The foundation of any home must be strong, reliable, durable. The microclimate inside the building will depend on these indicators. As the statistics show, up to 20% of heat can be lost through an unheated foundation, so this issue should be approached with special care. Warming up the basement of the house is foreseen before the construction, as it is necessary to choose insulation and lining material. This article will consider all the nuances regarding how to warm the basement of the house with your own hands, without the involvement of professionals.

General information about the base

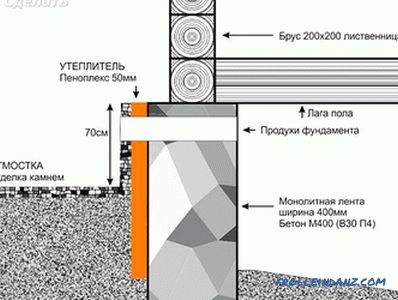

The construction of the basement of a private house is such that all girder floors of the first floor are based on it. The main part should be underground, so the outer part protrudes no more than half a meter. It is this part with the wrong insulation or its absence can lead to large heat loss.

In order to avoid this, in modern construction they devote a lot of time to technology and the choice of material for basement insulation. This will minimize the heat loss. When designing, in most cases, the process of insulation outside is considered, since this option is more acceptable and less labor-intensive.

Thanks to the preliminary calculations and the purchase of all the material, we can carry out the work on the insulation of the basement immediately and efficiently, so that you do not spend money on reworking or finishing work.

Types of insulation

To be sure of the final result, it is important to choose the right insulation, the range of which is increasing annually. If we talk about the insulation of the basement, here it is necessary to highlight a few basic options:

- foam;

- polystyrene foam;

- soil;

- expanded clay.

Each of the listed materials has its own advantages and features, the principle of installation.

When selecting the material and technology for warming the basement of the house, it is necessary to build on the planned budget, terrain, climate features and other nuances.

Preparatory work

Before proceeding to the insulation of the basement, you must carefully prepare. In addition to purchasing the selected material and selecting the necessary tools and fasteners, it is important to prepare the surface. If you do not know how to properly perform all the steps, then you should familiarize yourself with three main points that will be sufficient for successful work.

At the first stage it is necessary to go deeper, that is, to prepare a trench up to half a meter wide (depth is individual). The second stage involves the complete cleaning of the wall from the ground, debris and even dust. At the third stage, the wall must be protected from moisture, for this purpose waterproofing is done (for example, with bitumen mastic).

If there are obvious irregularities on the wall, they must be fixed before the start of the insulation. Waterproofing is applied in two layers, while the first must be completely dry before it is applied to the second.

The procedure of warming with soil

This method is one of the most common and affordable, since it requires minimal time, effort and material. That is how our ancestors warmed their homes outside. It was necessary to pour sand or soil into the prepared trench, but at the same time its height should reach the floor itself. Among the advantages of this technology are the following:

- a layer of waterproofing is fixed;

- accessibility;

- speed of work.

It should be noted that the soil and sand as a heat insulator are ineffective, so this option is used very rarely.

When choosing this method of insulation, it is necessary to take into account that not only the basement will be underground, but also the basement, if there is one.

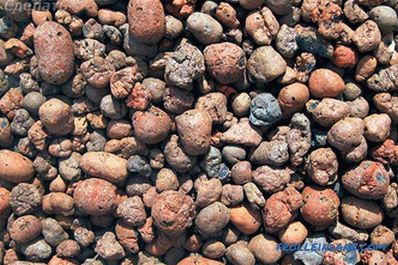

Expanded clay

Due to its porosity, expanded clay is several times more effective insulation than sand, and since its cost is also low, It is widely used. Even a small layer of expanded clay is enough for insulation, since the thermal insulation properties of the material are very high.

The prepared clay should be poured into the formwork, if we are talking about the insulation of the basement during the construction process. If the insulation occurs after the completion of construction work, the material is poured into the prepared trench. You should not mix clay with concrete, as this mixture will not give the desired result.

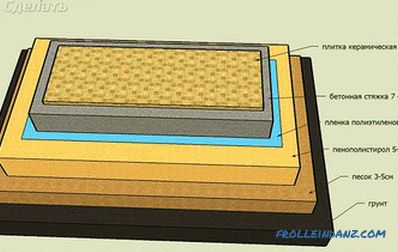

Claydite is often used for floor insulation, but in this case it is necessary to lay a layer of mineral wool and a waterproofing film on top, since the material is quite fragile.

Tiled insulation

To date, the most common materials for insulation of the socle are foam and expanded polystyrene, they vary in thickness, density and functionality.To insulate the basement with polystyrene foam, it is necessary to purchase a special adhesive solution, as well as to perform finishing work to protect the material from the effects of atmospheric phenomena.

The prepared adhesive mixture is applied to a sheet of foam, and then fixed on the wall. For greater reliability, experts recommend the use of plastic new settlers, a wide cap of which reliably fix the insulation. A plastic dowel is driven into its interior.

From the inside of the house

For the insulation of the basement from the inside of the house, you cannot use the same materials that are used for walls - polystyrene foam and polystyrene foam, as they are vapor proof. The best option for insulation would be mineral or basalt wool. In both the first and second cases, it is necessary to install an additional wall (snag) from an aluminum profile and sheets of drywall. The resulting space is filled with cotton, and the top is sheathed with plasterboard.

A rather important issue in the process of insulating the plinth inside the house is waterproofing, because without it any insulation will constantly get wet, which will lead to its rotting, mold and permanent dampness in the room. The ideal solution would be wall coating with bitumen mastic in two layers, which will reliably protect against moisture.

If it is not possible to purchase bitumen mastic, then modern dry waterproofing mixtures can be used, with which roll and abrasive materials should go together.

Useful tips from specialists

In order for the basement insulation procedure to be as effective as possible, all work should be carried out at a temperature not lower than + 5 ° C. Therefore Such works are carried out from the middle of spring until the beginning of autumn. If to carry out plaster at a subzero temperature, then the layer, most likely, will undergo a freezing and will not keep.

Before proceeding to work on the insulation of the basement, it is necessary to get rid of all types of deformations: cracks, crevices, holes, mounds and irregularities. Any kind of plaster or modern mortars will cope with this task: gypsum or sand-cement.

When choosing mineral wool, special plates should be used, which are fixed with adhesive solutions. In this case, the glue is applied to the insulation and to the wall of the basement.

Holes are made in any heater for communication in designated areas. This procedure will save time.

At each stage of the basement heat insulation, it is necessary to constantly monitor the flatness of the resulting surface. To do this, use a wooden rail or building level.

Regardless of the choice of material for warming the basement of a private house, the final works are finishing. Finishing reliably protects the material from mechanical impact, as well as the effects of precipitation.

We recommend reading:

- how to sheathe a house with insulation siding with your own hands;

- a visor over a polycarbonate porch with your own hands;

- boilers for working out do it yourself (drawings).

Video

You can learn how to insulate the basement of the house with polystyrene foam from the video: