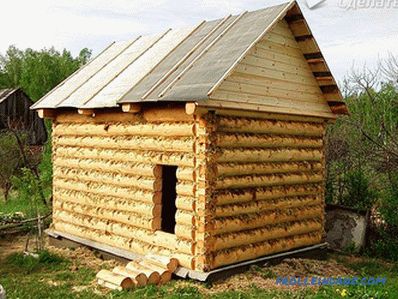

Self-installation of a gable roof is possible only if you have certain skills to work with such structures and involves increased attention to all details of construction procedures. To facilitate the implementation of the upcoming work will help you a careful study of our instructions, which describe in detail how the gable roof is made with his own hands, taking into account all the nuances of the operations performed in this process.

Roof options

Ondulin coating

Ondulin coating

To understand all the subtleties and peculiarities of the upcoming first, we will introduce you to well-known types of gable roofs with different slopes of slopes, the choice of which should take into account the following factors:

- type of roofing;

- local climatic conditions;

- the functional purpose of the structure.

The angle of inclination of the slopes of various buildings can vary in the range of values from 10 to 40 degrees and significantly affects the choice of roofing material. In accordance with this indicator, gable structures can have the following versions:

- with gentle slopes (up to 20 degrees);

- roofs with a large angle of inclination (more than 20 degrees);

- roofs with a sloping sloping line (with a variable angle of inclination).

Preparatory measures

This snow load must also be considered when designing

This snow load must also be considered when designing

In order to decide on the choice of the roof configuration that is optimal for your conditions, first of all it is necessary to take into account such an indicator as snow and wind load on it. Naturally, with a decrease in the angle of inclination of the roof, wind loads are markedly reduced; however, in this case, it becomes impossible to use the roofing space for household needs (for attic space, for example).

When choosing the form of a gable roof, it is usually assumed that the key supporting points of the truss system coincide with the lines of the location of the supporting structures of the structure itself (its upper floor, in particular). At the same time, the width of the house as well as the presence of internal load-bearing walls is taken into account.

Suspended gable roof construction

Suspended gable roof construction

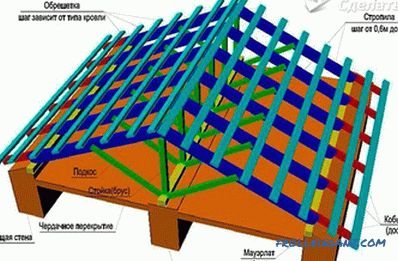

In preparing the project, the presence or absence of an attic in the future structure is taken into account, as well as the overall dimensions of the closed roof space. With a significant size of the closed area in the construction of the truss system (in addition to the transom, used as a carrier ceiling) should include additional elements - the so-called runs and racks.

It would be right to think about where the entrance to the attic will be, and if necessary to make a staircase.

When constructing a gable roof with your own hands (without an attic), it is allowed to use a system of inclined rafters attached with their upper part to the ridge girder. This run itself is supported, in turn, by special racks installed with support on the internal supporting partition.

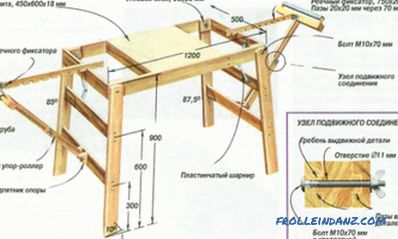

The most practical and economical option for arranging roof structures, used mainly for lightweight buildings, are hanging rafters, for arranging which, the rafter legs are connected in pairs with the help of special bolts. The latter are horizontal jumpers that provide the required stiffness of the whole structure as a whole. Each of the hanging rafters rests at its ends on the side walls of the building.

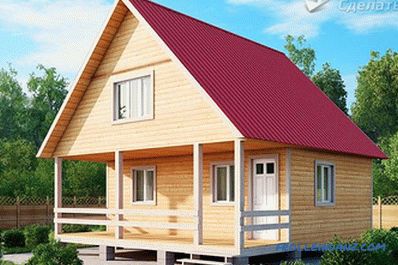

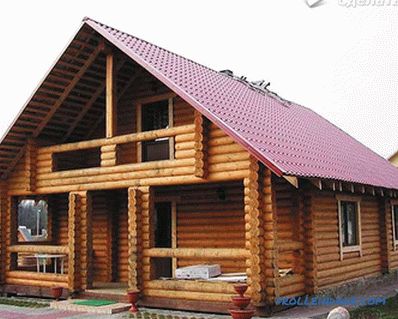

Views

Views

In case its width exceeds 6 m, you will have to increase the number of installed runs and racks. Recall that the girder is a special horizontal bar used as an additional support for rafters and mounted using special racks.

These racks are based, in turn, on the so-called rods (pre-prepared timber laid along the slope). Such a timber together with racks can serve as a frame for the walls of the planned attic space. Thus, the use of naval rafters will allow you to equip the attic or a fairly spacious attic room used for household needs.

But before you make a gable roof, you first need to worry about preparing materials for it. When calculating the volume of the required lumber, try not to overlook the fact that the weight of the truss system should not exceed the value for this construction. In this case, the section used for its arrangement of lumber, as a rule, is selected based on the size of the structure itself.

Mauerlat

Securing the Mauerlat

Securing the Mauerlat

The Mauerlat is used as the supporting base of the truss structure and ensures its reliable and stable fixing on the walls of the building.As a mauerlat, the usual timber with a cross-section of 100 * 150 mm is mainly used; it is mounted around the entire perimeter of the building and ensures uniform distribution of the load on its walls.

Fastening of a mowerlat wall in a wall can be done in one of the following ways:

- special (rolled) wire used for fixing the support bar to the wall is bricked in the brickwork;

- metal studs of the required size are bricked into the masonry (diameter not less than 12 mm);

- a special monolithic concrete beam is made along the wall, equipped with steel studs.

The studs used to securely fasten the Mauerlat are located along the perimeter of the building in increments of about 120 mm. When choosing the height of the fastener, you should consider the total thickness of the waterproofing layer and timber with pre-prepared holes. During installation, the support bar is installed on the studs and is firmly fixed with nuts, equipped with wide washers.

Arranging the truss system

The truss system

The truss system

The trusses system of a typical house contains a whole a number of parts, structurally combined into one. The main element of the gable roof is an A-shaped truss, which is a rigid structure that works on the principle of "on thrust". In the event that the frame of the house is made of timber - you should take care that its walls at the level of the ceiling beams are reinforced with special ties, excluding the possibility of their displacement under load.

On the ceiling on the side of the attic, special logs are laid (bars with a section of 150 * 150 mm), which serve as a support for the propeller racks. All repeating elements of the rafter system are made strictly according to the template, which allows to obtain an isosceles duo-pitch construction after assembly with an even distribution of weight loads.

Assembled trusses

Assembled trusses

A-truss for truss systems are assembled directly on the ground, after which the prefabricated structure rises up to the overlap prepared for the installation of the truss. In this case, the girders are installed with support on the rails, and the rafters with their lower ends are mounted on the power plate.

In passing, we note that when making a truss structure template, you can arbitrarily change the length of its constituent elements by varying the parameters of the future roof (its height, for example). Thanks to this, you can choose the best option for your conditions.

When installing rafter legs in the places of their joining with strapping, special figured cut-offs are made to ensure reliable contact and a rigid bond with the power plate. To increase the rigidity of the structure in this mount is often used special metal plates.

Gable

When preparing a construction project (that is, before building a house) you will need to carefully work out the arrangement of its gables.

Externally, the gable looks like a continuation of the wall, having a border along the line of the roof slopes. For the case of the gable roof we are considering, the gables have the shape of an isosceles triangle. The gable bases are extreme trusses, the height and verticality of which is strictly controlled.

Ridge

Ridge

The ridge girder is installed in the upper part of the gable trusses, to which the rest are attached rafters. Sewing of pediments with boards is carried out in a pre-selected direction (vertically or horizontally). Usually it is organized upon completion of the entire complex of roofing works, but it is allowed to do this simultaneously with the latter. With all the subtleties of mounting gable gables roofs you can familiarize yourself by viewing the corresponding video.

In conclusion, we note that both gables and elements of the roofing structure roofing are subject to compulsory insulation.

Photos

Video

This video shows the installation of a sloping roof with gables: