if you apply special impregnations that significantly reduce these risks.

Main characteristics of beam ceilings

Material for beams

Material for beams

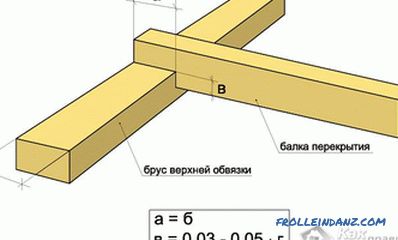

For the manufacture of floor beams ordinary solid wood is used. With the same success, more durable glued samples are used, the length of which is allowed to increase to 15 meters. Both coniferous and deciduous species of wood can serve as the material from which beams are made. The distance between adjacent beams should not exceed one meter. Beams with a length of 2.5–4 meters (with a ratio of height to width of their cross section - 1.4: 1) are considered the most optimal for spans of typical residential buildings.

The choice of beam section in the most general case is determined by the load on which this overlap should be calculated. In order to increase the bearing capacity of such structures, beams are placed, as a rule, along a short wall.

Beam slab dimensions

Beam slab dimensions

As a design variant of such beams, you can consider the case when they are simply lined with boards from the top. The lower parts of the beams, open to public viewing, contribute to the creation of a certain style in the design of this room. If desired, you can also sheathe them and make a typical suspended ceiling.

Correct decision of the main question "how to make a wooden floor correctly?" also includes a limitation regarding the maximum length of the beams.

The length of the floor beam between residential floors should not exceed 5 meters, while for floors between the residential floor and the attic, this figure can be up to 6 meters.

Installation of the ceiling

Waterproofing of beams with roofing felt

Waterproofing of beams with roofing felt

Installation of floor beams usually done in the following order:

- Before laying the finished beam into the wall niche, its ends are wrapped with two layers of roofing material, and the length of the waterproofing layer is selected with a margin (but not less than 25 cm). After that, it is pushed into the wall and placed there in such a way that the inner edge of the ruberoid protrudes 2-3 cm.

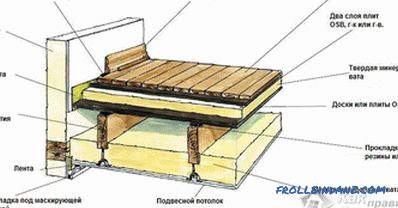

Insulation of the ceiling

Insulation of the ceiling

- Next we turn to the insulation of the ceiling, for which we can choose ordinary mineral wool or natural material similar to it (sawdust, seaweed, etc.). Foam for these purposes is not recommended, because this material is not breathable. You can use for warming and conventional claydite, but it is necessary to take into account the fact that the latter gives an increased load on all elements of the constructed structure.

- Laying (backfilling) of the insulation is done immediately after you have closed the beams on the underside with the finishing material of your chosen type. From above, the flooring is usually made of planed tongue-and-groove boards, which is also the floor for the upper floor.

- After you have laid the void with insulation, you will need to worry about waterproofing the floor itself. To do this, you will need a waterproofing film, which will need to be laid and fixed on top of the insulation.

In the interior of

In the interior of

- After closing this whole structure with a finished floor, your ceiling will be completely ready.

Video

From the following video, you will learn how professionals put overlaps and calculate the number and size of beams for the flooring: