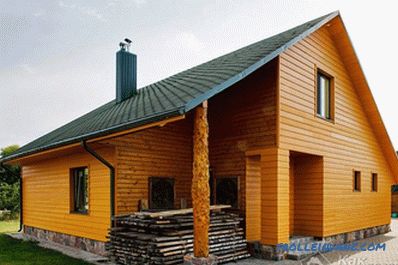

Facing the facade of the house is one of the main components of not only external attractiveness, but also reliable protection of external walls from the adverse effects of natural factors: rain, snow, sunlight. In addition to protective functions, facing the house creates good thermal insulation of the room.

Today, in the construction market you can find many options for cladding the facade. One of the popular types of finishes is siding. Facade siding do-it-yourself does not require special training, skills and abilities. Responsible approach, the right choice of material, strict adherence to installation technology, with the result that high-quality facade decoration will be provided.

Types of siding panels

Before proceeding with the cladding of the facade of the house, you must familiarize yourself with the types of siding panels and study the characteristics of the material from which they are made.

Steel

Steel siding under the wood

Steel siding under the wood

Steel siding used for cladding industrial buildings and warehouses.

Advantages:

- large selection of colors and shades;

- resistance to deformation;

- durability;

- not combustible.

Disadvantages:

- periodically requires anti-corrosion coating;

- there are dents from mechanical damage;

- a large mass increases the load on the foundation of the building, which must also be considered when building a house;

- high cost.

Aluminum

Aluminum siding is used for covering industrial and residential buildings.

Advantages:

- light, durable and durable material;

- does not fade in the sun;

- a huge selection of colors ;

- reasonable price.

Disadvantages:

- is subject to corrosion;

- deformations are possible due to strong mechanical stress.

Wooden

Wooden siding is used mainly for interior plating of residential and office premises.

Advantages:

- aesthetic appearance;

- retains heat well.

Disadvantages:

- fragility;

- high cost;

- needs constant impregnation with special formulations for increase in service life.

Cement

Cement wood siding

Cement wood siding

Cement siding - This is the newest technology for building facade cladding. Cellulose fibers are added to a conventional cement, thus, a plating resembling expensive types of wood is obtained. Special molding technology allows you to make this type of siding with any pattern. It is used for plating industrial facilities. For residential use is used in rare cases.

Advantages:

- a huge selection of colors;

- not combustible;

- durable and durable.

Disadvantages:

- a lot of weight, which will put an extra load on the foundation;

- complexity of material processing;

- facade cladding will require not only special training, but also the use of respiratory protection (respirators); 27> high cost.

Vinyl

Vinyl siding, one of the most commonly used finishes. The material looks spectacular and expensive, as it imitates many textures: expensive types of wood, stone, marble. You can also choose different colors and create an original pattern or picture.

Advantages:

- simplicity and ease of installation;

- reasonable cost;

- reliability, durability (over 20 years );

- lightness of the material;

- a huge choice of texture and color;

- you can sheathe any type of surface;

- the ability to replace multiple panels; 27> can be treated with various detergent mixtures.

Disadvantages:

- vinyl panels do not withstand strong shocks and can cause cracks.

Facade cladding with vinyl siding is the best solution for finishing the facade of a house. It is desirable that a specialized team be involved in facing the facade. Poorly laid panels will let air, moisture and insects pass to the wall of the house, and this threatens to damage it. It is possible to sheathe the facade with your own hands, for this you need to prepare tools and materials that will help in the work, as well as to familiarize yourself with the instructions.

Tools and Materials

Tools for proper installation

Tools for proper installation

Required tool:

- instruments for measuring (ruler, square, tape measure);

- knife;

- punch;

- hammer;

- rope;

- chalk;

- screwdriver;

- stepladder;

- electric saw for cutting panels.

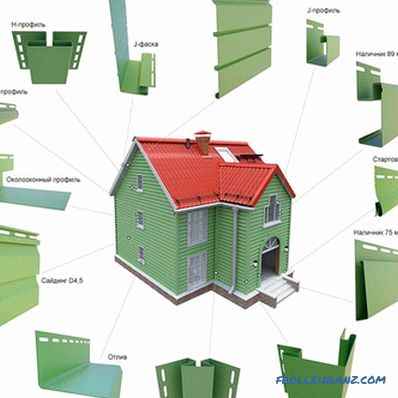

Additional elements for siding

Additional elements for siding

Material:

- exterior and interior angle;

- window sill;

- H and J-profiles;

- start and drain strap;

- soffits .

Stages for finishing the facade

Before you sheathe the facade with siding, you must clearly follow the installation technology, which consists of several stages.

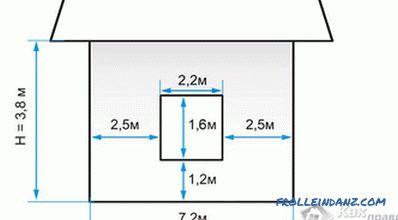

Calculations

Material calculation

Material calculation

First you need to calculate the amount of material needed for plating. Such a calculation can be done in the construction store sales consultants. For the calculation it is necessary to provide the following information:

- the area of the walls of the house (cottage);

- the size of the walls;

- the size and number of window openings;

- type of roof country house.

Having all the data for the calculation, you can independently calculate the required number of panels for cladding using the following algorithm: from the area of all walls of the house subtract the area of doors and windows, divide the resulting number by the area of one siding panel . The result is multiplied by 1.10. Thus, the area of the panels is calculated with a 10% margin.

Preparation

Prepare the surface of the walls. Clean their pollution, remove unnecessary items (pipes, trim, window sills, etc.). Gap blow out with foam or seal up with cement mortar. If the surface is wooden, then treat it with a special mixture (antiseptic).

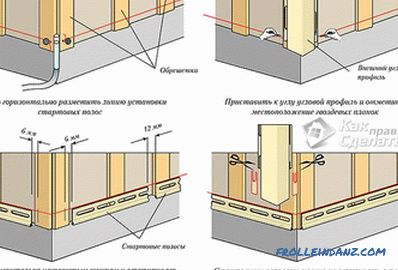

Lathing

Lathing scheme with insulation

Lathing scheme with insulation

If the house is new, then lathing not required. Provided that the old house is necessary to prepare the crates for mounting panels. For crates use wood or metal. Wooden crate is cheaper than metal. But the metal crate is more reliable and durable. For wooden crates suitable slats, which are pre-treated with an antiseptic. Iron crate is made of galvanized profile.

Insulation and Waterproofing

The next step is insulation and waterproofing. As a heater, you can use foam. For waterproofing - the membrane. The first layer is laid insulation, the second - the membrane, and then make a new crate.

Installation

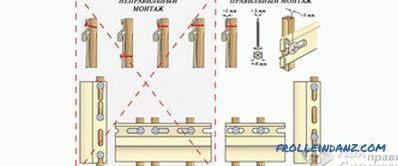

- The siding is mounted with a gap between the end of the panels and the corners of 6-8 mm. Between the panels and the crate it is also necessary to maintain a gap of about 2 mm to prevent deformation of the siding.

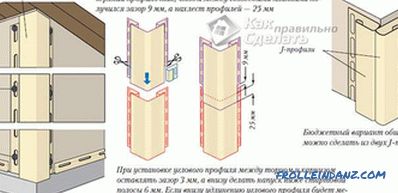

- Before attaching a new panel, it is connected to a panel attached to the sheathing. The outer corner should close the joints of the panels.

- Fasten the laths of window openings and j-profiles, including in the doorways. Profile angles overlap.

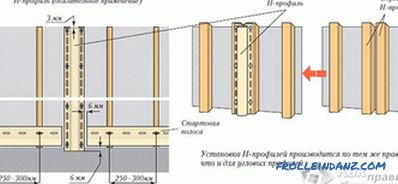

- Install the H-profile in a vertical position, leaving a gap of 3-5 mm at the top and bottom.

- Secure the finishing bar under the roof of the building.

- The first row of siding is fastened to the starting plate, and is fastened with a screw at the top and in the middle at a distance of 35-45 cm. Installation of the following rows is done in the same way.

The technological process of installing siding is not particularly difficult, so it can be done by hand.

Video

A detailed description of the installation steps for siding:

Schemes

Schemes of proper installation:

Start of installation

Start of installation

Panel overlap

Panel overlap

Rules for fastening panels

Rules for fastening panels

Mounting H-profiles

Mounting H-profiles

Mounting the corner strip of the outer corner

Mounting the corner strip of the outer corner

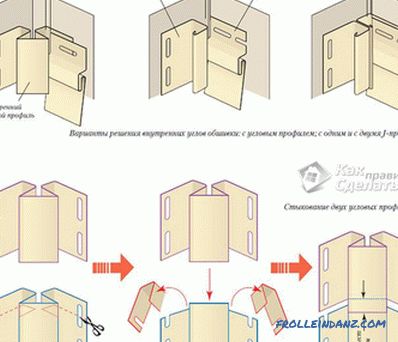

Mounting scheme for the inner corner

Mounting scheme for the inner corner

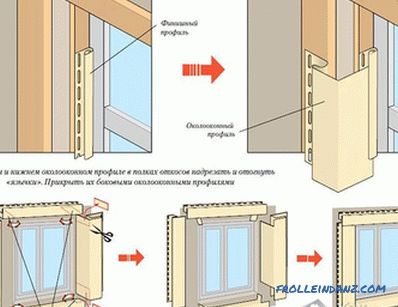

Window cladding

Window cladding