Good water supply makes any building comfortable. Previously, there were no problems with its installation; after all, it was necessary to mount only pipes with taps, but now everything is different. Modern technologies have made water supply more efficient, eliminating its disadvantages.

For populated areas, the solution to the problem of lack of water is drilling a well. In order for such a system to work efficiently, it is necessary to properly connect the pumping station, which supplies water to the building constantly with good pressure.

Selection of a station

Selection of a pumping station

Selection of a pumping station

know exactly its performance. The modern market offers two types of this product - domestic and industrial. To connect the latter, you will need a special tool, and you cannot do without qualified assistance.

Domestic stations are simply connected, so you can cope with this work yourself. Moreover, such a pump is sufficient to meet the needs of the average family, so we will choose such equipment.

Choice of place

Pump in the basement

Pump in the basement

Usual locations for pumping stations - cellars and caissons. During installation, it is necessary to ensure that the distance from the equipment to the wall remains large, since during operation the pump may be damaged due to strong vibrations. Also, it should not be affected by mechanical factors.

If expensive equipment will be located in the basement, then you need to make a pedestal-type stand under it. With it, you protect the equipment from groundwater. The station should not be further 10 meters from the well.

Set up

Set up the station

Set up the station

First turn sure to read the instructions attached to the equipment.

Work must begin with the preparation of tools and the purchase of materials. Is it done? Then we start to prepare a place for our equipment.

If there is such a need, then build some kind of pedestal from a cement mortar or a simple brick for a substation under construction. Secure the installation site with prepared formwork and fill with cement. After the solution hardens, we proceed to the drilling of mounting holes. It is necessary to fasten the pump station as reliably as possible. A rubber gasket under the base of the equipment will help reduce vibration.

Installation of communications

After the installation of the station is completed, connect it to electricity and wiring the pipeline. When working with electric wires, do not forget about grounding, and when laying pipes - about reliability. The main task is to eliminate the possibility of air entering the system. If there is a vacuum in the equipment, auto power off will work. To make connections even more reliable, you can use a fum tape.

Modern pumps are manufactured with an integrated intake valve. Also, quality products have protection against dry running. For the installation of such equipment you only need to connect the required holes to the correct pipes. If your station does not have such built-in devices, then the installation will take place differently.

The check valve should be placed at the outlet of the water source, and the receiving valve should be placed on the suction pipe. Between the two valves should be installed protection against dry running. All the places where the connections were made, fasten the connecting fittings and fum-tape.

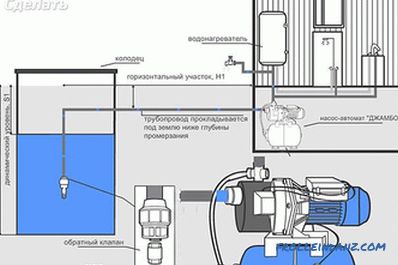

Pump connection

Connection diagram of the pump

Connection diagram of the pump

- To properly conduct connection, you need to collect the ejector. In fact, this is a tee with pipes, which later will be connected to other branches. A metal filter is installed at the bottom of the ejector.

- Now you need to collect sgon. Often it is made of two pipes with different diameters, connected by a special adapter. The sgon is mounted at the top of the ejector (on its plastic socket).

- In order to have a reliable connection to the water mains, fasten the bronze coupling to the suction outlet.

- Now we lay the connecting pipes on the place intended for them, thereby connecting the well with the pump. The trench needs to be prepared prudently.

- The plastic tube, which will later be installed on the casing, should be smoothly bent at a certain angle.

- By pushing the pipe into the knee, you can lower it into the tip. In order to maintain the tightness of the connections, use a mounting foam. After that, using adapters make connections to the highway.

- The finished ejector must be lowered to the depth previously noted in the well.

- Reinforced with adhesive tape fasten the cap to the casing.

Filter

Regardless of the purpose of the water, it is better to install the filter. This will help to clear the liquid from the sand.

The absence of a filter may render the pumping station unusable.

The filter element is mounted on the suction device. After all procedures, adjust the pump according to the instructions.

Total

Good water pressure

Good water pressure

The pumping station will facilitate everyday work, delivering water from the well directly to the house. Moreover, the liquid will come under the pressure necessary for the efficient operation of kitchen appliances (washing and dishwasher machines). Connection of such equipment can be carried out independently, saving on expensive specialists.

Video