The range of impregnation for wood is huge. Their choice must be approached carefully, so that later you don’t have to regret about damaged wooden things or destroyed walls of a house. Before you buy a coating, you should find out for what purpose the impregnation is intended.

To prevent the wood from infecting the fungus and the bacteria, it must be soaked in an antiseptic.

For work, impregnation for wood with your own hands can be used, having certain advantages and disadvantages.

Wood and its destructive factors

Today it is fashionable and prestigious to have wooden antiques in your house or to build a wooden bathhouse in your summer cottage. Wooden things are subject to destruction by such factors as:

Mold on wood leaves indelible stains, and also destroys its structure.

- putrefactive bacteria;

- grinder beetles;

- fungi.

Putrid bacteria destroy wood in conditions of high humidity. Mushrooms leave indelible stains on wood, destroy its structure. In a humid environment, mold spores are formed in the wood.

Impregnation is necessary to rid the wood of the harm caused to it by various adverse environmental factors. The process of wood preservation is implemented during the use of each stage of construction, as well as:

- during the preparation of sawn timber;

- in the manufacture of new wood constructions; fire, moisture, destruction by harmful microorganisms.

Types of antiseptic impregnation for wood

Antiseptic agents help protect the wood from grinder beetles.

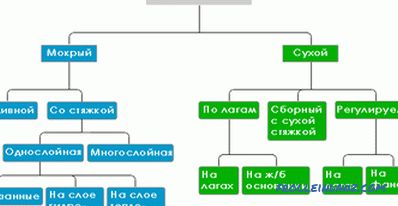

Modern protective compounds are made using organic substances, oil compositions and water-based. The most successful use of environmentally friendly means. They are chosen depending on the type of wood.

Priming impregnation is intended to save the basic material when processing wood. It is used at the initial stage of the process, before applying a varnish or paint. Treatment with primer impregnation ensures even application of all layers. Many varieties of primer processing compounds give wood the ability to not pass water.

To impart a certain shade to the tree, color impregnation is used. Wood stain emphasizes wood structure and paints wood in necessary colors. Multifunctional impregnations are capable of performing several actions, for example:

- to protect from the action of high temperatures;

- to prevent the wood beetles from destroying the wood.

Water based impregnation is versatile in operation, easy to apply, dries in a few hours. Compositions on organic solvents dry much longer, up to 2-3 days.

Nitrocellulose is a compound that provides quick drying of wood stain in 10-15 minutes.

Wood treatment should be carried out in special protective suits, masks and gloves.

A good water-based impregnation is characterized by the property of highlighting the internal texture of a wooden surface. The coating is resistant to light rays, has dirt-repellent qualities. The process of its application does not present great difficulties: drops and drips do not form on the working surface.

Water-based impregnation protects wood from spores of mosses and fungi. It can handle furniture, doors, windows. It includes pigments that have the ability to repel light rays. For applying the composition, you need to purchase a special brush, when working with which the surface remains smooth and shiny.

The composition of water-based impregnations does not include organic solvents. At their drawing no sharp smell is felt. You should purchase the following tools in advance:

- brush;

- special paint spraying device;

- nitro thinner;

- brass brush;

- primer for wood;

- colorless paint azure.

Mechanism for applying a water-based impregnating composition

Antiseptic can be applied with a paint brush.

Before you start working with impregnation, it must be mixed. The coating is carried out using a brush or other device spraying paint on a wooden surface. A tree with an uneven texture is covered by a darker impregnation.

When working with exotic wood species, the surface must be treated with a nitro thinner.

Before starting the impregnation application, the wood is swept over with a brass brush. Outside, wooden parts are coated by impregnation twice.

Products from coniferous and deciduous species are grounded with a special compound. The final coating layer consists of colorless paint in combination with azure. Impregnation onto plastic parts must not be allowed.

Mastics, impregnation for wood parts

Any master can make an impregnation for wood with his own hands, using recipes based on bitumen. These compounds are much cheaper and have exceptional properties. When applied, they impregnate wood to a depth of 7 mm.

