The construction industry is developing rapidly. Already today it is possible to build a large house with minimal cash outlay. Such a structure as a whole is not more expensive than a one-room apartment, and living conditions in it are even better.

It is not always possible to choose the right material for the upcoming construction. Many developers do not have sufficient knowledge of materials science, so they have to believe advertising. Manufacturers use this, praising their goods and not objectively criticizing competitors. Most of the controversy takes place around the new Canadian technology of building construction.

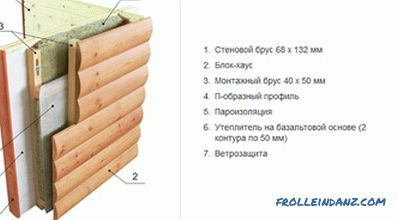

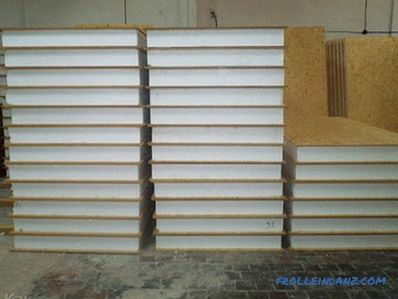

Such composite panels consist of a pair of special plates with a layer of insulation between them, which is used as polystyrene foam or foam. Developers are attracted by this quality because of their qualities as well as the speed with which houses are built from it.

Benefits

Benefits - speed of construction

Benefits - speed of construction

Factory readiness is a guarantee of future quality structure and an essential condition for reducing the time of its construction. They assemble SIP panels in the factory using modern equipment, which allows controlling the strength of the whole structure. As a result, the equipment is selected in such a way that there is no opportunity for assemblers to act independently, because this can result in marriage.

Laying

Laying walls

Laying walls

The panel hip is rather light material, therefore heavy foundation is not necessary. For our structure there will be enough pile foundation, on top of which it is necessary to lay a binding beam.

Starting boards are laid and fastened with screws with the screws, after which you can start installing sandwich panels. This material is connected according to the well-known principle groove-comb.

Tightness of the joints is achieved with the help of mounting foam, which is necessary to process the ends of each sheet of sandwich panels immediately before connecting to adjacent elements.

If you chose a strip foundation, then the assembly should be done a little differently. In this case, the fixing of the strapping board should be carried out directly to the composite panels, and not to the timber, as in the previous case.

Roof of vulture

Roof of vulture

Vertical joints are connected in the same way. With proper treatment, this method is suitable for mounting roofs and floors. As a result, we should have a solid structure without gaps through which a draft could penetrate. It is quite easy to build a house of vulture panels, and the result is a robust construction with high thermal insulation properties. Such structures do not shrink and do not crack, which is their clear advantage.

You can save money during construction on the characteristics of the material, as they allow you to stack it without special equipment. Wet technologies are not used during assembly, so the construction of houses from a vulture panel is interseasonal.

Finishing

Finishing the prefabricated house

Finishing the prefabricated house

For finishing the brick buildings would be more strength and energy than in our case. The walls of the vulture panels are smooth, so for their plasterboard plasterboard does not require a leveling frame.

Sandwich panels easily incorporate screws and nails and hold there securely, which allows the use of any materials, be it natural stone, wooden lining or ceramic tile. On the vulture panels are well kept and adhesive mixtures. If the floor in the house is made of our material, then you can lay parquet on it, tile it or lay linoleum.

Select the CIP of the panel

Select the sip of the panel

Select the sip of the panel

evaluating the quality of the materials used. For the assembly of panels required OSP-3 tile with a high level of moisture resistance. It should also have a level of formaldehyde emission E1 or lower, which is safe for health. In the middle of the panels should be self-extinguishing foam or polyurethane foam.

Disadvantages

A sandwich panel is a material that does not allow water vapor to pass, so the structure of it is more like a thermos and needs regular ventilation. The CIP panels have low sound insulation performance, although the manufacturers insist on good sound absorption by the foam.

Since the weather is unpredictable, and construction will take at least a week, it is necessary that there are drainage holes in the ceilings. It is also recommended to look at the quality of filling the edges of the panels.

House of panels

House of panels

The fire resistance of buildings made of sandwich panels is not the highest, therefore when laying communications, You should contact an independent electrician to help avoid problems. Also it is worth taking care of fire alarms in each room.Thermal sensors will not be out of place.

As a result, we found out that the CIP panel, though good material, still has its flaws. To avoid problems will help some materials that need to impose additional structure.

We recommend that you familiarize yourself with:

- drilling a well with water;

- how much does it cost to fill the foundation for a house;

- how to make a polycarbonate fence.

Video

We offer to watch the video and learn about the advantages and disadvantages of using vulture panels.