Constantly varying temperature and pressure in the plumbing system can create problems for devices that require stability to function. Uninterrupted water supply may also be affected.

Diaphragm tanks are used to minimize the effect of fluid head on devices.

These designs are different not only in size, but also in operational properties, so before choosing a membrane tank you need to know all its varieties and functions. How to choose a membrane tank and not make a mistake, we will tell in this article.

Principle of operation

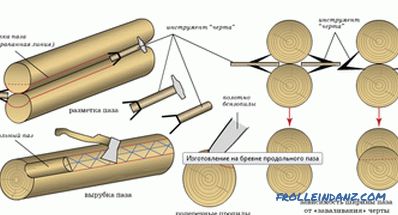

Diagram of a membrane tank

Diagram of a membrane tank

With the help of the diaphragm all tanks are separated in half. In the first part of the product is air compressed by a certain pressure. In the second half, coolant will flow after expansion under the action of temperatures. Air cushion creates high pressure when liquid enters the product.

When the coolant is cooled, returning to itself the initial volume, the excess volume returns from the membrane tank to the pressure of the air cushion. Thus, the level of the coolant always remains stable, do not let the system fail.

Varieties

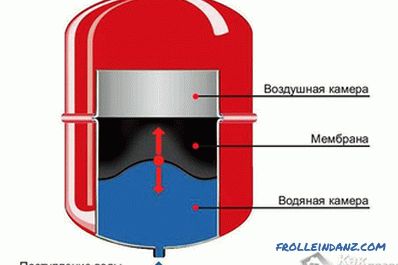

Diaphragm tanks of different sizes

Diaphragm tanks of different sizes

For the manufacture of membrane tanks use the usual and stainless steel. Volumes of these products range from 25 liters to 50. Membranes can be replaceable or non-replaceable. You can calculate the required volume, knowing the length of the water mains.

Replaceable membranes

Flanged tank

Flanged tank

Replaceable membranes are used in flange tanks.

Diaphragm tanks are vertical or horizontal.

It is interesting that the coolant, getting into such a product, is located in the central part, not in contact with the walls. Since the contact of the liquid with the inside of the product does not occur, there is no need for anti-corrosion coating. The membrane of the same technology can be changed through the flange, which is mounted on just a few fasteners.

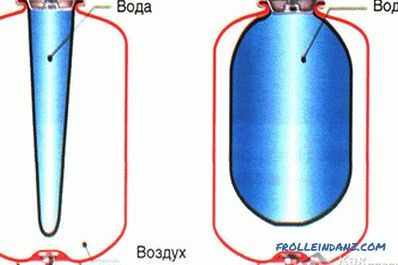

Non-replaceable membranes in tanks

A tank with a membrane

A tank with a membrane

Such a membrane is fixed all perimeter. The inner side of the wall is treated with epoxy paint to prevent corrosive processes. When the membrane is in the initial position, it is pressed very tightly against the walls by the air inside it. The apparent lack of a product is the impossibility of changing the membrane, but with careful treatment it will last a long time.

Open or closed?

Open tank

Open tank

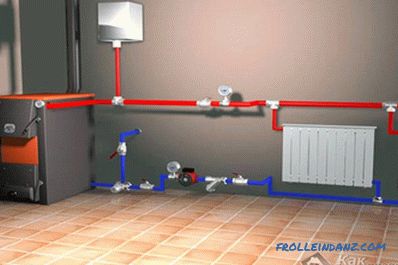

Not so long ago, open tanks provided the heating system to the full, but they had many flaws.

- As the system is open, air would enter it, which could interfere with the circulation.

- Loud noises in pumps and piping accompanied the work of such products.

- The coolant could evaporate.

- The open system needed to be installed only in the upper points, which helped to get rid of interruptions in its work.

In closed products of this kind, these defects are eliminated. Largely due to the fact that the coolant is not in contact with the environment.

Let's see what needs to be considered when calculating and how to choose a membrane tank, based on our knowledge.

Membrane

The membrane is the main element on which the performance of the product depends, and when choosing it, it is based on the purpose of the system. Tanks that provide high-quality work of heating and water supply are similar in appearance, therefore some sellers confuse them, offering not what they need.

The main criterion when choosing a membrane is resistance to temperatures and duration of operation. In the heating system of private houses, the heating of the working fluid is slow, which means that a large load on the tank is not expected. Sometimes the temperature of the liquid can reach 90 degrees, so you need to choose a product with high wear resistance. It is also important elasticity of the material.

Operating parameters

Tank parameters

Tank parameters

You will receive information on the selected tank from performance temperature and allowable pressure. According to the manufacturers, modern closed-end products withstand up to 110 degrees, while the pressure - 8-10 bar.

When the coolant heats up by 10 degrees, its volume increases by 0.3%. That is, when the fluid is heated to 70 degrees, its volume will increase to 103%. The working volume you need can be calculated using the formula that each vendor should have.

Membrane tanks allow you to get rid of problems in the future. The use of such products reduces the number of breakdowns and helps to avoid frequent repairs. Choosing a quality tank, you will get rid of the shortcomings of the heating and water supply systems.

Video

The video tells how to choose a membrane tank (hydroaccumulator).