An excellent method of restoring a damaged wood floor is to scrape the surface with further varnishing. However, scraping a wooden floor is expensive and time consuming work. Before you take up the scraping, you will need to calculate the costs.

Scraping returns the old floor to the previous state, after which it looks like a new one.

In order to do a floor scraping with your own hands, you will need to purchase the following elements:

- A drum sander. Used to clean old varnish and level the surface. Rental price - 800-1000 rubles / day.

- Surface grinding machine. Used for finishing sanding before varnishing the surface. Rental price - 800-1000 rubles / day.

- The machine for grinding corners. Used to strip the edges of the floor base. Rental price - 400-600 rubles / day.

- Industrial Vacuum Cleaner. Used to remove dust from the base before varnishing.

- Sandpaper for stripping, finishing sanding and removing wood pile after varnishing the surface.

- Discs for grinding machine.

- Putty for parquet without filler.

- Varnish for parquet.

In the next step, it is important to check the condition of the electrical wiring in the apartment. Please be aware that grinding machines consume at least 1.3 kW. Such designs form a lot of noise. An alternative option may be manual shredding, which does not produce noise and dust. However, you should be aware that it may take 12 hours for a 10 m² trim.

The process of scrubbing a wooden floor

It is important to know the following:

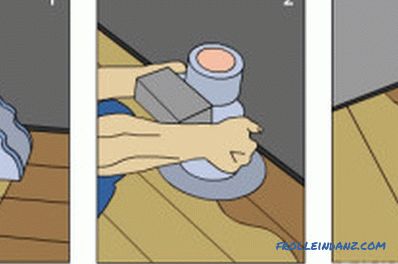

The scheme of manual scraping.

- For a scrambling drum, use a special pelt. On the wrong side of the skin, the direction of refueling will be indicated by an arrow. It will be necessary to refuel on this reference point. Rolled structures are used extensively, and therefore the eccentrics, which fix the skin, often scroll. To eliminate such a defect, a spacer is enclosed under the eccentric.

- The scraping machine must work continuously and evenly, otherwise the construction will make a hole in the floor. Before turning on the machine, it is necessary to raise the disk or drum, wait until the work item has gained momentum, and then start moving, gradually lowering the drum or disk. Stops the machine in reverse order.

The basic rule of scraping parquet is to prevent continuous movement across the fibers of wooden elements. In most cases, this leads to the splitting of wood. Floor scraping has some peculiarities:

Wood floor scraping scheme.

- Parquet cleaning from straight-layer planks, which is laid with herringbone, is carried out at an angle of 45 ° to the planks. Fine grinding should be done along the boards. Each operation is performed in several visits.

- The scraping of the floor, which consists of curly boards, is carried out in several perpendicular directions. Each operation is performed in 2-3 visits.

- The scraping of the decorative floor is carried out with smooth movements in a circle from the extreme part to the central part. All actions need to be performed solely by using a surface grinder. An abrading is performed in several passes, while it is impossible to linger in one place.

- Elements of artistic parquet are in most cases made from wood of expensive species. Such parquet is looped exclusively by professionals. In this case, you need to use a small machine for grinding angles, the movement should be performed in a circle. In the process of scraping you need to take into account the pattern pattern and the properties of individual elements of the tree.

The correct sequence of actions for scraping parquet

Doing a wooden floor with your own hands as follows:

Example of floor before and after scraping.

- The furniture is taken out, the baseboards are dismantled, the floor is swept up with a dry broom. After that, the floor base should be vacuumed with an ordinary vacuum cleaner.

- The coarse sandpaper is tucked into the drum. After that, sandpaper need to walk several times over the entire area of the base. Work needs to start from the far wall, slowly approaching the base, which is used most often. Dust from a special container of the vacuum cleaner should be poured into a plastic bag.

- Varnish stains that may remain should be removed with slow circular motions from the extreme part of the base to the central one. In this case, use a machine for grinding corners.

- With the same device it is necessary to strip the varnish in the corners and niches, making pendulum movements from the border of the treated base to the wall.

- Finishing sanding parquet should be performed with a surface grinder.First you need to walk on the base of the floor surface. After this, the machine for grinding corners should be walked through the corners and niches, if the processed border appears.

- After that, you need to collect all the formed dust.

- In the next step, the base of the putty mixture is kneaded. Using a putty spatula, you will need to evenly fill the entire base of the floor surface.

- After the putty has dried, you need to iron the floor base with an emery paper drum. In inconvenient places you should use a machine for grinding corners.

- The floor is varnished. After the varnish is completely dry, the drum with an emery paper will need to remove the pile of wood that has risen. Inconvenient places in this case also need to be processed with a machine for grinding corners.

- Several times it is necessary to pass the floor, walls and ceiling well with an industrial vacuum cleaner.

- The floor base is varnished in several layers, each of which is processed exclusively after the previous one is completely dry.

Some recommendations you should know:

- It is recommended to use a microfiber roller for varnishing. High-quality varnishing in several layers can only be obtained by using a similar roller. It is expensive, while it can only be used once.

- Finishing sanding is performed with an emery paper drum.

The natural deflection of the boards should be equal to a maximum of 1-2 mm, but its radius can be compared with the radius of the drum.

How is manual chipping done?

Manual chipping should be done with a cycle (the iron part of the planer). First of all, the iron part must be heated on a gas flame to a red glow, and then allow the device to cool slightly. The heating process takes about 10-15 minutes. The iron element should be clamped in a vice along with a part of the pipe. The device bends with weak hammer blows.

Next, the blade will need to be heated again, then immersed in water.

The performance of manual scraping can be improved several times. To do this, use a scrub - a special device that is used for stripping seams in the casing. The edges of the scrub need to be made smooth, for which you should use sandpaper.

Do-it-yourself wood floor repair is a time-consuming process.

You should know that to restore the floor base with a scoop will not work in all cases.

It is best to entrust such work to professionals.

Didn't find the answer in the article? More information on the topic:

-

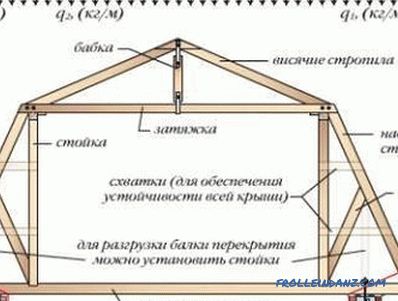

Installation technology of the truss system

Step-by-step instructions on how to install the truss system. Technology arrangement truss roof system of the house. Preparation of walls and floors of the house.

-

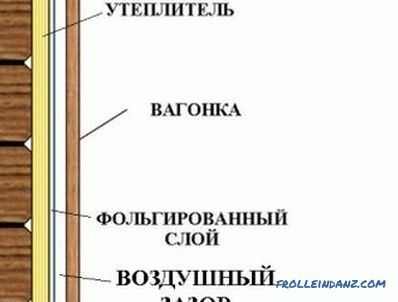

What and how to sheathe a wooden house?

Recommendations on how to sheathe a wooden house. Features preparatory work. The choice of insulation and exterior finishes. Vinyl siding installation.