The center of the heating system in a private house is the heating boiler. It is he who emits energy, which is further converted, enters the coolant and heats the heating radiators. In this article we will explain how to make a heating boiler with your own hands, how to cook a boiler for heating a private house, and also provide drawings and photo instructions.

Types of heating boilers

Gas-fired boilers

Gas-fired boilers

Before starting independent the manufacture of the boiler, it is necessary to determine its type, which depends on the type of fuel, the heated thermal medium. If desired, you can build a boiler working on any fuel. Find the necessary information on the Internet resources. However, before making a choice, it is worth having an idea about the advantages and disadvantages of the most famous ones.

- Gas-fired boilers. This view should not be tried to make with your own hands, since there are a lot of requirements for them that you can hardly meet. Well, no less important reason is the high probability of an explosion during operation. Installation of a gas boiler is prohibited in the basement of the house.

- For the manufacture of an electric boiler you do not need professional skills and the availability of many materials. It should be noted a huge drawback - high prices for electrical energy. This is an ideal option for periodically heating the house in the country, but for constant use the electric boiler is very expensive.

- The boiler with liquid fuel is quite suitable for making it yourself, but the cost of fuel and the particular settings of the injectors can cause considerable difficulties during the work.

- Among all the listed options, the most optimal one can be a solid-fuel boiler, which can be successfully used as firewood.

Boiler for a water heating system

Boiler for a water heating system

Everyone knows that firewood has a high burning rate and, accordingly, do not have time to heat the room to the desired temperature at the initial efficiency. In order to optimize this process, it is worthwhile to consider two ways of self-construction of solid fuel boilers.

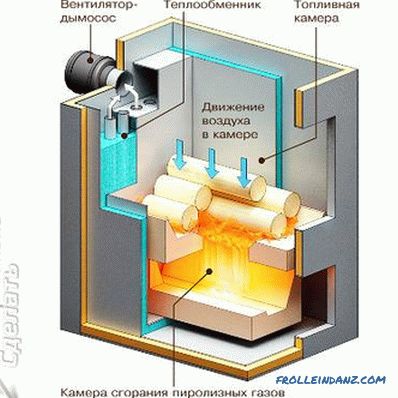

Pyrolysis version of the boiler

A boiler of this type is adapted for burning wood, its additional name is a gas boiler. The essence of his work lies in the fact that the combustion of firewood and volatile substances leaving them is carried out separately. Due to the pyrolysis process, such boilers manage to maintain the optimum temperature regime of the thermal carrier with a duration of 6 to 12 hours, without laying wood.

The principle of operation of the pyrolysis boiler The operation of the pyrolysis boiler cannot be done without electrical energy, which ensures the operation of the fan supporting the combustion process by force.

The principle of operation of the pyrolysis boiler The operation of the pyrolysis boiler cannot be done without electrical energy, which ensures the operation of the fan supporting the combustion process by force.

The dimensions of such structures are 1.5 * 0.75 * 1.7 m. The capacity of the water tank is 500 liters with the provided capacity of 50 kW. Installation dimensions may vary based on individual needs.

As a rule, for self-construction of a structure, you will need a steel sheet 4-6 mm thick, a cast iron sheet 1 cm, a steel pipe with a wall thickness of 4 mm, electrodes for welding and a welding machine. Also stock up with a centrifugal fan, a grate matching the size of the combustion chamber, an automatic device for temperature control, an asbestos sheet and a sealing cord.

At the end of the manufacturing process, the heating boiler must be tied with its own hands in compliance with the technological requirements.

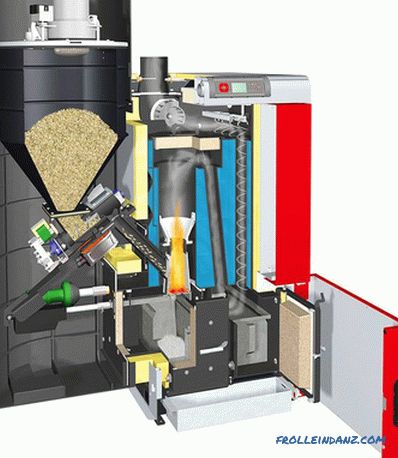

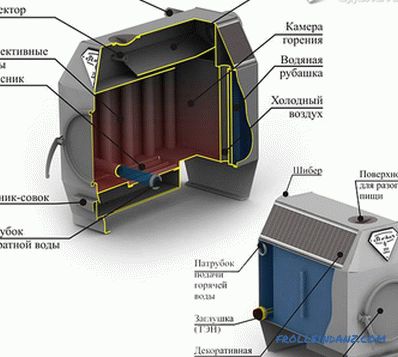

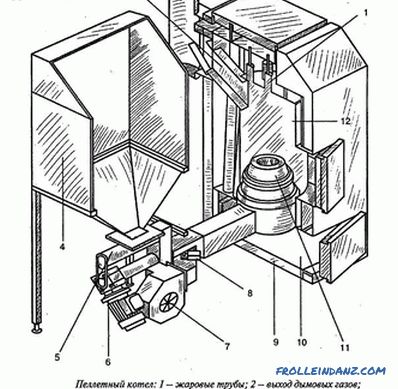

Pellet type of boiler

The principle of operation of the pellet boiler

The principle of operation of the pellet boiler

This type of boiler installation is more automated and less whimsical in the care during operation. Pellets are granulated wood, for the manufacture of which sawdust and shavings are used. Since this material is free-flowing, they are fed into the combustion chamber automatically by means of an auger or bunker.

Pellets You may have difficulty in making such a boiler due to the lack of certain electrical equipment: an electric motor to ensure the operation of the auger or bunker valve.

Pellets You may have difficulty in making such a boiler due to the lack of certain electrical equipment: an electric motor to ensure the operation of the auger or bunker valve.

The operation of a pellet boiler is carried out in such a way that it does not need to kindling or add fuel. This is influenced by the size of the bunker. Due to the principle of operation of the boiler plant, it is possible to control the amount of heat produced, due to the amount of pellets fed into the furnace.

These two types of boilers are optimal for their own production. Which of them to stop your choice, you decide.This is determined by many factors, the main of which is the need for heat and the availability of a certain type of fuel that you will use.

In any case, it is necessary to strictly follow the technology and observe the safety rules.

Video

See how you can make a long-burning boiler on your own:

This video demonstrates a solid type mine-type boiler with a heat accumulator:

Schemes and drawings

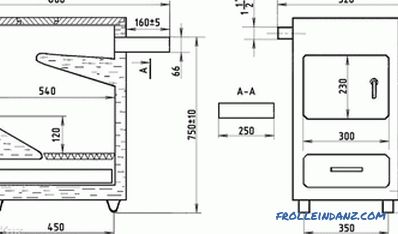

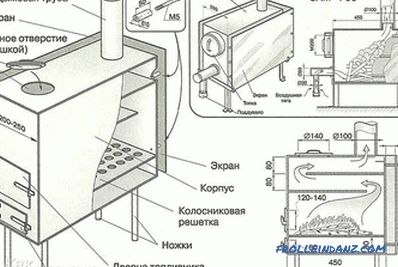

Slow-burning stove device

Slow-burning stove device

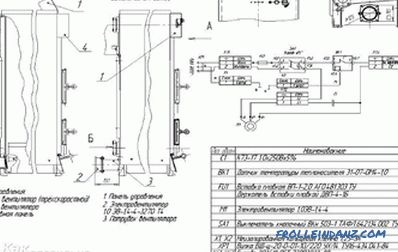

The device for a pellet boiler

The device for a pellet boiler

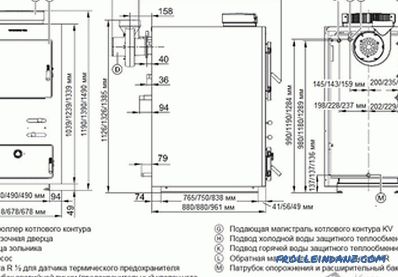

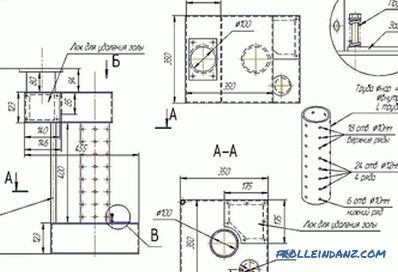

Drawing of a solid fuel boiler

Drawing of a solid fuel boiler

Drawing with dimensions to create a solid fuel boiler

Drawing with dimensions to create a solid fuel boiler

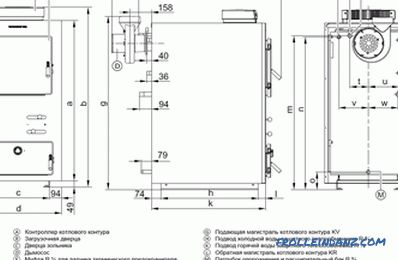

Drawing of a pyrolysis boiler Viessmann at 25-40 kW

Drawing of a pyrolysis boiler Viessmann at 25-40 kW

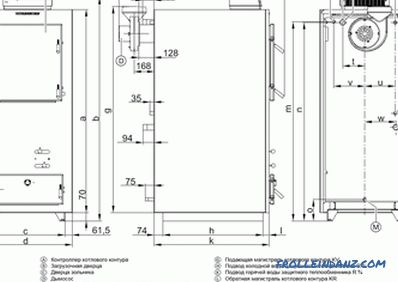

Viessmann at 65 and 80 kW

Viessmann at 65 and 80 kW

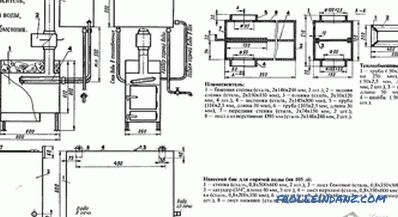

Drawing of the boiler for self

Drawing of the boiler for self

for slow burner

for slow burner

Drawing of the furnace for working

Drawing of the furnace for working

Simple and safe bath boiler

Simple and safe bath boiler

Photos

Welding work in the manufacture of the boiler

Welding work in the manufacture of the boiler

Making the boiler at home

Making the boiler at home

Converting the safe to the stove

Converting the safe to the stove

A stove with smoldering up to 8 hours

A stove with smoldering up to 8 hours

A slow-burning stove from a gas cylinder

A slow-burning stove from a gas cylinder

Home-made metal furnace

Home-made metal furnace

Reliable and economical solid fuel boiler

Reliable and economical solid fuel boiler

Heating boiler for used oil

Heating boiler for used oil

Made of a barrel

Made of a barrel

Test of a home-made long-burning boiler

Test of a home-made long-burning boiler

See also:

- geothermal heat pump with your own hands;

- how to choose a good rotary hammer.