Recently, communications made of cross-linked polyethylene have gained immense popularity, since this material is relatively inexpensive and has a number of significant advantages: an optimal combination of strength and flexibility, resistance to high temperatures, chemical compounds and destruction. The decisive role in the long period of operation is played by high-quality work on the bonding of all the constituent elements. The assembly of such structures is a fairly simple process, however, it has certain features and important points, the knowledge of which will make it possible to install pipes from cross-linked polyethylene with your own hands without any particular difficulties.

Modern shops present to the customers a huge selection of products intended for equipping communication systems of private houses and apartments. However, Rehau brand pipes occupy a leading position in this market segment. With their vast experience, German suppliers have specialized in the manufacture of high-quality consumables for quite a long time, which allowed them to acquire a solid reputation.

Features of the connection of products

The manufacturer named as the basis for such pipes was chosen the usual thermoplastic polymers with a linear structure of molecules. The only difference from competing products is the optimum elasticity of the elements, which gives the joints the required tightness. However, to perform high-quality installation of Rehau pipes, the use of welding machines operating at extremely high temperatures is required.

Types of fastening

Connection of polyethylene pipes is carried out in three ways:

- Crimp fitting. This type is the simplest and requires conventional tools. It finds its application in arranging both hot and cold communications, and also provides the ability to quickly dismantle structures in case of unforeseen situations.

- Pressing fitting. The named type of fastening allows to receive integral and reliable connection when joining several pipes. In this embodiment, the emphasis is on the restorative property of cross-linked polyethylene, allowing it to acquire its original shape after pressing. The polymers included in the composition fill all gaps and ensure tight contact.

- Electric welding fitting. The presented type is quite rare in practice due to the fact that it requires special welding machines and special skills. However, it is the most effective of all these methods.

An important point in determining the optimal type of connection is taking into account the pressure of the future communication system, since the first type of fastening can withstand up to 2.5 atm, the second - no more than 6 atm, and the third - almost unlimited .

Required tool

Before working with pipes made of cross-linked polyethylene, prepare the following set of tools and consumables:

- a set of wrenches;

- a knife and pruning shears;

- a hydraulic manual press;

- a set of connecting devices (fittings).

Preparatory work

All connection work should be started from the collector outlets. This will thoroughly ensure the complete tightness of the system and easy installation of the elements, since Rehau products bend easily. At the time of purchase fitting fittings pay attention to those types that are designed specifically for the type of pipes. Along with this, it will be useful to protect the future system from condensate or heat loss, depending on the expected temperature of the carrier.

Before installation, it is necessary to fix the pipe made of cross-linked polyethylene with double brackets included in the kit, since high elasticity will prevent the preservation of the specified shape.

The order of execution

Each type of connection has its own characteristics and a slightly different procedure:

- Crimp type provides reliable fixation of the compression nut on the cut of the pipe, while its thread should look towards the future connection. Then it is necessary to tighten and fix the split ring in such a way that the end of the pipe is at a distance of no more than 1 mm. Next to the fitting of the fastening device by tightening the cut pipe with the elements prepared on it. Finally, use wrenches to tighten the compression nut until it fits snugly.

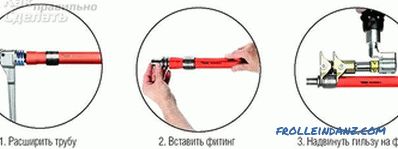

- When pressing type, you must first securely fix the sleeve-clip on the pipe cut. Then, by means of an expander, we tighten the connecting pipe to the fitting of the fitting device and hold it in this position for several minutes.Subsequently, due to the fulfillment of the last point, the pipe section will be pressed as closely as possible.

- Electric welding is carried out by fixing a special coupling to the pipe cut. Then, with the help of welding equipment, the end of the internal spiral of the fitting device should be heated. As a result, the heated polyethylene ideally takes the form of a choke and cools down, while providing the most intimate contact.

Crosslinked polyethylene

Crosslinked polyethylene

Before stretching the fitting connector, never his preliminary analysis and any manipulations to increase the reliability of the contact.

Heating system made of cross-linked polyethylene

Heating system made of cross-linked polyethylene

The procedure for connecting pipes made of cross-linked polyethylene on its own is quite simple work, however, high-quality installation requires certain knowledge and some important features are taken into account. In order for the erected communications system to serve for a long time it will be useful to study as much as possible all the information available in the public domain, focusing on the practical advice of professionals.

Read also:

- How to choose water pipes

- How to make heating for a country house

- How to eliminate a leak in the heating system

- How to correctly install heating pipes

Video

You can learn more information about Rehau pipes from Alexey Zemskov's video: