The alignment of the concrete base for laying the topcoat can be performed using logs, which are boards or bars. It is possible to attach logs to the concrete, either using rigid anchors or in a controlled manner. If you mount the frame on a concrete floor, then under it forms an underground, the space of which can be used for laying communication networks. Installation of the frame of the bars contributes to the creation of proper ventilation and improvement of noise insulation in the equipped room.

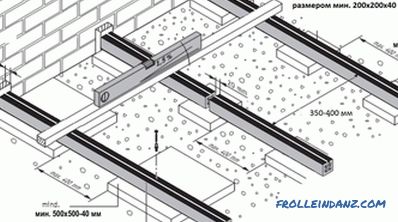

Layout of the support lags.

Use for creating anchor frameworks

Often the traditional method of creating a framework from uneven bars is used. If you attach the logs to the concrete with anchors, you can not only fix, but also press them to the base. This ensures uniform distribution of the load on the floor. The length of the anchoring should be 5 cm greater than the thickness of the beam. It is necessary to lay a layer of waterproofing made of a hard material on the floor, as a soft insulator will cause the structure to float. The insulation is mounted after mounting the frame.

To perform a lag fixation, the following tools are used for work:

- construction level;

- punch;

- hacksaw.

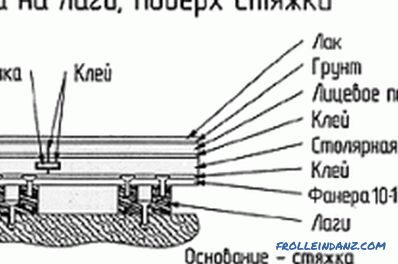

Lag mounting scheme for a concrete floor.

Materials:

- roofing felt;

- construction tape;

- anchors;

- antiseptic treated lags.

The work is performed in this order:

- Before fixing the logs, the base is thoroughly cleaned of debris and dust, then it is overlaid with sheets of roofing material, fastening their edges with adhesive tape.

- Place 2 lags along opposite walls, leaving a gap of 4 cm.

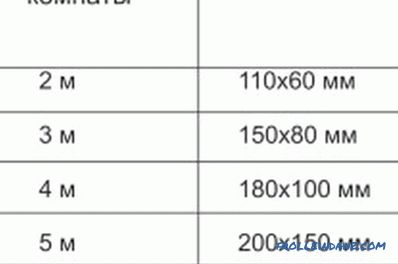

- Place the remaining bars evenly overlap, taking a step of 40-70 cm. The length of the step is taken the smaller, the larger stiffness of the material laid on top.

- The height of the boards at the walls is set using a level and tension between them a cord for orientation during subsequent installation.

- In perforated concrete, holes are drilled and spacers inserted into them.

- They make holes in the bars (2-3 in each) and begin to fix the logs to the concrete, screwing them into the bolts and placing prepared pieces of the boards under them if necessary.

Between the bars place insulation mats on which the vapor barrier membrane is mounted.

How to install an adjustable frame?

Adjustable logs can be used for leveling concrete bases with large elevation differences, which are attached to the concrete surface using plastic racks.

Lag Design

Stand bolts can be adjusted (in the range of 10-40 cm) to create the required level of height. Adjustable with bolts bars can be quickly, without resorting to additional installation work, set over uneven floor surface. In this way, it is possible to create a precisely aligned base on which you can place a finishing floor covering.

Tools required for mounting:

- drill and 28 mm drill bit;

- laser level;

- hexagon;

- hammer ;

- chisel;

- screwdriver;

- doboynik.

Materials:

- bars with stud bolts;

- dowel-nails;

- 4x16 mm screws.

Section lag depending on the span.

The work is performed in the following order:

- The surface of the base is pre-cleaned and waterproofed.

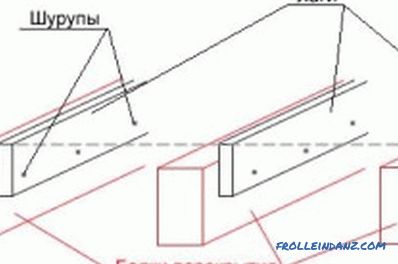

- In the bars with a drill, drill holes into which they insert the bushes and fasten them with screws.

- The rack bolts are screwed into the sleeves, taking several turns to pre-secure.

- Lay out the logs, keeping a uniform pitch between them, the size of which is in the range of 30-50 cm.

- From the open end of the bolts, drill holes in the concrete ceiling to a depth of 6 cm and remove crumbs from them.

- Dowels-nails are placed in the holes and they are deepened using a dobode and a hammer.

- Align the bars to the desired level by turning the bolts with a hexagon.

- Completely hammer in the dowel-nails, fixing the height of the wooden frame.

- The protruding parts of the racks above the upper surface of the beam are cut using a chisel and a hammer.

After the lag is attached to the concrete floor, insulation can be installed between the bars.

To level the concrete base correctly and quickly, you need to get information on how to fix the logs. All stages of work should be carried out carefully, avoiding mistakes during installation of the structure. Knowledge of technology allows you to properly fix the logs to the concrete surface, preventing the device from deforming. A floor covering made on a correctly mounted bar frame will be reliable and will last for a long time.

Didn't find the answer in the article? More information on the topic:

-

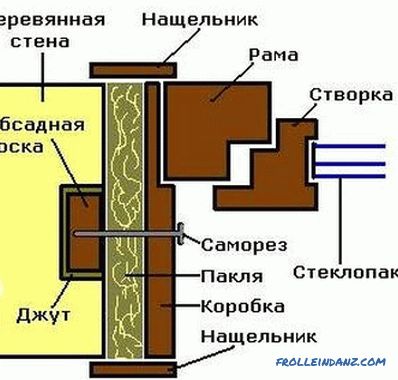

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.