Acrylic baths in the domestic market of sanitary ware appeared relatively recently. In total, it took some 10–15 years for an acrylic bath to take its place in the neighborhood of the baths made of cast iron, which have long been familiar to our man. This is due to the large number of advantages that acrylic plumbing has, for example, less weight, low price or original form. However, as you know, the more the choice, the more difficult it is to make a choice.

In fact, when they come to the plumbing shop, sometimes their eyes diverge from the acrylic baths presented for sale, and most consumers most probably have a logical question - which acrylic bath is better to choose, because the price of plumbing is far from an indicator quality and durability. Let's try to sort out in detail all the nuances of choosing high-quality plumbing, and at the same time, let's talk about what often sales consultants are silent about.

What kind of material for the manufacture of an acrylic bath is better than

From the name of the plumber, it is clear that the acrylic bath is made of acrylic. Acryl is a component mixture of complex polymer compounds of esters and methacrylates. Speaking in simple human language, acrylic is a type of plastic, which is characterized by its strength, elasticity and smooth surface.

You can find plumbing fixtures made of the following material:

- ABS / PMMA;

- Polymethyl methacrylate.

Material - ABS / PMMA, is a two-component, consisting of acrylonetril butadiene styrene and polymethyl methacrylate. Acrylonetril butadiene styrene is a type of elastic plastic, and polymethyl methacrylate is a type of homogeneous organic plexiglass. In fact, in this material, the ABS performs the base and makes up about 90% of the total mass, and the acrylic layer itself is made of PMMA, about 5-10%. The disadvantage of an acrylic bath made of ABS / PMMA is rapid wear and a shorter service life, about 3-5 years. The thing is that although the ABS itself is a plastic, this polymer has a porous, hygroscopic structure, that is, it is able to absorb moisture to some extent, which leads to its rapid destruction. At the same time, a thin, precisely acrylic layer made of PMMA, with frequent use of plumbing equipment, is quickly exhausted.

Material - polymethyl methacrylate, as mentioned above, is - plex, plexiglas. In acrylic baths made of pure PMMA, there is no completely layer of porous ABS, and the plumbing itself is characterized by high rates of wear resistance and durability. On average, an acrylic polymethyl methacrylate bath can last 10-12 years from the time of installation.

What is the guide and how to choose an acrylic bath based on the material

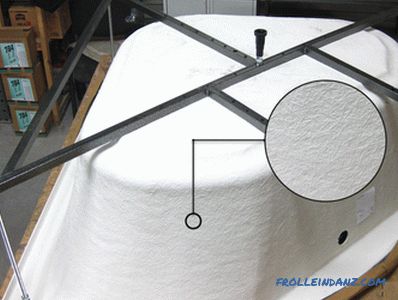

When visiting a plumbing store, of course, an intrusive salesman consultant can write a lot about the advantages of a particular acrylic bath model, however, the first thing you need to do it specifically for you - it is your own to visually estimate the number of layers of plumbing. This can be done by inspecting the edge of the side plumbing.

If you counted 3 layers, you should know that this bath is made according to the scheme: ABS + PMMA + base.

If you counted 2 layers, this bath is made of pure PMMA + reinforcing base.

Having understood which particular plumbing you are dealing with, then you need to answer yourself the question - where and for what purpose does the acrylic bath are bought. If you need to buy a bath for a country house, where, in principle, accommodation will be seasonal, and the plumbing itself will be operated from a couple of months a year, then of course it does not make sense to overpay the excess, and you can purchase a bath made in the ABS / PMMA scheme. If we are talking about buying and installing a bathroom in a city apartment or a country house where you live permanently, then there is no point in saving, and it is better to buy a bath made of pure plexus, that is, PMMA + reinforced base.

What should be the thickness of the sheet of acrylic and reinforcement

As it was written above, if you look at the end of the bathroom side, you can visually distinguish several layers in the sheet structure. In the eye, the layers in the structure of the bathroom wall are in many ways similar to the age-old rings that can be observed on the stump after cutting a tree. Since the main issue is how to choose a durable acrylic bath, the main attention should be paid to the thickness of the acrylic layer itself, that is, the face layer.

In a supermarket or plumbing store, you can find models of acrylic baths with an outer layer thickness of 2 to 6.5 mm.

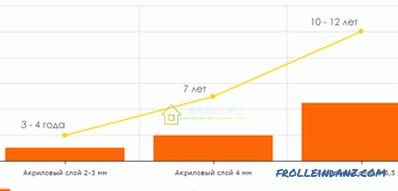

On average, the trend is this: if the acrylic layer is 2-3 mm, the bath will last about 3-4 years; acrylic layer about 4 mm - bath can last up to 7 years; acrylic layer 5-6.5 mm - bath can last 10-12 years.

In addition to the thickness of the acrylic layer itself, one should also pay attention to the general condition of the inner surface. Sometimes there are such "crafty moments" when the consultant’s salesperson starts to paint the not quite smooth surface of an acrylic bath as some kind of know-how in the world of plumbing. This is a lie. Most likely the seller or, in fact, the store, trying to get rid of the stale low-grade or even defective goods.

It is important to remember: in a high-quality acrylic bath the surface should not have any hillocks or roughness. The smoothness of the surface should be such that if you attach a human hand tightly to it, the palm should not even slide, but as if, due to the flatness of the surface, slightly stick. For example, try to hold a tight palm on the window glass, with a high-quality acrylic coating, the effect should be about the same.

Bath reinforcement methods, and which one is better

In its pure form, the acrylic bath bowl is not very durable, because acrylic is a flexible and ductile material. To give it rigidity to the outer surface of the bath sink, a reinforcing layer is applied. The reinforcing layer is applied in the factory, already on the finished, cast bowl on top of the ABS / PMMA or PMMA from the outside.

Structurally, the reinforcing layer is a glass fiber that is treated with epoxy resin.

The total number of reinforcing layers can be from 1 to 5, depending on the quality of the plumbing. In total, buying an acrylic bath, it is enough to take a good look at the end of the bathroom wall to visually assess the number of layers and the total thickness of the reinforced base.

It is important to remember the following: a high-quality acrylic bath is reinforced with a uniform layer over its entire outer surface. Many unscrupulous manufacturers, in the production of plumbing, use the following trick. Knowing that the “savvy” buyer will necessarily evaluate the thickness and layers of reinforcement on the end, in the process of applying the reinforcing layer by the manufacturers, the sides of the sides are intentionally reinforced better than the bathroom bowl itself. In order not to fall for this trick, in addition to visual inspection of the butt, it is necessary to independently lightly press on the bottom of the bowl and the bathroom wall. With high-quality reinforcement, they should not sag like plastic lining, but should maintain elasticity.

Another way that can help you choose a high-quality acrylic bath is to try putting a flashlight close to the bottom of the bath and at the same time, putting your palms together, look at the area of the same surface on the other side. If you see a very clear light from the flashlight, you know, the thickness of the bottom of this bath is smaller, the thickness of its walls and, in fact, this product is of questionable quality.

In general, three things will have to be done:

- Inspect the butt;

- Press the walls and the bottom;

- Test the walls and the bottom to the light with a flashlight or laser pointer.

Of course, here we talked about if you need to choose an acrylic bath from an unknown manufacturer, or the plumbing store itself does not cause much confidence. In the case of the purchase of an acrylic bath in a specialty store from a reputable manufacturer, you are unlikely to come across such a "hack." But it is better to check everything.

Choosing the size and shape of a bathroom

A bath is not just a sanitary hygiene item, it is also a place where you can relax, have a rest and improve your body. Yes, it has long been proven that taking baths with certain oils, herbs or mineral additives has a positive effect on overall well-being and raises the tone. For this reason, the main criterion when choosing an acrylic bath is convenience.

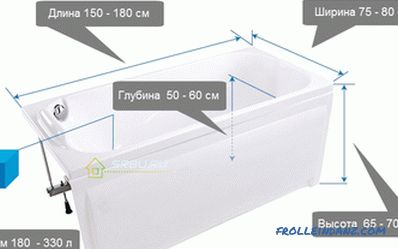

The optimal bath height is 65-70 cm from the floor level. This value is considered to be “family”, as the subject of plumbing can be used without difficulty by both adult family members and children or teenagers.

The optimal depth is 50-60 cm , calculated from the bottom plane of the bowl to the level where the overflow hole is located. In a shallower bath, the water level may not completely cover the body of the person lying in it, and in a deeper bath, the head of the person taking the bath may not be in a very comfortable upright position.

The optimal width is 75-80 cm , but this parameter also depends on the height and build of family members. For example, a full, fat person 75 cm may be small. It does not matter, because on sale it is quite easy to find an acrylic bath with a width of 100, and 120 or even more centimeters.

The optimal length is 150-180 cm , however, this figure directly depends on the specific plumbing model and the growth of family members.As for the bath model, if there is a headrest in its design, a bath of 165-170 cm is suitable for a person with a height of 180 cm. A bath is selected directly according to its height - 180 cm. Below you can see the standard dimensions of the length of the bath and the possible position of the body at a certain length.

As for the shape of the bath itself, then, conventionally, all plumbing can be divided into longitudinal and angular. Longitudinal plumbing installed headboard or one of the sides close to one of the walls of the bathroom. Corner bath is installed directly in the corner of the bathroom. At the same time, among these highlighted conventional types, there are models of acrylic baths with the most incredible and diverse design. It is senseless to advise any particular style in plumbing, as each has their own individual preferences. It should only be noted that the choice of the shape of the bath: rectangular, oval, round, angular will depend on the size and layout of the room in which they are to be installed.

Strength of construction and frame

The strength of an acrylic bath depends largely on the method of its manufacture. That is, the bath, which was manufactured using the PMMA acrylic solid cast technology, is fully capable of retaining its original shape when fully filled with water. If the bath is made of extruded two-component acrylic ABS / PMMA, then with full filling of its walls may slightly deform. This is mainly due to a thin layer of PMMA and a thick layer of flexible ABS plastic.

Regardless of the acrylic used, all baths are installed on a special welded or assembled metal frame that performs the function of the base and inhibitor of the bath against excessive deformation during full filling. The design of the metal frame - the frame, to some extent also influences the cost of the acrylic bath.

The simplest frame is a welded metal or bolted metal "crate", which will be located directly under the bottom of the bath. That is, such a frame will withstand the vertical pressure of water and the weight of a bathing person, but it will not strengthen the side walls. A more complex frame for an acrylic bath, has in its design elements that reinforce the side walls of plumbing, which in total can extend the operational life of the entire structure.

But here there is also one thing that can help determine the quality of the bath. The frame frame has points of support (racks and legs). The more such racks, the less durable is the bath itself. If the bath itself is of high quality, the frame has supports only in the corners.

Additional options for acrylic baths

The most popular and beneficial to health, is considered such an integrated option in acrylic baths like - Jacuzzi. Jacuzzi is characterized by the fact that, unlike taking a conventional bath, a hydromassage is applied to the human body, and in some cases chromotherapy is affected by ultraviolet radiation on the skin surface. Hydromassage in the jacuzzi is performed by air bubbles continuously flowing into the water through specially bronze or chrome jets built into the side walls of the bathroom.

Chromotherapy occurs due to the blue LED backlight with prismatic reflectors embedded in the side walls of the plumbing. Simply put, there is an effect on the skin of the blue lamp, which stimulates blood circulation and has anti-inflammatory action. If you just need to figure out the hydromassage, for example, by estimating the number of nozzles, modes and control method, then with chromotherapy it is much more difficult. Here the maximum effect depends on the power of the lamps and the correct reflectors chosen and focused by the manufacturers.

Advice for those who are thinking about how to choose the right acrylic bath with integrated Jacuzzi elements: sanitary ware with high-quality hydromassage and chromotherapy can only be from well-known serious manufacturers. And how to choose an acrylic bath by manufacturers will be described below.

In addition to the above hydromassage or chromotherapy, a modern acrylic bath can please its owner with various useful options. For example, models of plumbing, in which a special shelf is provided for accommodating a laptop or in which a plasma TV panel is integrated, are widely popular. Another example is the jacuzzi, which provides a direct or wi-fi connection to the central module in the smart home system. In general, there is no limit to engineering.

How to determine the manufacturer

Of the Russian, the largest and most advanced manufacturers of acrylic baths, Bell Rado, Doctor Jet, Aquatek, Radomir products stand out, products of the Russian-German company Aquatika can also be included here. Each of these manufacturers is considered the largest, for this reason, in pursuit of status and prestige, each of these manufacturers is trying to produce only high-quality plumbing. On average, an acrylic bath produced in Russia costs from 45,000 rubles to 75,000 rubles.

From foreign manufacturers, priority in quality, and without it, the palm of priority in prices, is kept by Germany and Italy. This plumbing from companies such as Sunrans, GNT (Germany) and Artceram, BelBagno, Novellini Elysium (Italy). The quality of acrylic baths is very high, but the average price starts from 55,000 rubles and can go up to 200,000 rubles.

With more adequate prices and sufficiently high-quality products, plumbing equipment from Czech, Polish and Spanish manufacturers is on the Russian market. Of the Czech products most popular brand is Ravak. The price segment of plumbing from these countries has a very large variation from 7,000 rubles to 50,000 rubles, depending on the specific model and its functionality.

A very simple and cheap acrylic bath can be bought from manufacturers from China or Turkey. Of course, they also have brands, for example - Eago (Hong Kong), but if you take the estimated models that are on the market, you can come to the conclusion that for 6,000 - 30,000 rubles, it is quite possible to purchase sanitary ware.

What you need to look at in the store when buying an acrylic bath

Summarizing the above, going to the plumbing shop, you should pay attention to the following things:

Step 1.

We determine the shape, length, width - this is purely individual.

Step 2.

We check the number of layers in the structure of the bath itself - that is, it is cast or plastic + acrylic.

Step 3.

We look at the thickness of the acrylic layer.

Step 4.

We look at the total thickness of the bath material.

Step 5.

Pay attention to the number and thickness of the reinforcing layers.

Step 6.

Surface condition and material elasticity.

Step 7.

The skeleton device and the number of supports.

Step 6.

Availability and availability of additional functions.

Step 9.

We are determined with the manufacturer.