Recently, a lot of different building materials with attractive properties have appeared. At the same time, another tendency manifested itself - the growth of developers' interest in natural components. One of the elements of environmentally friendly construction from old times is the tree, which was actively used by our ancestors.

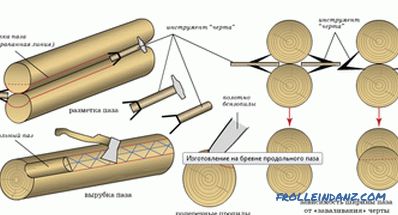

Scheme of preparation of logs for building a log house.

The modern man has already forgotten how to put a log house with his own hands. Nevertheless, in this process, nothing is impossible for someone who has hardworking hands and is able to master not too complicated technologies. And the opportunity to save our own money in our time is also not at all superfluous.

What is interesting and useful about a wooden blockhouse?

A building is a building structure, which consists of logs laid horizontally on top of each other. They form the walls of the building and connect in the corners with one of two types of dressing - with the remainder (several logs protrude beyond the corner) or without residue (without a projection). Since both types of wall joints have almost the same degree of strength, the choice of a specific option depends entirely on the aesthetic wishes of the customer.

The advantages of log cabin architecture include natural purity, attractive appearance, hinting at historical and ethnic motives, as well as cheapness compared with some types of modern construction.

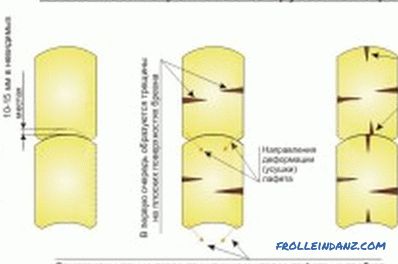

The scheme for assembling a log from a mast.

This circumstance is of particular importance in those areas where there is a fairly complex geology. In such areas, you can safely put a log cabin on a relatively uncomplicated and light foundation. In addition, wood is a convenient material for processing, which affects the quality of construction.

Both coniferous and deciduous species of wood are used as a source material for logging for log houses. As a rule, the lowest row of building logs, which is called a covering crown, is made of larch or oak. When choosing a coniferous variant of the walls, pine looks more preferable than in other conifers, it has greater strength and a relatively small amount of resin produced.

Materials and tools needed to set a log

Tools needed for work: chisel, hammer, building level, drill with a set of drills, handsaw on the tree.

For a comfortable and productive construction of a wooden house you will need:

- dried logs;

- bitumen;

- felt stock;

- lifting device;

- carpentry ax;

- chainsaw;

- wood saw;

- two-handed saw;

- drill with a set of drills;

- chisel;

- hammer;

- building level;

- metal brackets and wooden dowels (pins);

- measuring and marking devices (angle, roulette, ruler, pencils, crayons).

The procedure for assembling a wooden frame is

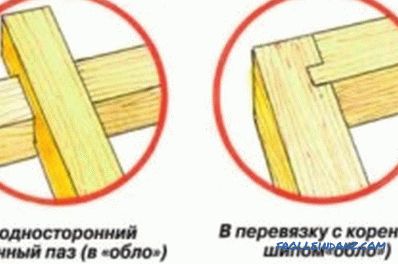

Corner joints of a timber box.

The preparatory stage consists in the selection of logs of suitable diameter, length and quality. It should be borne in mind that for areas with a cold climate, the best option would be billets with a diameter of 26 cm or more, while for temperate or warm climatic zones, a log diameter of 22-24 cm is sufficient.

For laying in the crowns of the future wooden building are selected smooth logs, devoid of significant mechanical defects, without traces of rot and signs of damage by parasites or insects. The bark from such blanks necessarily removed.

The logs themselves are cut according to the construction project of the facility, with each log remaining approximately 80-100 cm longer than the planned size of the wall. If there are not enough suitable logs along the length, you can use short logs, connecting them at the ends lock "groove comb".

The first, folding, crown of solid wood, trimmed from the bottom, is laid on the already prepared foundation, built of brick masonry or monolithic concrete. We must not forget along the entire perimeter between the foundation and the logs of the first row to lay boards 150 mm wide and at least 50 mm thick, impregnated with bitumen. In the future, this gasket will serve as a reliable waterproofing protection of the house against ground moisture.

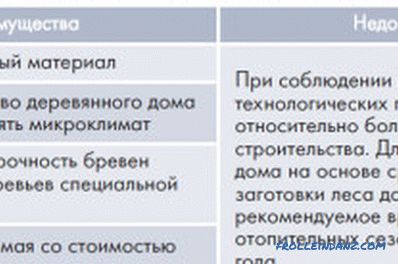

Advantages and disadvantages of a log house.

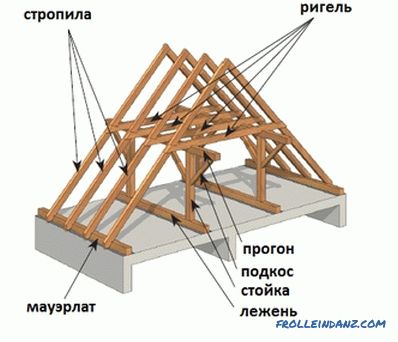

Then, the following rows of logs are mounted on the basic crown with the constant observance (by level) of the strict vertical angle and horizontal position of each row. Since all the logs objectively narrow from butt to the top, they should be stacked so that the top of the lower log is joined to the upper butt. In this case, the walls will grow evenly, without sharp distortions in height.

For a stable tight fit of the rows to each other in each subsequent (upper) log along its entire length, a groove of a semicircular cross-section of an arbitrary size is chosen. This groove top log fits on the bottom. That side of the workpiece, which will be turned inside the premises, is leveled. If there are internal partitions in the house, then the logs intended for this will be aligned on both sides.

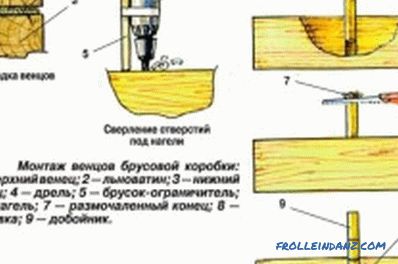

The fastening of the crowns (rows) among themselves is carried out with the help of dowels, which are made of cylindrical blanks with a diameter of at least 25 mm. Their landing is carried out in holes of the appropriate size, drilled vertically in logs in a staggered manner at a distance of 2 m from each other.

At the same time, the depth of the holes should ensure that the nagel protrudes from the wood by at least 5 cm. In such a case, the nage could prevent undesirable movement towards the upper log during its shrinkage.

As mentioned above, ligation of external walls in the corners of the house are performed both with a protrusion beyond the edge of the wall, and without a protrusion. The easiest method of dressing - through the end of the tongue. However, there are other types of dressings - "bowl", "paw", "in oblo".

Openings for windows and doors can be made with each new row, but the preferred method is to cut them out after the final assembly of solid walls. In the first case, it is difficult to withstand exactly the dimensions and levels of the project. In the second case, it is possible to avoid unnecessary distortions of the whole structure and ultimately create a uniform load on the foundation.

It should also be observed that there is a gap of 4-5 cm between the upper edge of the door (window) duct and the upper overlap of the opening in case of a possible shrinkage of the building.

As the logs are stacked or after the walls have been laid in a log house, insulating seams are made. For this purpose, felt is laid between the logs. Caulk slots tow, moss, hemp. These or other suitable materials are carefully rammed into the grooves, closing the slightest gap.

At the final stage, all hardwood floors must be covered with a layer of waterproofing material. After that, the log house for half a year is left to settle for final drying and shrinkage.

Some useful tips for assembling a log house

Assembling the rims of a log box.

In order to qualitatively make a log house with your own hands, it is recommended to remember the following important details:

- The best option for blanks are logs cut in winter. Such wood, especially if it is cut shortly before construction, contains a minimum of moisture.

- Increase the service life of the base crown in a log house can be increased in size roofing overhangs, which extend far beyond the boundaries of the log house, and the treatment of the lower row with special chemicals against destructive microorganisms.

- In order to protect against fire in places where it is supposed to install a stove, fireplace or chimney later, it is recommended to soak the wood with fire retardants.

- To facilitate the construction process, the blockhouse can be erected in parts. Each of the parts, which is called perekladki, collected on the ground height to the height of a person without a final bond. Then the reassembly is disassembled and re-laid, but already on the main log house.

The described rules and recommendations should help those who want to build their own home from the cleanest and most attractive building material.

Didn't find the answer in the article? More information on the topic:

-

What to glue parquet with your own hands

What to glue parquet? You can use different glue, its features depend on what kind of parquet is planned to glue. The first step is plywood, which should be well polished.

-

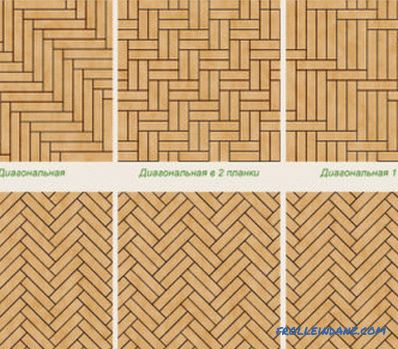

Nuances of flooring laying technology

Will consider the technology of laying the floorboard, the most necessary tools and materials. Thanks to this technology, the floors will always be smooth and durable.