Bituminous antiseptic suitable for working with poorly dried wood: it penetrates freely into wood fibers.

The manufacturing process of an antiseptic is simple. It is necessary to prepare the following materials for work:

- electric stove;

- bucket;

- bitumen;

- diesel fuel;

- kerosene;

- mastic.

They put a bucket on the stove, place M-5 or M-3 bitumen in it, heat it to a boil and bubbles. Then the container is removed from the stove and added to it diesel. Bitumen should become liquid in a cold state.

For the preparation of a kerosene-bitumen mixture, kerosene is used, which is introduced into the bitumen with great care. Bitumen is crumbled and combined with kerosene until it is completely dissolved in it. The kerosene-bitumen composition is thick, and before it is started, it is heated to a boil.

The gasoline-bitumen antiseptic cannot be heated: it can only be diluted with gasoline.

It is easy to apply oil products, enamels, with the exception of nitro-paint and nitro-paint, on the surface treated with the composition. The coating process consists of three stages: a primer and two paints.

Use of biocides for wood at home

Linseed oil helps provide wooden products with an even more presentable appearance.

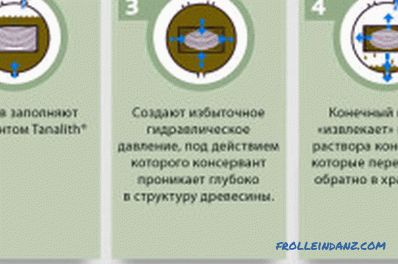

Preservatives help in direct contact with soil or water to help preserve the wood. The main components of the impregnation are compounds of copper, chromium with the addition of zinc, fluorine or boron. Biological impregnations are reliable in operation, and they are easy to make with your own hands at home. It is enough to purchase a special container and an antiseptic concentrate. To obtain the finished composition, the concentrate is poured into the prepared container and filled with water, mixing thoroughly.

Natural waxes and oils protect the wooden surface from the action of water and atmospheric factors. The oil penetrates deep into the wood, creating a special layer impermeable to gas, water, steam. Wax protects products from the outside due to the formation of a special breathable layer.

Linseed oil is an excellent material for protecting wooden structures. It is added to many tools that are used for exterior and interior work. Linseed oil helps impregnations to provide wooden products with a beautiful appearance. The oil is matched to the color of the wood by adding coloring compositions to it. Work with oils is safe for health.

Flame retardants for wood impregnation

Fire retardant impregnation for wood.

When making a wooden structure, it is necessary to protect it not only from mold, fungi, moss, but also from fire. For these purposes, flame retardants are used for wooden coatings. Special substances give the wood flame retardant properties. They prevent the spread of fire, facilitate the extinguishing of the fire and prolong the time of ignition of wood.

To impart special properties against the action of a flame to wooden structures, two types of impregnation are used: compositions based on aqueous solutions of salts and wood processing LMK.

Flame retardant composition, including non-toxic inorganic salts, is applied to rafters, lath coffers, parts of premises and offices.

Before starting, prepare the following tools and materials:

- alkaline cleaning solution;

- solvent;

- bucket;

- roller or brush.

Before starting to apply the composition, the wood is dried and cleaned of dust and dirt. The permissible moisture content of the treated wooden surface is 30%.

The composition for impregnation is stirred with a spatula before application, and then applied with a brush or roller onto the working surface. The work is carried out at a temperature of up to + 5 ° C. The coating is carried out in protective gloves to avoid contact with the skin of the hands.

The flame retardant compounds provide protection against fire I degree while fully preserving all the properties of wooden coatings. Self-made mortar is suitable for work in country, residential and industrial buildings and does not have a negative impact on human health.

After examining the market for tools that prevent the destruction of wood, you can prevent the premature destruction of wooden structures by creating special solutions with your own hands.

Didn't find the answer in the article? More information on the topic:

-

How to properly caulk a house from a log

Before you caulk a house from a log, you must decide on the material with which you make the insulation.Moss, tow, lnovatin, jute fiber, jute are used.