How to make a barbecue from a brick with your own hands? With some skills and with the right tools at hand, you can easily cope with this task! We present you another brick barbecue construction project. This time - with a large bonfire bowl and with a smokehouse on the right side (the place for grilling is about 110 cm in length and 75 cm in depth; the smokehouse is 75 cm in depth, 70 in width and 75 in height).

We advise you to follow our example and pick up the tools. This material will help you in your work, in which you will learn how to make a barbecue from a brick with your own hands, and the diagrams, drawings and photos accompanying it will make the presentation more understandable. You will no doubt enjoy building a roasting pan and cooking food on it.

Step 1: Pouring a concrete platform is a good reason for building a new barbecue!

Gathering to pour concrete over the site to build a patio, I thought, why would not at the same time build a new barbecue out of bricks. I set to work and installed several pieces of reinforcement at the site of the planned construction of the brazier.

Step 2: Fill the concrete platform

Despite the fact that I checked and rechecked the correctness of the location of the reinforcement several times, I was still a little nervous. However, it is already too late!

Step 3: The next day after pouring

Concrete has not yet seized. I can only look from the side. I want to make sure once again that the gain is done in the right place.

Step 4: First row of masonry

I laid the first row of 10 cm concrete blocks, trying to place them exactly both vertically and horizontally (as far as This, of course, is possible).

Step 5: Second row

When the second row of masonry was almost finished, my son decided to contribute to the project. We came up with a form to support the bricks, which was useful to us to create a jumper. I realized our idea by making a narrow, long box of plywood. Subsequently, we placed vertical pieces of reinforcement there and filled the mold with concrete, making sure that there were no air bubbles inside.

Step 6: Third row of masonry

The jumper was in order. She served as the beginning of the third row of masonry.

Note: I now filled all the locations of reinforcement in every second row of the masonry with masonry mortar.

Step 7: Fourth row

Laying the fourth row, I still tried to make sure that the walls were even in all three directions.

Step 8: Construction of the smokehouse

The following two stacked rows of blocks formed the walls of the smokehouse. As before, the cavities at the points of passage of the reinforcement in each second row were filled with masonry mortar. When the refractory bricks are laid, you will need to make another partition in the form of a solid horizontal block.

Step 9: Facing with refractory bricks

I bought a standard-sized refractory brick and used it to create a bonfire floor. The 3-cm-thick refractory brick acquired at the same time went to the cladding of its walls.

Note: for laying refractory bricks, I used a mixture of 36 kg of pre-prepared cement mortar and 1. 4 kg of refractory clay.

At the same time, I was concerned about the creation of a smokehouse opening system. Installed a strong rod with a diameter of 1. 3 cm, the end of which sticks out from the front wall. Then he welded a steel plate to the rod, which will serve as a smoke damper.

Step 10: The lintel above the door leading to the bonfire bowl

The plywood shape came in handy again, between the walls of which I clamped the refractory bricks and fixed the reinforcement, and laid a wire mesh on the bottom. Filled with concrete cement, waited for it to dry, and the partition is ready. Easy and simple!

Step 11: Facing with red brick

I have a great mood - today I managed to get a good batch of red brick on the cheap.

Step 12: More bricks!

I continue to revet my building with red brick.

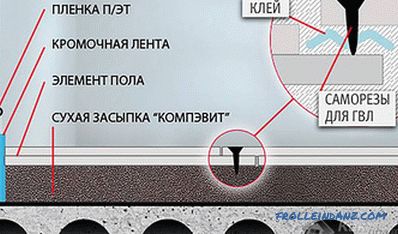

Step 13: Concrete roof of the smokehouse

Made a 5 cm concrete slab with a hole for the chimney. To reinforce it, I used wire mesh and 13 mm reinforcement. The technology, which I had already tested when creating the jumpers: made a wooden box 5 cm deep, secured the wire mesh and reinforcement inside, making sure that they were located in the center of the box, then mixed 68 kg of concrete and poured the solution into the mold. After leveling the surface of the solution, I covered the form with a piece of plastic and left it to freeze for 3 days.

