Before you start building your own home for a car, you will have to do a little but painstaking work. It is about designing and determining the optimal location for a future structure.

Garage size

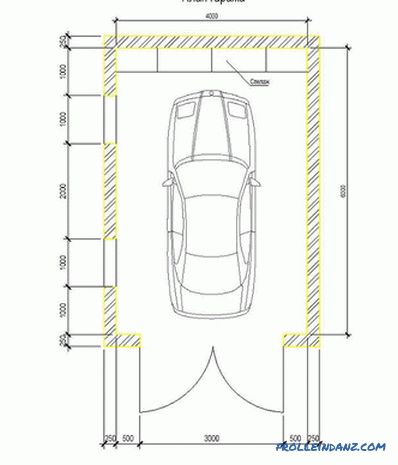

Garage layout for one car

Garage layout for one car

The approach here is strictly individual , as in most cases each garage is not just a place where your car will “sleep”, but also a convenient utility room and a place for repairing equipment.

The assignment may be:

- per machine (designed only for its storage without repair and therefore no internal additional space is required);

- for one machine with space for storing tools, spare parts and other necessary "little things" (shelves for them can be arranged at the end of a room or neatly placed on one or two side walls);

- for one car, taking into account that here you will be engaged its repair (then you will also need a "pit");

- for two cars with attendant needs, considered above.

Two-Car Garage Scheme

Two-Car Garage Scheme

If you have two cars in your family, choose the appropriate option from those listed above, adjusted for the size of the second car.

The average size of a garage for one car is 3 by 6 meters. But it is better to make an individual project just for your car or for the car that you are going to purchase in the near future (if it will be larger than you have). Park your vehicle on a large, flat platform to open the doors. Now it remains only to measure the resulting space, add the width of the passage (around the entire car), as well as the width of the shelves that you are going to hang on the walls. As a result of the calculations, you will have an internal size. To get the outer dimension, you need to add the thickness of the walls (from all sides), taking into account the internal and external decoration.

The height of the garage is also chosen individually. The optimal 3-meter internal height (after the floor and ceiling devices).

Alternatives

What could be the garage

What could be the garage

If you are not too a large private plot, a garage can be combined with one of the following outbuildings:

- with a storeroom for food supplies - it is usually attached to the building’s end, separated from it by a solid wall and making a separate entrance to it;

- with a gazebo - it can also be attached from the end of the building or placed on the roof of the garage room;

- with an additional room (this could be a living room with a bathroom, office, etc.) e.), which is usually located above the automobile room and has a separate entrance from the yard or street along an external metal or reinforced concrete staircase.

Choice of place

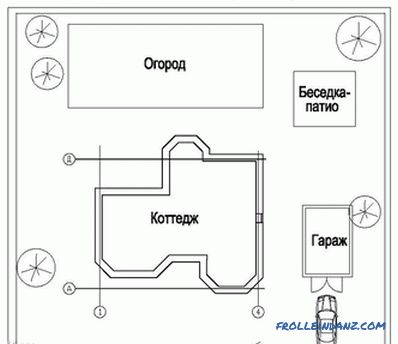

Garage location on the plot

Garage location on the plot

Garage accepted have as close as possible to the fence, but there are some nuances here:

- "move it" away from the house if you are going to repair it or someone else’s cars in it;

- move away from the fence of neighbors not less than a meter (you will need this distance for exterior repair work);

You will have to retreat at least 5 meters from the border of the road section.

We build according to drawings

Now let's take a closer look at the construction process:

- Like any large building, you need to build a garage according to the design, even if it is drawn from arms.

- Having decided on the size of the room, select a gate for it. They can be swinging, sliding, sectional and lifting. If you get the gate that was already in use, be sure to take measurements and design the construction on the basis of the finished size, so that later you do not have to perform many unnecessary operations.

- The next step is to choose the type of foundation and material from which you are going to build. A brick or small block will require a strip footing. The wooden and metal construction can be placed on a column base or simply pour a concrete support plate about 15 cm thick for it (do not forget about the reinforcement to be laid during the pouring process).

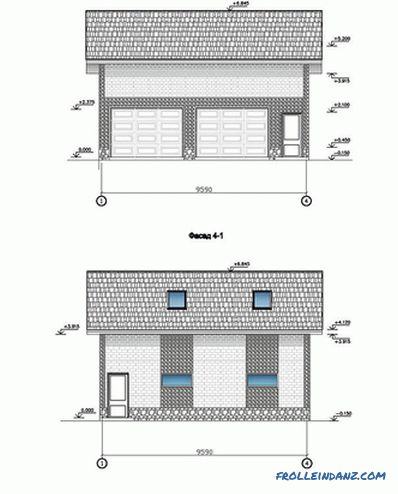

Garage drawing

Garage drawing

- The roof for the garage is usually made lean-to with the fixing of the drain gutter and drain. The slope can be sent in any direction except the front.

Location of the garage

Location of the garage

- The next step is to build the foundation.Under the strip foundation, it is necessary to dig a trench, under a columnar - several small trenches, under a solid concrete slab - carefully tamp the soil, pour about 5 cm of a gravel pad (it should also be tamped), put a formwork, put waterproofing on it the thickness of the concrete cushion and destroy it) and reinforcing mesh, pour concrete.

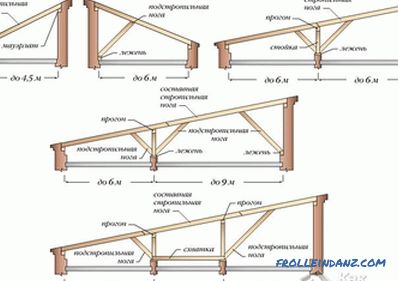

Construction of a shed roof

Construction of a shed roof

- The time it takes for the concrete to gain 90% its strength is approximately 28 days. After the concrete has hardened, waterproofing is placed on its surface, for example, roofing felt.

The upper part of the foundation (base of the foundation) must be above the ground level at least 30-40 cm.

- Install and fasten (using braces ) your swing gates (they will be fixed in the masonry as the walls are erected). If other types of gates are used, some of them can be mounted at the end of all construction work.

- Then you can start laying walls. Do not forget to vent in the wall.

- Prepared wooden truss legs, mauerlat, counter lattice and crate, treat with antiseptic and fire retardant (this will protect the wood from bugs and convert it to the category of hard-burning materials).

- On the top of the walls, the mauerlat is laid (wooden beam section 120x120 or 100x100 mm) and fixed with anchor bolts.

- Lay rafter legs along the slope of the roof, resting them on the mauerlat. At the same time the slope of the roof must comply with the normative for the chosen roofing material. Calculate the load and compliance with the angle of the selected roofing material can be in our calculator single shed roof.

- On top of the rafter beams, the wind and water protective membrane is fixed with the help of a construction stapler.

- On top of the rafter legs along the membrane we fill the counter lattice, on it (perpendicularly) - the batten, the pitch of which depends on the roofing material used.

- Roofing material is laid and fixed on the crate.

- If it is necessary to insulate the garage, a non-combustible insulation (min. Cotton) is placed between the rafter legs, and is closed on the inside with a vapor barrier.

Construction of the garage foundation

Construction of the garage foundation

- The ceiling in the garage can be made of any suitable materials (chipboard, fiberboard, MDF panels, drywall, OSB and others).

Video

From this video you will learn how to create the best conditions for a car by insulating walls and installing a ventilation system: