The installation technique of a special profiled sheet used to cover roofs is relatively simple. To master it, it is quite enough to become familiar with some features of the material used, as well as with the basic rules for handling it.

Before you cover the roof with a metal profile with your own hands, you need to carry out a number of preparatory operations of the following nature:

- determine the angle of inclination of the future roof;

- choose the correct profile sheet brand blanks for the selected angle of inclination;

- to prepare the fixture corresponding to the selected material.

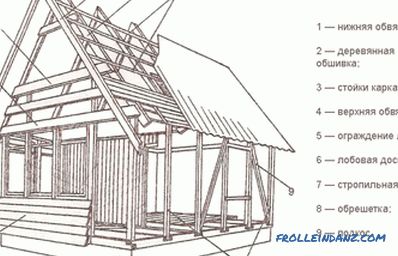

Complicated roofing made of corrugated

Complicated roofing made of corrugated

The complexity of installation work increases significantly in the case of construction of roofs of complex configuration.

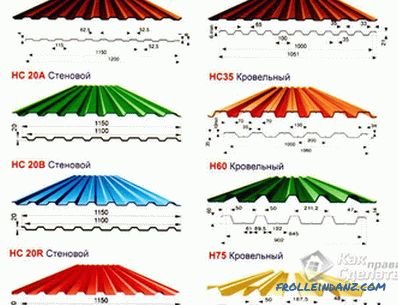

Types and brands of sheet material

At the initial stage of the preparatory work, you need to choose the type of profile sheet that is suitable for your conditions, which can have the following designs:

- Material brand "C", which is a sheet of sinusoidal (trapezoidal) profile with a wave height of 8 to 44 mm, which is usually used for the construction of light roofs or as a decorative wall covering.

- “NS” brand sheets with a fixed wave height of 35 or 44 mm, used for arranging typical roofing coatings.

- Sheet material of “H” grade with a wavy profile height from 57 to 114 mm, reinforced with stiffening ribs, which allows using it for closing roof roofs.

Roofing marks

Roofing marks

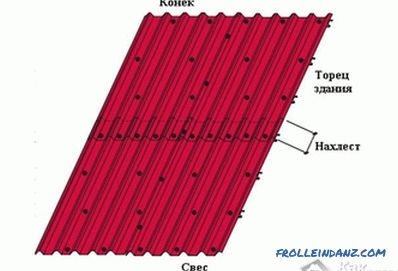

Before installing the roof covering, you should be familiar with how to properly choose the amount of overlap between adjacent sheets, which depends on the angle of inclination of the roof itself. In this case, the following relationships are true:

- when the slope angle is within 12-15 degrees, the overlap should be at least 20 cm;

- when the roof base is inclined at 15-30 degrees, this indicator can be reduced to values of 15-20 cm;

- in the case of an angle of more than 30 degrees, the overlap is selected in the range from 10 to 15 cm;

- with base angles less than 12 degrees mandatory sealing of the horizontal and vertical seams which are formed in places of overlappings. As a rule, for these purposes, conventional silicone sealant is used.

Preparatory events

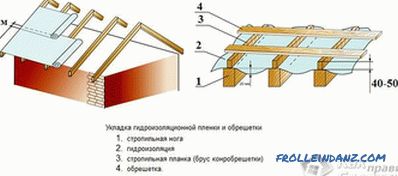

Waterproofing of the roof

Waterproofing of the roof

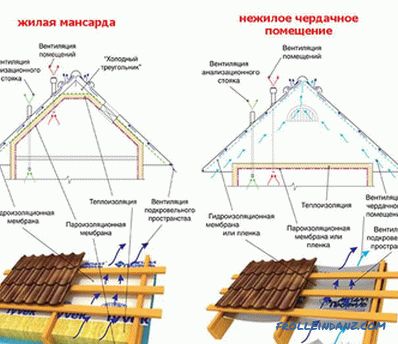

Before closing the roof with a metal profile it will be necessary to worry about the arrangement of waterproofing that protects wooden elements of the structure and insulation from the damaging effects of moisture. Waterproofing, which is usually used as a thick polyethylene film, is attached directly between the rafters with small building clips. A small overlap (about 15 cm) is made at the junction points of adjacent strips of film.

Special attention should be paid to the fact that the protective waterproofing film should be stretched with a slight slack (about 2 cm), and between it and the insulation material there should be a small gap of about 2-3 mm.

Special ventilation rails are mounted on top of the waterproofing layer, creating conditions for air circulation in free spaces under the crate and excluding the possibility of accumulation of unwanted moist fumes in this place.

Preparing the lathing

For the installation of metal profile blanks, a special lathing should be used that provides the required strength of the roof structure and withstands its breaking or bending under the influence of wind loads or under heavy snowfall.

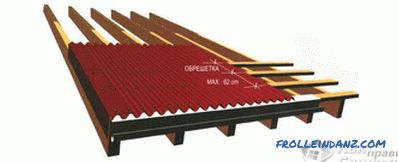

Roof pattern made of corrugated

Roof pattern made of corrugated

Manufacturers of roofing metal products indicate the main parameters and the procedure for arranging the battens for them in the instructions attached to the product. That is why before starting work it is recommended to carefully read all the instructions on how to use the purchased material.

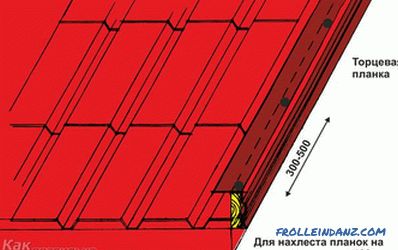

Fastening the end strips

Fastening the end strips

After the installation of the batten is completed, a special end plate is nailed onto its ramp section, width which should correspond to the height of the selected roof profile.

Thus, the overall composition of the roof covering, the final layer of which is the metal profile itself, usually looks like this:

- the inner facing layer, for example, made of drywall;

- ceiling slats used as internal lathing;

- vapor barrier protective film;

- insulation boards laid in the niches between the truss legs;

- waterproofing sheeting, excluding the possibility moisture accumulations in the area of the insulation;

- special first ventilation gap

- outer lathing

- self coating (metal profile).

Roof cake made of corrugated

Roof cake made of corrugated

Installation procedure

Rules for the installation of corrugated

Rules for the installation of corrugated

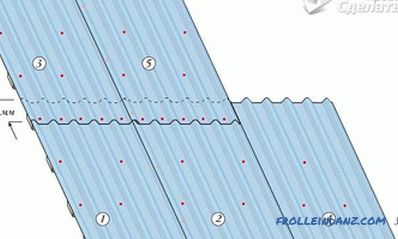

Laying roofing sheets with an appropriate angle of overlap should be carried out starting from the bottom corner of the blood. It is necessary to observe the following sequence of installation:

- the first sheet is located on the roof so that its lower cut protrudes beyond the overhang by 3-4 cm;

- then this sheet is baited with using special screws with rubber seals, screwed into pre-prepared holes located at the bottom of the wave;

- , with each subsequent sheet stacked overlapped, aligned with the edge of the previous one, and then baited;

- after the formation of a series of 3-4 sheet blanks last fix finally, on the crate;

- the second and all subsequent rows of the cover are mounted similarly (taking into account the overlap with the previous row).

Fasteners

Fasteners

To the crate, sheets are attached through each second wave.

In the course of work, it should always be remembered that it is allowed to move only along finally fixed workpieces. In this case, the feet should be placed in the deepening of the waves, based on the elements of the sheathing.

The amount of overlap is important

The amount of overlap is important

Video

About the features of the installation of flooring see the video below: