A garage as a property is an important building that deserves special attention during construction. When carrying out the process of erecting such a room, there are often many questions about flooring. There are various finishes for this part of the building. Which one of them to prefer and how to make the floor of the boards in the garage? This issue requires careful consideration.

Floor layout in the garage.

The floor covering for the garage can be represented by a concrete or wooden base. The first option promises to be reliable and strong, even a non-professional can handle it. The cost of such coverage is low. Wood flooring is the most convenient, familiar and uncomplicated mechanism. Wood warms, which distinguishes it from concrete. Observing the necessary technical parameters, you can build a reliable and strong foundation that will please for many years.

Features of the coating

The floor of wood in the garage building is rare, since wood is afraid of temperature extremes and is flammable.

The floor of wood in the garage building is quite rare. This is due to the complexity of installation work and the properties of the tree to undergo significant changes. In addition, this natural material is highly flammable, which is very dangerous in the storage conditions in this room combustible materials. But, despite these shortcomings, a large number of consumers want to make the floor of the boards in the garage.

Before starting construction work, it is necessary to determine the choice of wood. Special attention should be paid to its quality. Boards must be moderately dried. Wet samples will lead to rapid deformation of the base. They should not be cracked. After all, the new coating will be subject to increased loads - the car is usually stored in the garage. It is worthwhile to dwell on the main conditions, without which such structures will have significant deficiencies:

- The wooden components of the building must necessarily be impregnated with special compounds, antiseptics. Such solutions will protect the surface from fire and the development of fungi and mold on their base.

- Better coverage will provide materials subjected to grinding.

- When purchasing lumber, a stock should be provided.

The floor bar in the garage must have the same dimension.

While giving preference to the plank base of the floor, it is necessary to select the size of the wood, taking into account the following features. Thus, the premise of such a plan is designed for storage of the car, and it has a lot of weight. For this reason, the thickness of the boards should be equal to 50 mm or more. The base of wood will be constructed in logs. The best option for such parts would be 100 * 100 mm.

As the necessary tools for installation, you will need:

- hammer;

- hacksaw;

- level;

- rule;

- plane;

- screwdriver;

- sandpaper and other tools.

Construction of the lag construction

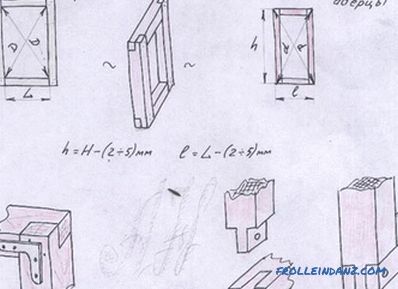

To make the floor of the boards in the garage, you need to build a foundation, a kind of lag device. It should take into account the dimensions of the foundation, the height of the basement. There are 2 ways to install lags.

Lags are placed in a transverse position relative to the walls of the room.

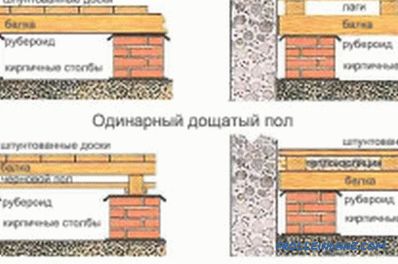

The presence of a large height of the basement part of the foundation provides the basis for positioning the lag on it. In this case, the base performs the purpose of support. Lags are placed in the transverse position relative to the walls of the room. A prerequisite would be the installation of additional supports, having the configuration of small columns or cabinets.

What materials are suitable for laying out such supports? There are several variations here. Quite good results are given by bricks and stones, construction of formwork into which the core is mounted. Moreover, the length of the lags provides the basis for the construction of a certain number of support structures. Such columns are set in advance and fixed at the edge of the foundation, in a horizontal position. Lags put in place should be leveled.

The presence of the base part of an insignificant height gives rise to the installation of a lag on the ground. Naturally, putting them on bare ground is not worth it. For this it is necessary to carry out processing. An elementary option would be to level the surface with sand and rubble. An analogue of a shchebnevy composite is expanded clay. Top poured cement-sand mortar. The resulting coating will be incredibly strong, smooth. Such a foundation will facilitate the rapid establishment of lags in place.

