Formwork for the foundation is quite simple. Although there are some subtleties that must be taken into account. Before starting work, you must read the instructions for its installation. The instruction will allow to carry out the work much faster and avoid common mistakes.

Device

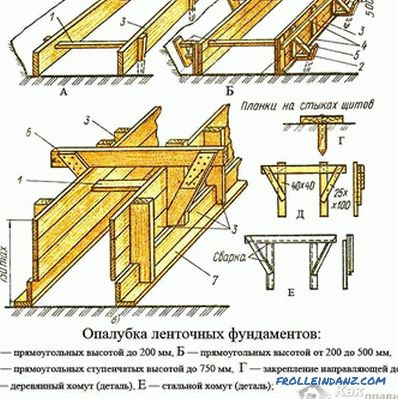

Formwork for strip foundations

Formwork for strip foundations

Formwork is a special collection of parts which is designed to produce monolithic blocks. As applied to the foundation, it can be said that in this case it makes it possible to create that part of it that will be located above the ground.

Decking is of two types:

- removable;

- non-removable.

The first type is usually made of planks or metal. The second type is made of polystyrene foam.

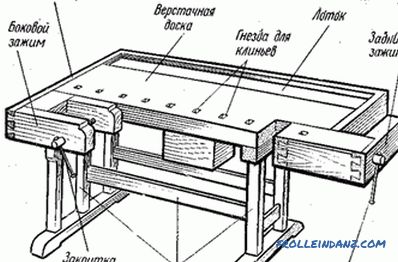

Decking is a standard construction. In other words, all types of formwork are similar in general terms. The simplest design of this type is created with the help of boards, beams and nails.

Simple formwork

Simple construction

Simple construction

The formwork for the foundation is usually made from planks . This is an economy option that suits many builders.

- In order to make such a construction, only boards, planks and nails are needed. You can also think about the props.

- Along the perimeter of the foundation it is necessary to drive in strips (pegs). From the inside, a board or plywood is stuffed on the slats.

- The installation of the formwork should be done so that the future outer walls of the foundation are not curved or sloping. Otherwise, the walls will turn out wrong. It is better to work with the level.

Additionally installed props will make the construction more even.

A mixture is poured between the walls of the formwork. Boards can not be removed until the mixture dries.

Ready-made solutions

Ready-made option

Ready-made option

Today there are ready-made solutions in stores . This formwork has a number of advantages:

- the master does not have to waste time on the manufacture of the structure;

- the formwork made under production conditions has no errors;

- this structure much stronger;

- the finished formwork can be wooden or metal;

- the master can order the structure according to his own calculations.

The finished formwork, of course, will cost no less. But at the same time the master does not have to work and measure out all the components. Correction of deficiencies caused by the use of low-quality slats, may cost more.

Fixed

Fixed formwork

Fixed formwork

Where on the foundation have a very high load required fixed formwork.

This type of formwork is beneficial for several reasons. Non-removable design reduces heat loss. It also allows you to save on materials. Using fixed formwork, you can not worry about the basement.

Styrofoam, laid next to the formwork, protects the walls. It prevents the ground from freezing, and this creates a safe environment for the walls.

For strip foundations

Correctly made formwork

Correctly made formwork

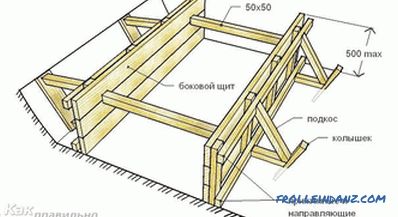

Usually in this case boards and supports Boards should be about 50 mm thick. The height of the formwork can reach 2 meters.

The installation of formwork for strip footing begins with guide boards.

If the construction is very high (more than 2 meters), then instead of boards it is better to use panel materials. To ensure proper strength, the width of the shield must be equal to the height.

There should be no slots in the formwork. Of course, they inevitably arise, but the master must close them up. Before pouring the mixture, small gaps are filled with tow, and large ones are masked with special rails.

Work complexity

The construction process

The construction process

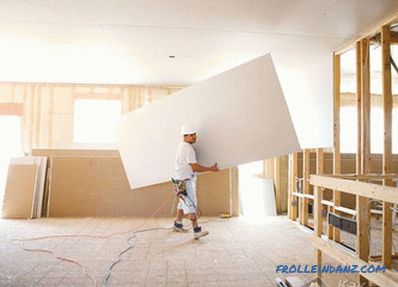

Formwork installation is a laborious task. The master must understand all the details of this process. Many beginners only after pouring the structure begin to wonder when to remove the formwork from the foundation. If the builder does not have time for such subtleties, then it is better to immediately turn to specialists.

What particular details you need to know before starting to work:

- It is imperative to choose which type of formwork will be used in a particular case. For example, removable formwork is most often installed when there is no need to warm the walls of the basement. In regions where severe frosts prevail, this type of formwork is not a good choice.

- The formwork design depends on the foundation under it. Depending on the type of foundation materials are selected for construction.

The fineness of the fill is still half the point. The master must clarify the composition of the mixture poured. To do this, find out what brand of concrete is used for the manufacture of structures, and whether to add other materials there.

Tips

Construction of formwork

Construction of formwork

Someone thinks that the construction of formwork is just nails and a pair of boards of the right size. This is partly true because the formwork is only one of the transitional stages from arranging the foundation to the walls of the building.

However, today there are quite complex systems where a pair of boards is indispensable. This is a formwork for walls. Thanks to such a system, modern architects manage to create truly grandiose structures.

Recently, film formwork has become popular. This view implies wrapping the structure with a film material. Thus, you can achieve the necessary savings in construction.

Decking is done over a couple of days. This is the time it takes for the concrete to dry. During this period, you should not disturb the structure in order not to break its symmetry. Boards with formwork should be removed carefully, after checking the condition of the walls. In some cases, it takes three days to dry the concrete.

Video

We offer for viewing video materials about the construction of formwork.