Together with our son and his friend, we set the ceiling in place, not forgetting to give it a slight bias for diverting rainwater.

Step 14: Finishing up

I’ll lay some more red brick. The finish is almost finished.

Step 15: But how can we do without steel? hmm?

A visit to a hardware store and a workshop turned out to be in vain. They had everything I wanted and more.

I cut out the doors for the grill and smokehouse of the required size myself. The top covers for the grill and the chimney umbrella were made according to my order by the craftsmen from the workshop.

My friend in the neighborhood had several excellent 20 cm tiles of the right color for me. Why not use them for final finishing of the upper part of the smokehouse? You get a wonderful surface on which you can put, for example, a plate. I bought door handles and welded the hinges.

Stainless steel spring handles will not rust and become hot. Bullet hinges hinges are strong enough and keep a clean appearance. Smoke damper allows you to adjust the air flow

Step 16: Car jacks and steel drum ... Why not!

Two automotive parallelogram jacks and one steel tank with a capacity of 250 l ... To create a barbecue everything will fit. They are inexpensive, they are easy to find and do not need much modification.

For high resistance, thin metal plates are welded to the upper and lower parts of the jacks. The metal tank, sawn to the desired size, is installed on the jacks - it will be a roaster.

I can raise and lower my brazier as needed. Really useful!

Step 17: Grill grates

Square tube (1. 9 cm ), a metal grill and a 3 mm steel bar for small handles - that's all I needed to make a grill.

I decided to make the grill grid two-level and move to the right-to-left. I will be able to choose at what level and over what fire to cook food. If we build a barbecue, then so that we can cook anything there (up to hot dogs without lighting a fire).

I found on the Internet a fairly detailed description of how to design a gas torch (www.hobartwelders.com/ weldtalk / showthread. Php? T = 28224). I had to visit the workshop again ...

Step 18: Smokehouse

I welded several grills for the smokehouse and arranged them at different levels.

The springs for the handles on the doors of the smokehouse and the grill were borrowed from the saddle of the self-propelled lawn mower (therefore, the lawn mower now stands idle in the shed - it is capable of mowing the grass, but not as comfortable as before). I needed the springs for the pens to work properly. Thanks to them, the latches of curved metal plates hold the doors tightly covered, which is good news. I completed this stage of work by installing a beautiful, large and easily readable temperature sensor.

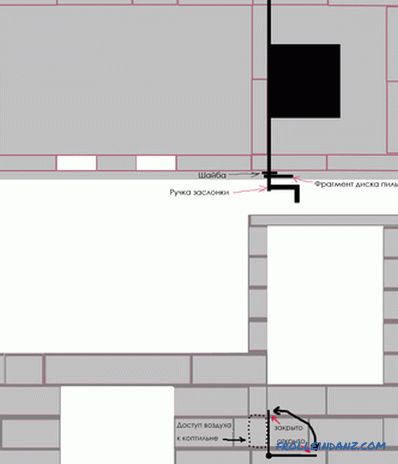

Step 19: Valve

The photographs and drawings given here illustrate the structure of the valve.

An exhaust valve (damper) is nothing more than a sheet of steel that changes its position when the handle is turned to which it is attached, and thereby regulates the flow of heat.

Step 20: Testing

I did not start a fire too much. Just tested the work of the smokehouse. Make sure it dries slowly. Keeps temperature well, warms up quickly. During testing, it turned out that the gas burner requires a small modernization.

Step 21: Barbecue Master

It was great in the summer to cook food in the open air!

I smoked a few beef brisket, pork shoulder and ribs and a myriad of chicken carcasses! All kinds of snacks - from pepper stuffed with bacon and shrimps, to grilled vegetables, fruits, corn, potatoes! Everything turns out just great!

I have two good turkeys (the weight of one of them has already passed 7 kg), which I am going to smoke at the New Year. However, the holiday is still too soon, but I want to try it now!

Smoke rushes through the flap to the smokehouse. Controlling the air intake allows you to control the temperature

Now you know how to make a barbecue with your own hands, which means you can enjoy the same amount of work and its result.

Photo and text of the user solelord, source of translation www. instructables. com / member / solelord /