Possible constructions of a plank floor in the garage.

Under the base of this design it is best to lay a fabric that promotes good waterproofing of the base.In this quality, melted bitumen applied on the screed, or roofing material is well suited.

And the first option is used infrequently. Of course, this method is cheaper, but the ground under the lags will not give a strong base, and it will not be able to take on a significant weight of the structure. Even a concrete screed cannot cope with the task. Such a device will be able to serve in the garage for about 2 years. Rapid wear of a similar design is inevitable. Therefore, before laying such a foundation, you should think about its necessity.

Laying wooden planks

As soon as the logs are delivered and securely fixed, you can begin the installation of the floor covering. No one will argue that this room is not located for living. But still the quality of the coating must be given maximum attention.

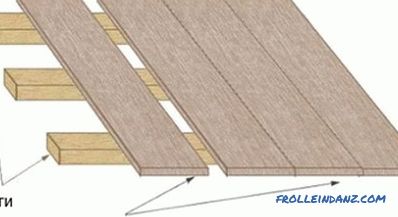

It is necessary to make a floor in a garage building, observing the same technology that is carried out in an ordinary house. The process of laying boards should be carried out taking into account the fact that they must cover the surface of the longitudinal position of the garage room.

Installation: Recommendations

The process of arranging a wooden floor usually starts from the corner of a room located at a far point.

The boards on logs need to be fixed with self-tapping screws.

The first board is placed on the lags prepared in advance. Do not forget about their parallel arrangement. The coating is fixed with screws. After that, a wooden plank of equal length is selected and fixed on the logs at a distance slightly more than the width of the original board. Then in the space between the boards the second one is laid, wedges of the same material are inserted in the gap between them.

As them you can use the remnants of defective boards. These same wedges are hammered with a hammer or mallet along the entire length of the board, one of which should be pressed against the first. The second floorboard is fixed with screws. The rail is removed, shifted to the desired distance, securely fastened. Further installation of the floor is carried out according to a similar scheme.

As is clear, the process of building a wood flooring is not at all complicated. By following these rules, you can easily make a stable base. Another important attention should be paid to the question concerning the rapid erasure of the board surface due to increased load and periodic operation of the coating. In order to avoid common problems, the outer part of the boards should be treated with linseed oil or enamel. Save on this is not worth it. The more densely the surface will be finished, the longer the coating will serve. In this way, it is possible not only to improve external indicators, but also to extend the life of the floor.

When you start laying the floor of the boards, you should be careful and attentive, it is important to have a clear plan for the main works. Such work can be carried out independently, without attraction of a labor. To ensure coverage with a special strength you need to choose the appropriate type of material.

While giving preference to one or another type of board, one should pay attention to the thickness and strength of wood. The strong and volume board will serve long. An important value is given to the fastening of the selected material. Strictly following the technology of laying and fixing on the lags will be the key to the stability of the structure. An important part of the floor will be laid waterproofing layer. Often it is made from plastic film. After all, an excess of moisture is detrimental to wood, which over time begins to rot.

Conclusion and debriefing

So we looked at the main issues concerning the installation of flooring in a garage made of natural wood. This coating can last for about 6 years. The need for such an installation, each person determines their own.

Such a foundation needs periodic maintenance. It must be painted, repaired, cleaned of dirt. However, this coating gives heat. In conditions of complete garage insulation, this option will be ideal.

Didn't find the answer in the article? More information on the topic:

-

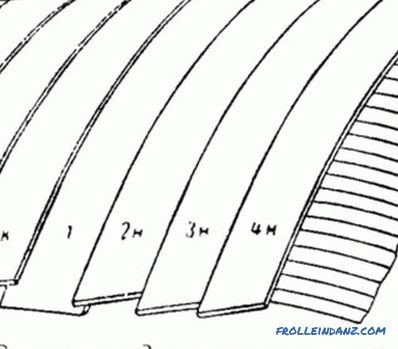

How are wood veneers made?

Information on how veneers are made. Three ways of industrial manufacture of veneer. Making veneer your own hands. Finishing veneer of various surfaces.