The bending of a profile pipe is just the case when you simply cannot cope with the task without a special tool. Despite the seemingly not very strong construction, the profile tube (rectangular or square section), even with a small wall thickness, is able to withstand considerable loads without deformation.

That is why it is often used as a frame for various lightweight buildings. But if, by virtue of necessity, you have a need to give the profile pipe a curvilinear shape, you should know how to bend it correctly without damage.

Why do I need to know the characteristics of the

profile pipe, unlike a round pipe, differs in its shape, which can be of several types:

- square;

- flat-oval;

- rectangular;

- oval.

As stated in the GOST R 54157-2010 regulations, the round pipe must also be included in the list of core products. However, for the construction of greenhouses it is often used square form, since it is easier to attach a coating to it.

Today, pipe products are produced in a wide range. It varies in cross-sectional area, configuration, and wall thickness. That is, with regard to the bending of pipes is called the minimum radius of curvature. To begin with, it is necessary to determine the minimum radius of a flat rounded deformation. Otherwise, the workpiece will not "survive" the bending and damage.

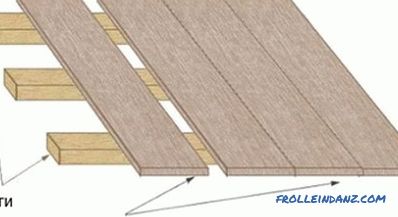

Pipe bending options

Pipe bending options

So, to determine the smallest allowable bending radius of a rectangular or square pipe, you should know profile height (h), since:

- pipe rolling with a height above 2 cm is able to withstand deformation-free losses in a section of 3.5 * h and more;

- pipe rolling up to 2 cm capable of withstanding lossless deformation in the area of length 2.5 * h and more.

Based on these limits, you can begin to design the manufacturing process from the profile pipe shelves, racks, frames for air vents, windows and doors, as well as other products. Also some adjustments are made by wall thickness.

If the wall thickness of a wide pipe is less than 2 mm, then it is generally not recommended to bend it. In this case, it is preferable to use welding.

If you decide to make a greenhouse from ordinary low carbon and carbon steel alloys, then they tend to slightly "spring up", i.e. return to their original position. Therefore, before installation, each arched arc will need to be rechecked and, if necessary, bend in a pattern.

Bending methods

Bending of shaped pipes

Bending of shaped pipes

The shaped pipe can be bent either manually (using a manual pipe bender), or using a special machine. You can choose the method based on the following main points:

- if you need to bend a small number of shaped tubes (from 1 to 5), then make it easier to manually;

- for large section sizes pipes and a considerable wall thickness you will have to use a profile-bending machine;

- a small radius of curvature can be performed either manually or using a machine.

If you do not consider yourself a person with considerable physical strength even when using a long lever to strengthen it, then you better not consider the option with a manual tube bender.

In addition, if you are not going to bend pipes permanently, then it will be financially unprofitable to buy any special tool for this purpose. As a way out of this situation, you can:

- ask for help from the nearest workshop that does this kind of work;

- make a machine for bending the profile pipes independently of scrap materials;

- use the method of bending pipes with the "grinder" and welding.

Pipe bending for the greenhouse

Here we describe 2 methods of bending: heating and cold method.

Heating

Before you start to deform the material by the method of heating, fill its cavity with sand. This will significantly increase the quality of processing, for example, the fold will be even.

Be sure to use canvas gloves for work.

So, the work process is as follows:

- From the wooden bar, make 2 pyramidal plugs. Their length should be greater than 10 times the base width. As for the area of the base of the plug, it should be 2 times the opening of a square or rectangular pipe.

- Next try on the plugs on the pipe. At one of them it is necessary to make grooves so that gases can escape from the pipe during the heating process.

- Immediately before the bending process, the workpiece should be burned.

- Now you need to fill the inside of the pipe with medium grain sand.In its composition should be completely excluded pebbles and gravel. To do this, sift all the sand. If there are large fractions in the sand, then they can contribute to the formation of irregular bending relief. For this reason, sand should be sifted through a sieve with 0.7 mm cells. If dust particles remain, then when the pipe is heated, they will be sintered inside.

- After cleaning the sand, calcine the whole mass at 150 ° C.

- After that, hammer one end of the pipe with a plug with no channels for venting. Place a funnel on the other side of the pipe and pour sand over the portions. Periodically tap the walls of the pipe so that the filler can be well compacted. If the sound of a wooden mallet is empty, it means that the pipe is well filled.

Bent profile tube

Bent profile tube

- Close the tube with a stopper.

- The place to bend should be marked with chalk.

- Now clamp the pipe with a template in a vice. If the pipe has a weld, then place it on the side. Stretching along the seam is not recommended.

- You heat the marked part red hot, and then carefully give the desired shape to the pipe. It is necessary to bend in one step with progressive movements.

- When the workpiece has cooled, compare it with the template. If everything is the same and you do not need to repeat the procedure, you can burn out the plugs and pour out the sand.

In this work it is impossible to fuss and hurry. Excess movement can distort the workpiece. Moreover, it is important to observe safety precautions, because you will have to work at high temperatures.

Heating the pipes several times is not worth it. Under the influence of a temperature shock, the material simply loses its strength; worst of all, it can burst at its next glow up to 800 ° C. Therefore, everything should be done from the first time. In this case, you will be able to make the necessary blanks for the construction of the greenhouse.

Cold method

It is possible to deform the pipe without resorting to heating. The cold folding process can be performed with or without a filler. For example, if the material has a profile height of up to 1 cm, then filler is not needed. If the pipe is thick, it is necessary to fill it with sand. Can also be filled with rosin.

A good alternative is the spring, which is installed directly on the bend section. At the expense of the spring, the material at the bend points will be protected from an abrupt change in the profile section. This article discusses several techniques for how to bend a profile pipe with a cold method.

Without pipe bender

Without using pipe bender

Without using pipe bender

As already mentioned, you can use a spring , and also complete with a blowtorch. To do this, prepare steel wire Ø2 mm. From it you make a spring so that it can fit tightly inside the pipe. As an option, you can buy a ready-made spring designed for pipe bending.

So, the spring is inserted in the marked place and heated by a blowtorch.

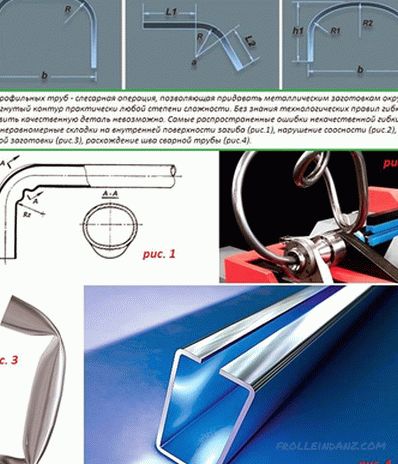

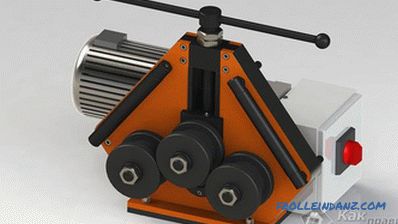

Pipe Bending Machine

Pipe Bending Machine

Pipe Bending Machine

Such a device means several types of devices that allow to bend a pipe with a different section as for greenhouses, sheds, home greenhouses and other structures where metal framework elements are used. Pipe benders are divided into two types:

- Roller. Very often it is called - profilegib. It is used to bend pipes along smooth radii. Bending is based on the principle of pipe rolling.

- Hydraulic lever arm. This technique will also allow the pipe to be bent to the desired angle. Due to the special lever, bending pipes is easy.

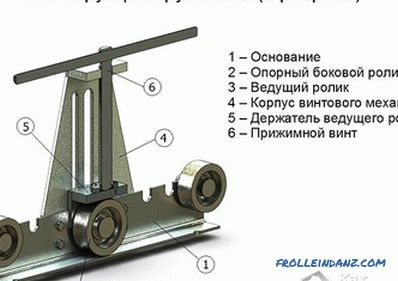

Self-made pipe bender

Self-made pipe bender

In general, using a pipe bender has several advantages, here are some of them :

- Enables less labor. When using a device with an electric drive, efforts are generally reduced to zero.

- There is no need to carry out welding work, as well as to use additional fittings.

- Thanks to the bend technology, the pipe retains its technical characteristics and prevents creases and flattening.

- Finished products get a perfectly accurate shape.

The hardest part is choosing the right machine. The choice may depend on the pipes used, namely on the material from which they are made. For example, if it is necessary to bend a copper pipe, then it is enough to use a manual pipe bender. But if you speak for the profile pipe, then for its bending it is best to use a roller tube bender.

Manual pipe bender

A manual pipe bender is a device that allows you to bend a pipe of a certain cross section by applying physical forces. The pipe bender allows you to fix the bend pipe to facilitate all the work, as well as to select the desired bend radius, focusing on the templates in its kit.

Due to the rather high physical complexity of the work on a manual pipe bender, it is usually used only to create single bent shaped tubes.

Models of domestic manual profilegibs

One of the popular profilegibs is the PG-1 and PG-2 manual machines. The first option is a fairly mobile device. Due to this, the bending process can be carried out directly at the work site. They can bend pipe size 40 * 40 mm. By design, the equipment has a frame and 3 rollers, which are fixed on it. Central, and he is the pressure roller pulls the pipe. Convenient handle allows you to carry out the process of work quite easily.

Profilegib PG2

Profilegib PG2

As for the other PG-2 model, its the design is more powerful. On this machine you can bend pipes 30 * 60 mm. If necessary, this machine can bend the pipe into a ring.

Bending Machine

Profile-Electromechanical

Profile-Electromechanical

A special machine that allows you to bend pipes without making significant efforts is called profilebom. Its only disadvantage is the high cost, so it is usually used in the work of those who have to bend pipes quite often.

Using the machine, you can get any bending radius of a profile pipe without its destruction and deformation.

Flexion occurs gradually and gradually, each time at a small bending angle, which helps prevent the appearance of corrugated sections, which are almost impossible to eliminate. The absence of jerks in the operation of this type of equipment allows the pipe surface to remain smooth, since the compression of one side and the expansion of the other occurs simultaneously and very slowly.

In order to improve the quality of the work performed, it is recommended to additionally use the method of bending the profile pipe completely filled with liquid. Hydrostatic pressure, appearing in this case, does not allow the pipe walls to deform when bent. To prevent the liquid from pouring out of the pipe, special plugs are put on its ends. It should be very careful to ensure that the pipe was filled with liquid completely, without air bubbles. In addition, the bending of such a pipe should begin strictly in the center, and not from the edges.

"Bulgarian" and welding

Try Bulgarian

Try Bulgarian

If you need to bend You can use the "grinder" and the welding machine for this purpose:

- First of all, it is necessary to accurately determine the required bending radius by making a template from wood.

- Then every 5-10 centimeters along the length of the pipe should be cut with its grinder on its three sides, always leaving the same side of the pipe intact.

- After that, the pipe must be attached to the template and gently and evenly bend to the desired shape.

- Then you just have to use the welding machine and weld all the cuts made, again giving the integrity of the pipe.

- After welding, you will have to sand the seams and cover the pipe with a protective layer of paint to prevent rust damage.

Since it is not possible to quickly bend a profile pipe using this technology, besides, skills are required to work with a grinder and a welding machine, this method is rarely used and only for individual structures.