Today, craftsmen often use self-made equipment. At the same time to reduce the cost of such, you can successfully use plywood, having made of it some parts of home-made machines.

To avoid dust when working with the machine in a room, install a safety fence.

Plywood properties

Plywood is a very versatile material. It has sufficient strength, is easy to use, generally accessible and relatively inexpensive. That is why plywood is often used not only for the manufacture of furniture or decorative items with their own hands, but also to make home-made machines.

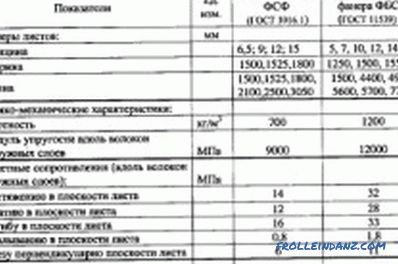

Physical and mechanical characteristics and sizes of construction plywood of the types of FSF and FBS

Some parts of the machine can be perfectly replaced with parts made of plywood. For example, a plywood table is perfectly used for cutting material, housings and movable pillars made of plywood, also proved to be remarkable in use. And this is not all the details that can be made of plywood, in order to make a machine with your own hands.

When choosing a material, it is worth starting from the load on which plywood and parts are calculated from it. In most cases, making a homemade machine, it is best to use plywood of medium thickness. So, homemade machines are designed for use in the home without temperature differences and humidity. Thick is used if the machine or its elements, for example, a table for cutting material, require increased strength, then it is better to use a more durable, with a thickness of 10 mm. However, making any home machines, it is initially worth refusing to use thin plywood, because it is too fragile for such work and unsuitable for use in the manufacture of homemade machines.

When cutting parts up to 6 mm thickness, a manual or electric jigsaw can be used. If there is a need to cut a thick sheet exceeding the thickness of 6 mm, a circular saw is used.

When cutting plywood across the fibers, special cuts are made with a knife in order to relieve tension on the wood.

How to make a homemade machine out of plywood?

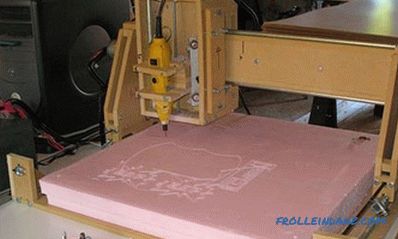

It should be said at once that this is a home machine, which is hardly suitable for working conditions, but for a house it is the best balance between price ratio and quality given the relatively small load on it. To make a homemade machine out of plywood, we need machines for various needs, but the CNC machine is most popular.

In order to make a CNC machine out of plywood, you need not only plywood itself, but also other tools and materials:

Accessories for assembling the machine need to purchase in advance at any hardware store.

- special shafts and holders;

- various bearings;

- screws;

- controller;

- belts and fastening elements in the form of screws, nuts, screws and washers.

For cutting and cutting you will need:

- a ruler, a square;

- a knife;

- a jigsaw or a circular saw based on what thickness plywood will be applied.

Since CNC machines assume the use of parts in which plywood is cut out and should fit very closely to each other, so that there is not the slightest gap, then approach the cutting and sawing, making the future machine, stands very responsibly and following certain rules.

When making your own machines for home use, you need to remember that this material does not tolerate strong mechanical stress. Therefore, the fastening of parts is carried out by using grooves and spikes, which are additionally coated with glue for strength. In order for the connection to be reliable, the tongue and groove must fit perfectly together without any gaps or cracks. No nails or screws can be used as fasteners. Machines and their parts made of plywood are subject to vibration in the process of work and, if improperly fastened, can fall apart at the crucial moment, therefore special attention must be paid to the fastener.

Since, when making machines with plywood parts, you have to use a drill, you must also observe a little trick so as not to spoil the material. In order to prevent chips from forming at the point of the drill exit, another piece of the same material should be placed on the other side under the worksheet, it is optimal to use plywood residues after cutting and cutting.

It is easier and quicker to use jigsaw for cutting parts.

After the parts are cut, they must be processed, otherwise the plywood may begin to delaminate and collapse.Particular attention should be paid to processing the edge, which is most susceptible to the effects of temperature or humidity. As a rule, initially every detail needs to be thoroughly sanded with fine-grained emery paper; polishing should begin from the corners along the fibers. The corners are treated with sandpaper separately, they are given careful attention, if necessary, they can be touched before processing.

After thorough grinding of all the parts with fine-grained emery paper, it is possible to proceed to their priming with a special compound that prevents from exposure to temperature and humidity differences, as a result of which the plywood may begin to delaminate and disrupt the machine. At the final stage, which is done at will, you can paint the details of the machine from plywood.

Tips for correctly cutting plywood

Be sure to cut dry material because it is less susceptible to resistance. Using wet plywood can lead to delamination.

If there are signs that the teeth in the cutting blade have become blunt, it should be changed immediately, this will help avoid cracking and an ugly edge, as well as material damage.

Along the fibers, it is best to work with an electric jigsaw, but with cross-cutting, a hand file is more suitable, although it will make the edge more uneven, but it guarantees the absence of tool clamping or moving away from the intended cut line.

When working with thick plywood, it is best to use a furniture mill for cutting an arc or a circle. In order to avoid chips and other damage as much as possible, it is best to glue tape to the place of the future cut, and then cut the plywood.

Didn't find the answer in the article? More information on the topic:

-

How to choose the right drill driver?

How to choose a power screwdriver so that it works long and reliably. What are the batteries for the specified tool, their main advantages and disadvantages.