Heat pumps allow you to take the scattered energy from the surrounding nature: air, water and earth, to accumulate and direct it to the heating of the house. Energy is also used to heat water for washing or air conditioning in rooms. This makes it possible to save money by reducing the consumption of traditional heat sources: electricity, gas, firewood. In the article we will tell you how to make a heat pump with your own hands.

What is a geothermal pump

Principle of operation of the heat pump

Principle of operation of the heat pump

First you need understand what a geothermal pump is and how it works, because it is the heart of the whole device we are describing.

It is not a secret to anyone that the positive temperature is always maintained in the thickness of the earth. In the same condition is the water under the ice. In this relatively warm environment, a closed pipeline with liquid is placed.

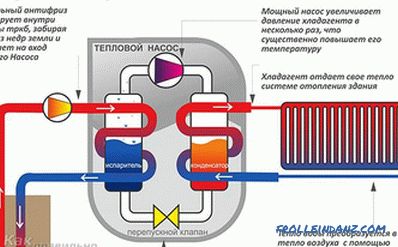

The scheme of operation for heat pumps is quite simple and based on the opposite Carnot principle:

- The coolant, moving along an external circuit, heats up from the selected source and enters the evaporator.

- There, he exchanges energy with a refrigerant (usually freon).

- Freon boils, goes into a gaseous state and is compressed by the compressor.

- Hot gas (it heats up within 35-65 o C) enters another heat exchanger, in which it gives its heat to the heating system or hot water supply at home.

- The cooled refrigerant becomes liquid again and returns to the new circle.

Pump from the refrigerator

Heat pump from the refrigerator

Heat pump from the refrigerator

Main part of the system is a compressor. It is better to buy it ready-made in a store or use one available from a refrigerator or air conditioner. All other components — the evaporator, condenser, pipeline — can be assembled by yourself. The energy of such a device will consume only the compression and heat transfer, producing at the same time 5 times more.

Using an old compressor, you need to count on the fact that its service life may be short and the system capacity will decrease. In addition, the power of the worn-out compressor may not be enough for the full operation of the system.

Some craftsmen went further and made a heat pump from the refrigerator, placing radiators inside it, heated by the warmth of the earth. Inside, the positive temperature is constantly maintained, which makes the refrigerator work constantly, heating the radiator behind it. Using a native radiator, make a heat exchanger from it (or make a homemade one), select the heat it emits.

The efficiency of such a heat pump is more suitable for demonstrating the operation of the device, since its efficiency is very low. In addition, the refrigerator is not designed for this mode of operation and can quickly fail.

Types of heat pumps

There are three types of pumps, depending on the source of heat:

"soil-water"

Ground / water pump

Ground / water pump

water-to-water

Water-water pump

Water-water pump

air-to-water

Air-water pump

Air-water pump

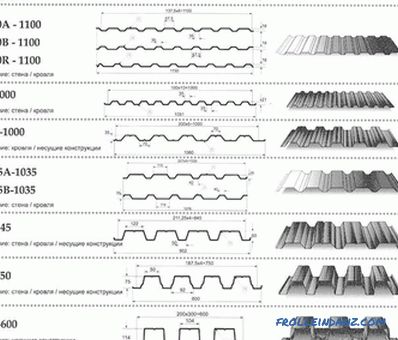

The “soil-water” installation uses the heat of the subsoil. The temperature of the earth on horizons of more than 20 m remains unchanged always, therefore, the pump can produce the necessary energy year-round. There are two mounting options:

- vertical shaft;

- horizontal collector.

In the first case, a well is drilled with a depth of about 50-100 m and pipes with circulating coolant, a special non-freezing fluid, are placed into it.

At a depth of 5 m, collectors are laid, along which coolant also moves. To heat a house with an area of 150 m 2 , a plot of at least 250 m 2 is needed, and it cannot be used for agricultural planting. Admissible only device decorative lawn and flower beds.

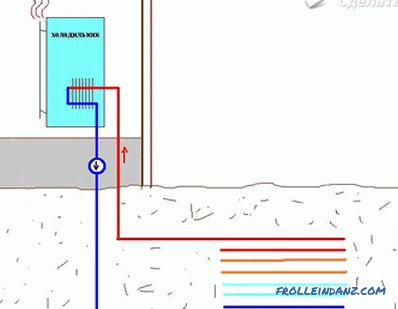

The water-to-water pump uses the energy of water from lakes, wells, or wells. Some manage to extract heat even from drains. The main thing is that the filter does not clog and the metal does not collapse.

This type usually shows the highest efficiency, but it is not possible to establish it at each country site, but a permit must be obtained for the operation of groundwater. Such devices are more characteristic of industrial production.

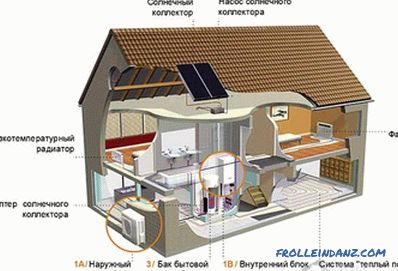

The air-to-water design is less efficient than the first two, since winter output is significantly reduced. On the other hand, during its installation there is no need to drill or dig. The installation is simply mounted on the roof of the house.

Tips

Independently installing the heat pump

Independently installing the heat pump

As already mentioned, the compressor is preferable buy ready. Any model used in air conditioners is suitable.

We assemble all other components independently:

- A stainless tank with a capacity of about 100 liters is taken as the condenser body.It is cut in half and mounted inside the coil of a copper tube with a wall thickness of not less than 1 mm. Threaded connections for connection to the contour are soldered into the casing. After this, parts of the tank can be welded.

- A polyethylene bottle of 80 liters or a pipe section is perfect for an evaporator. A coil is also inserted into it and water inlets and outlets are supplied. Heat carriers are isolated from the external environment by a foam coat.

- Now you need to put the entire system, solder the pipes and fill in the refrigerant. The amount of freon is very important for the correct operation of the pump, it is better to entrust this calculation to the heat engineer. He will be able to finally connect the installation and adjust the compressor.

- It remains only to connect the outer contour. Its assembly will depend on the type of pump.

A vertical soil-water installation requires a well and a geothermal probe is lowered into it.

For a horizontal vehicle, a collector is assembled and buried in the ground at a depth that does not freeze.

In the water-to-water system, the circuit consists of a network of plastic pipes through which coolant will flow. Then all this should be fixed in the pond at the required depth.

Solar battery

Solar battery

The air-to-water pump manifold is also installed on the roof of the house or near him.

For stable operation and protection against damage to the machine, it is desirable to supplement the possibility of manually starting the compressor in case of a sudden power outage. The cost of such an installation is quite high. Even more expensive is the factory pump. However, experience shows that the acquisition pays for several years of operation.

Video