Nowadays pipes are used in many professional fields. They are used in construction, manufacturing, mechanical engineering and even in agriculture. In the process of performing various tasks on the arrangement of the house and the area near it, too, can not do without pipes. To shape the pipes, they should be bent. But how to do that? In the article you will learn how to bend a pipe without a pipe bender (for example, for a canopy). We suggest that you familiarize yourself with simple, but effective methods of bending the shaped pipes at home.

Methods

The methods of bending

The methods of bending

The bending of the pipe is carried out in various ways. Some men who are strong in their hands even do it with small-diameter pipes by hand. However, this technique is unreliable - the risk of pipe breakage is high. In view of this, it is better to use available materials or special equipment for these purposes, which, among other things, will facilitate bending at times.

Plane-parallel plate

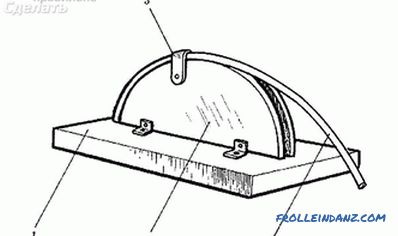

If you really need to bend the pipe, and buying special equipment in this situation is unprofitable, then you can use a curved plate with a groove for this. It can bend metal / metal-plastic pipes with a diameter of 45 mm.

In order to bend the pipe, it should be inserted into a special clamp on the plate, then clamped and bent along the groove. This technique is rather primitive, but as practice shows, it is quite effective.

Only short pipes can be bent on a plane-parallel plate.

Bending of a thin-walled steel pipe

Bending of a thin-walled steel pipe

The diagram above shows a simple plane-parallel plate, where under Number 1 is the plate, number 2 is the plate, respectively, 3 is the clamp, and 4 is the pipe to be bent. Such a device is quite possible to make yourself.

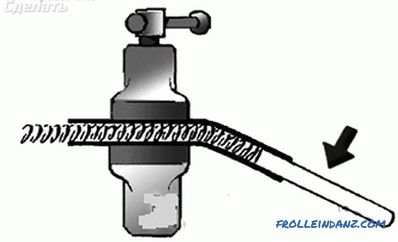

Steel spring

The pipes made of soft non-ferrous metals are thin-walled, so this is a rather malleable material. This explains the fact that bending pipes from it often leads to damage to them. In order to avoid this trouble, when bending a pipe from non-ferrous metals, a steel spring is used having an average stiffness.

The diameter of such a spring should be slightly smaller than the internal diameter of the pipe. This is due to the fact that it will need to enter into the pipe to the place of the bend. After that, the pipe can be bent, for example, on the knee or having previously secured it in a vice. The steel spring holds the walls of the pipe from non-ferrous metal, preventing them from flattening.

Before you insert the spring inside the pipe, you need to securely attach a long strong wire to it. Due to this, you can remove the spring from the pipe after completing its bending.

The Popular Method

The Popular Method

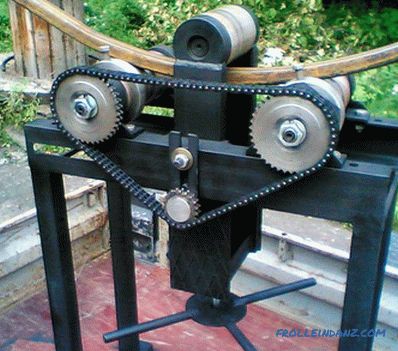

One of the popular methods is making bending device. To do this, a small pipe with a larger diameter must be welded to a long pipe of a smaller diameter. Thus, the tube to be bent is put on the fixture and its formation is carried out at the right angle.

Profile pipe

Methods for bending a profile pipe

Methods for bending a profile pipe

Before you begin bending the profile pipe, it would be nice to get acquainted with its characteristics, starting from which you can choose the method of its bending.

You can learn about the characteristics of the profile pipes, as well as the methods of its bending, in the article "Methods of bending the profile pipe".

With a grinder and welding

Bending with grinders and welding

Bending with grinders and welding

One of the methods of pipe bending involves the use of welding and grinders. The bending of the pipes in this case is performed in the following sequence:

- The first step is to calculate the radius of the pipe.

- Along the length of the section to be bent, uniform transverse cuts are performed.

- Then the pipe can be bent without any effort.

- The sawn spots should be boiled.

- Then the place of the fold should be processed by grinding the welding points.

This method allows you to bend the pipe at the desired angle.

If this article helped you, be sure to let us know by writing a comment to the article. Any questions you can ask an expert of our site.

Video

The provided video footage shows how to bend the pipe: