A wooden spiral staircase that connects the first and second floors of the building is an excellent option for almost any room. It occupies a small space, while it can be located both next to the wall and away from it. This makes it almost universal for any two-story house. Of course, you can ask for help from specialists, so that they make a spiral staircase in the house.

It should be remembered that in the middle part of the staircase the step width should not exceed 20 cm.

However, there is an alternative solution this problem. A wooden spiral staircase, made with your own hands, will solve all the problems once and for all. Of course, this is not the easiest job, so you have to make a lot of effort to build such a structure qualitatively. How to make a spiral staircase with your own hands, will be discussed further.

Required materials

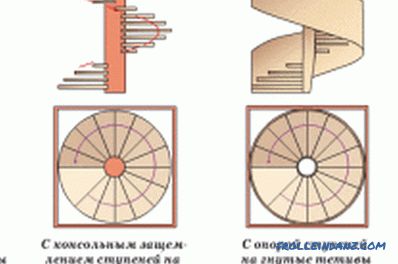

Spiral staircase dimensions.

A wooden spiral staircase can be constructed from a wide variety of wood species. Here you can use larch, oak or beech. All these materials look very interesting and add additional beauty to the interior. The tree, which is planned to be used for the construction of a spiral staircase with your own hands, should be well dried. The construction is made only from such sawn timber. Wood moisture should not exceed 12%.

To make a spiral staircase with your own hands as quickly as possible, you should use special rails for railing. The fact is that any wood is quite difficult to bend, so for the railing you will have to pre-soak wooden pieces in hot water. Only here they can soften. After that they can be bent. Today, in specialized stores, you can buy lamellae without special problems, which, connecting with each other, can form railings of the most diverse forms.

For the manufacture of the central rack, a metal pipe is used, the diameter of which should not be less than 50 mm. Otherwise, the design may not be rigid, and this parameter is very important for a spiral staircase.

Plus, you’ll have to get fighters, washers and shells. It will be a mounting tool.

Now all the materials are collected, which means that you can proceed directly to the workflow. Now you can start making a wooden spiral staircase with your own hands.

Preparation for the workflow

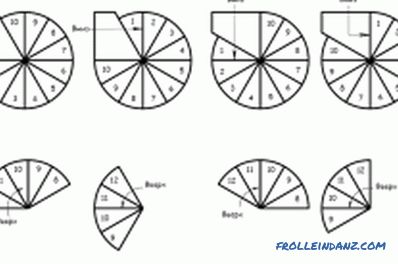

Tread design for the spiral staircase.

Of course, for a start it is worth considering a few nuances that will help you get ready for work. In this case, the staircase will look like a circle. Indeed, if you look at the stairs from above, then it is this geometric figure that turns out. The radius will be the steps, and the axis from which the readout is going is the pipe located in the middle. Here you need to think about which radius is better to choose.

If the length of the boards is less than 80 cm, then it is likely that the stairs will simply be uncomfortable to walk. When a length of more than 150 cm is chosen, the area occupied by the structure becomes too large, which can adversely affect the interior of the room. Here you need to stick to the golden mean. It is optimal to make the length of boards equal to 120 cm.

In the middle part, the step width cannot exceed 20 cm. Where the narrowest part of the board is located, this parameter can be reduced to 15 cm. In order to properly equip a spiral staircase with your own hands, it is necessary to carry out various geometric calculations. However, the data that was given above may be enough to make a really high-quality construction.

Sequence of actions

Layout of the spiral staircase steps.

Now the calculations have been made, all the data has been received, which means that you can proceed directly to the work. First, take a wooden blank. It will be used to make a step. Today it is not necessary to use ordinary boards for this, since ready-made steps are often sold in building materials stores. It is quite possible to cut a part from it according to specified dimensions. This is exactly what needs to be done at the initial stage of work. In the narrow part of the tread, be sure to cut a hole, the size of which will correspond to the size of the central rack.

Next, you need to glue those slats that were purchased. For these purposes, a special especially strong glue is used. He will allow tightly link all the details among themselves. After all, the rails will be made of the slats, which are among the most important elements of the spiral staircase design. The future confidence of the person climbing the stairs directly depends on their quality.

Assembly and design features

Types of spiral staircases.

Now you can proceed directly to the assembly of a spiral staircase with your own hands. Here, all actions must be performed sequentially. Of course, starting with the central pillar. It must be concreted into the floor. In this case, it will be held firmly enough, which will increase the rigidity of the whole structure as a whole. You can also use anchor bolts for such work.

In any case, the rack must be firmly fixed in its rightful place. It should be remembered that its location should be strictly vertical. Here, for proper work, it is imperative to use the vertical level. It will align the rack vertically. This measure is necessary. Otherwise, the whole structure may simply lose its aesthetic appearance or lose the required rigidity.

Feet one by one must be put on the stand. In this case, between them it is necessary to have a washer, a sleeve, and then another washer in series. All steps are overlapped. They must overlap each other by at least 5 cm. First you need to lay out all the steps, and then align them. Only after that they can finally be attached to each other. As you know, this is nothing complicated. That is how the main part of the entire staircase structure is formed.

On the wide side, all the steps must be fastened together. For this, support brackets are installed between them.

Thus, we can state the fact that the spiral staircase has been made, which means it can be tested for strength. Now each family member can easily go up to the second floor or attic.

Some nuances of the work

Now it is worth summing up some results, as well as emphasizing the nuances of the work.

It is best to use hardwood as the material for making wooden steps.

Spiral staircase opening fencing scheme.

Oak will look great here. This material today is quite easy to purchase. Of course, it is not the cheapest among all those on the market today. However, he has a natural beauty that no other tree possesses. When installing oak steps you should not paint them. It is best to treat them with an antiseptic, and then varnish. In this case, the natural beauty of the material will be preserved, and thanks to the varnish it will acquire a glossy shine.

If we talk about other tree species, then it is perfectly acceptable to use lime or larch for work. Such lumber is also quite high quality.

In order to carry out all the work associated with the installation of a spiral staircase with your own hands, as soon as possible, you should acquire all the necessary tools. Be sure to use the level. You will need it when checking the horizontal position and verticality of all components of the structure. The list should also include a drawing tool with which the outlines of the elements will be drawn on the boards, which will then need to be cut to size.

In addition, you will need:

- tape measure;

- hammer;

- lacing;

- screwdriver.

By the way, a wide variety of tools can be used for work related to cutting material. This may be an ordinary saw, and an electric jigsaw, and so on. It all depends on the capabilities of the person and the availability of this or that tool.

For work with a metal pipe, you will need to use an additional grinder. This tool will allow in the shortest possible time to make cutting of a metal profile.