Often, due to high prices for finished structures and for a number of personal reasons, car owners decide to make swing garage doors on their own. In this article we will try to tell how to make such work, as well as provide the necessary drawings.

Types of garage doors

At the first stage of the project you should decide on the type of doors that are best suited for your specific conditions. But first of all, you should consider the known versions of the designs of this type, which include:

- hinged type, characterized by extreme ease of execution;

- recoiling;

- sectional type;

- lifting.

Note that the independent production of the last three types can be associated with certain difficulties for an ordinary artist. In this regard, we suggest that you consider the procedure for assembling a garage structure on the example of the installation of the easiest to manufacture swing gates.

Preparatory data

The manufacturing technology of swing-type gates is quite simple and does not require the involvement of any special materials and components. All you need for their construction is metal sheet blanks, profiles and angles of various dimensions, which today can be purchased at almost any building materials store.

Even before the start of installation work, it is desirable to prepare a sketch indicating all the elements used in the construction and their sizes. In drawing up the sketch, you will need to decide on such indicators of future gates as their height and width.

Based on the requirements of free passage of the car through the aperture, its width is usually set in the range of 2.5 to 3 m. The height of the frame is selected taking into account the appropriate size of the car; in various situations, this size can vary from 2 to 2.5 m.

Manufacturing of frame and sash

The manufacture of swing gates begins with the preparation of the supporting frame, consisting of internal and external frames and which is the basis for hanging the hinges.

Such a frame is made, as a rule, from a steel angle with a size of at least 65 mm. The starting material for the arrangement of the frame base of the valves can serve as a steel corner 50 mm, or a rectangular profile of the same size. After the frame for the valves is ready - you will need to sheathe it with iron sheets with a thickness of about 2 mm.

In the manufacture of garage doors, special attention should be paid to the accuracy of the installation of corner joints, as well as to ensure the strength of the prepared structure. It is for these reasons that stiffeners must be provided in it, made in the form of profile jumpers located along the diagonals. In addition, we should not forget about the working gaps, which should remain between the carrier and the frame of the door leaves (within 10-15 mm).

Installation

Gate installation

Gate installation

It is advisable to carry out all the basic operations associated with the installation of a garage door in the following order:

- First of all, the supporting frame, pre-welded from metal corners, is installed in the partially prepared opening. Its installation is performed, as a rule, after several rows of brickwork of the front part of the garage are laid, raised to a height of about 50 cm.

- At the next stage of installation work, the supporting frame is fixed (fixed) in the laying. To do this, use special metal embedded in the form of reinforcing rods. The bars of about 25 centimeters long are welded to the supporting frame and embedded in the course of laying between the bricks. On each of the supports of the frame structure, it is desirable to have at least four such mortgages.

- Now you can continue to lay out the front wall of the building until you get a full vertical trim.

- After the laying is laid out to the top of the frame - you can proceed to the installation of the lintel. As a lintel can be used as a finished reinforced concrete billet, and self-prepared section of the rails. When installing it, do not forget to leave a small gap, taking into account the possibility of precipitation of the structure during its operation.

- And in conclusion, ready-made door leaves are hinged on hinges, previously welded to the frame base.

At the end of the whole complex of works, the garage doors are necessarily tested for their functionality. This checks the ease of opening and closing the valves, as well as the absence of any deformations and distortions.

Photo

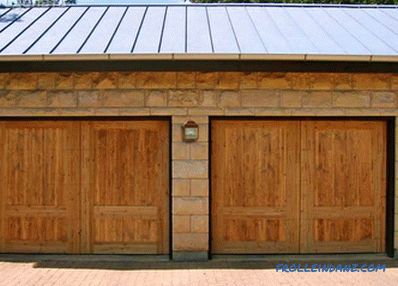

Swing type

Swing type

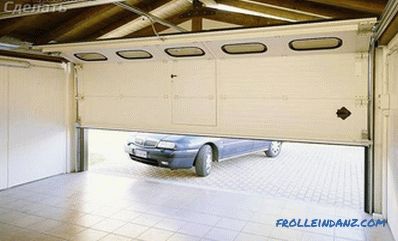

Automatic

Automatic

Sectional

Sectional

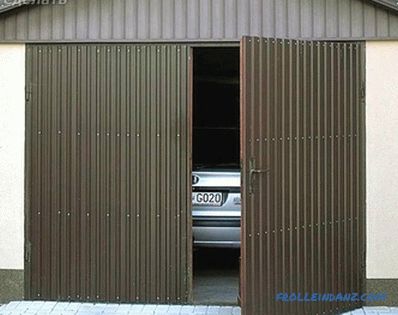

Sliding

Sliding

Lifting

Lifting

Many owners of motor vehicles are currently engaged in the installation of garage doors. If you have experience in conducting such work, leave your comments on the article.

Video