The caulker is the final stage in the construction of the walls of wooden houses. This process is necessary to prevent the penetration of moisture between the elements of the log house, as the moisture that has entered leads to rotting of the logs.

After the construction of the house, the caulker is the final stage. It is necessary to prevent the ingress of moisture between the logs and acts as a heater.

Before you can caulk a house from a log, you must decide on the material with which you make the insulation. Today's manufacturer offers new materials - it is jute and lnovatin. They replaced the old ones, such as moss and tow.

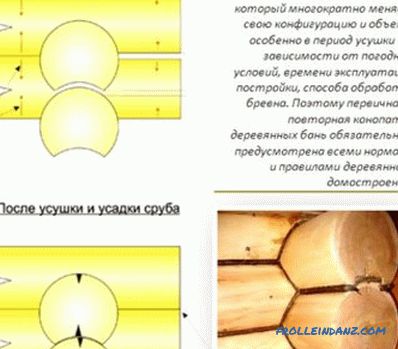

The caulking blade is made one year after the construction of the log house, regardless of whether the insulation was laid during the cutting. This time is necessary for the shrinkage of the wooden structure of the house so that the elements of the timber or log during the shrinkage take their place and take shape. A year later, it is necessary to re-caulk, as with full shrinkage additional gaps can form, which should also be caulked. Carrying out this work, pursue the following goals:

- to achieve a tight log house;

- to ensure good thermal insulation;

- to prevent wood from rotting;

- to protect material from condensation.

From whatever wooden material a house is built, the caulker is made on the same principle. The main thing - to tightly hammer material between the crowns. In some places where the wood is very dry, too large gaps are formed, in which case they are subjected to caulking with jute or hemp ropes.

Materials for cauldron at home

When selecting a material, the following requirements should be taken into account: so that the material was non-toxic, had no unpleasant odors and had a low thermal conductivity.

- it should have a low thermal conductivity;

- should not have harmful substances that can damage health;

- exclude an environment for the development of mold and fungal formations insect reproduction;

- resistant to the effects of natural factors, temperature changes and high humidity;

- should not contain unpleasant odors;

- do not lose their heat-shielding and sealing qualities for many years.

Moss. This is an environmentally friendly natural material that has the ability to absorb moisture and give it away. When using moss, wood is not subject to rotting, as it has anti-bactericidal properties. Due to its natural origin, the room is filled with a healthy and favorable atmosphere. But when working with moss there are some difficulties due to the fact that it is hard to fit. To simplify work, it is combined with tow. And even despite its minor flaws, this material is the best option.

Tow. It is also a natural material. But, unlike moss, it is a secondary product after processing flax and hemp. Possesses the same positive qualities as moss.

Lnovatin is made from flax fiber and is completely safe and environmentally friendly.

Lnovatin. It is made from pure flax fiber. It is not harmful to health, as it is environmentally friendly. Provides excellent thermal insulation. He is also inherent in the quality of absorbing water at high humidity, and at low - give it away. Thanks to these properties, wood does not give in to rotting and the formation of mold and fungus. The material has the form of tape, which is available in various thicknesses. It is laid by the method of stretching.

Jute fiber. This is the result of the processing of plants from the family of malvaceae, which grow in the territory of Central Asia, India and China. It is used in the manufacture of ropes and bags. He also enjoys great demand for caulking of wooden-log houses and logs. According to its insulating properties similar to tow, but its installation is carried out in a set.

Jute. Jute fiber is used for its manufacture; it is produced in rolls of different thickness. It is mainly used in buildings where increased thermal insulation is required. Possesses excellent heat-insulating qualities, is steady against the damp environment. The ability to not absorb moisture allows stacking directly on raw logs.

Methods and features of the caulking blade

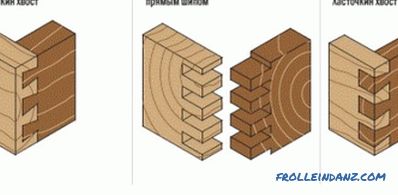

There are two ways:

- extensions;

- into the set.

Scheme of caulking methods.

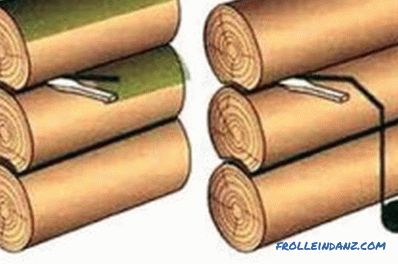

When using the caulking method, a stretch of material is woven into strands, which are subsequently wound into a ball for easy handling. From the yarns obtained, we knit loops and drive them into the gaps and cracks formed. The number of loops depends on the size of the cleft. The material for the cauldron is primarily driven into the upper edges, and then the lower ones.To give the seam a neat look, the tow is trimmed with the flattened end of the small nail puller.

A lot of attention needs to be paid to the corners, as they are caulk with special care. Filling up the walls, the ends of the tow should be released at corners by 10-15 cm.

If the caulker fits in the finished house, the height of the log house increases to 15 cm, therefore, in order not to damage the chimney, it is necessary to free from greasing solutions for the period of work.

But the laying of the material by the set method is mainly used for the second caulking. This method has found its application in compaction of large gaps and cracks. For work the roller from fiber which was prepared in advance is applied. Since the seams are the same width, the thickness of the roller must be the same. However, if in some places the gaps are larger, then the roller needs to be rolled several times to make a kind of loop. This method got its name “in set” due to the set of thickness by twisting the cord.

The material is hammered with a special caulk and a wooden mallet.

Caulking the house from a log

Every year it is necessary to inspect the house for cracks and gaps. If found, they must be caulked immediately.

The construction of the caulking of log houses differs little from the insulation of other log cabins, if you do not take into account that the gaps in log log cabins are much smaller and you need experience in your work so as not to over-heat the interlayer insulation. But with jute cauldron, special attention should be paid to the joints between the logs, as they are the weakest point.

When performing poor-quality work in the cold season in small, at first glance, crevices and corner joints, the wind will walk, which contributes to lowering the temperature in the house. Since it is almost impossible to identify these places, the caulk will have to be reworked, which will lead to waste of material and funds.

Therefore, it is necessary to caulk log houses at home with special care. If even the smallest gaps and cracks are found, they need to be hammered with the material as tightly and efficiently as possible, the caulking unit must be made both outside and inside the house.

For a log of logs, it would be most expedient to use the roller method, since, due to the rigidity of the roller, its quality and efficiency is greatly increased.

Didn't find the answer in the article? More information on the topic:

-

How should I properly caulk a bath?

Instructions on how to properly caulk a bath. A list of tools for the job, recommendations for choosing a compactor for a log house, as well as a description of two caulking methods.

-

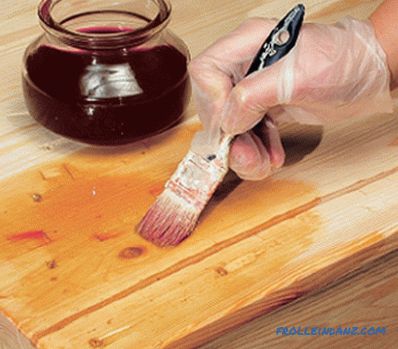

Protection and wood impregnation with waste oil

Impregnation of wood waste oil non-residential buildings. Features of processing and benefits of wood impregnation with engine oil. Preparation of a mixture of waste oil for wood impregnation.