Cracks in a wooden floor always appear unexpectedly. And although they are invisible in the first stage, that is, when they appear, these defects may indicate many problems in the house, ranging from the creaking of the floor, the appearance of rodents and ending with the destruction of the coating. Therefore, to seal the gaps in the wooden floor is a necessary task for any owner who is faced with this problem.

The gaps in the wooden floor lead to creaking, rodents and surface destruction.

What are the causes of the problem and how to deal with it?

Depending on the cause of the cracks in the floor covering, further work will be needed to eliminate this problem . A common problem that causes crevices is the creaking of the floor. By itself, this phenomenon does not lead to deformation, but the sign itself already indicates the presence of any defects. In addition, the so-called walking floorboards may occur due to improper installation.

Seal the gaps in the wooden floor with slats.

To eliminate this problem, antibacterial silicone should be used. But before applying it, it is necessary to prepare the surface, namely to make a dry and then wet cleaning, to dry the surface, and then fill the existing voids with this tool. For this, it is best to take a mounting syringe that allows you to carry out the specified work.

Another reason may be insufficient adherence of the floor. To determine the degree of complexity of the problem, it is necessary to remove the fillets, and then determine what size the gap has. If it is not more than 1 cm, then it can be eliminated with a tow. When the size of the defect in the range from 1 to 3 cm should be putty, then install a new baguette.

If the gap is large, then more careful intervention is required, which includes a complete search of the boards that make up the outer layer, or the sealing of defects, which requires foam or foam.

A frequent problem is rodents, conducting their harmful activities, from which the flooring suffers. In this case, the capital replacement of all damaged materials will help, and so that harmful rodents no longer disturb the floor, you need to smear the places where the traces of the activity of mice are visible with cement with broken glass. The remaining small cracks can be eliminated with putty.

Application of various materials

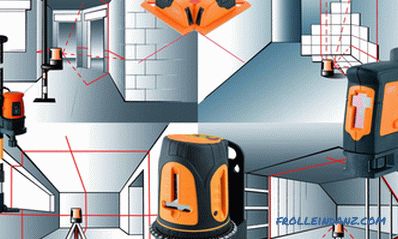

Ways to seal the gaps in the floor.

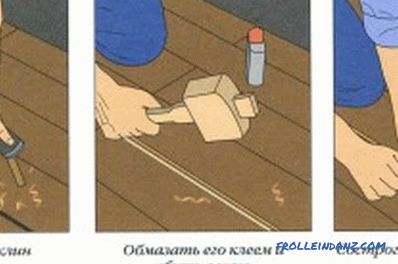

How to fill the gaps with a certain material? Most often used to eliminate this problem Reiki. To use them, it is necessary to treat the existing slots with a router, and then select the most suitable rails. A good material is pine wood. Its wood has a low cost, and the material is well processed.

After selecting the material, it is necessary to prepare an adhesive, then lubricate them with the slot opening and the workpiece. Glue is easiest to apply if you use a container that usually contains sealant. The tank has holes in the sides.

Then you need to take the workpiece, insert it into the slot and fix it. Voids need to be filled with a mixture of adhesive, which was previously mixed with sawdust. After that, you need to polish the boards, which will require a grinding machine. At its use it is recommended to put on goggles and a respirator.

That the joint did not stand out, you need to remove it from the appearance. To do this, the treated board should be sealed, which will require masking tape. After sticking this place you need to paint over varnish, choosing the desired color. In this way, it will be possible to hide the work done, and the surface itself will appear intact and not subjected to repair.

Scheme for terminating cracks with wooden wedges.

You can also use tow to seal the gaps and other defects in the wooden floor. It must be mixed with PVA glue, then the material is laid on the destroyed surface. After the material hardens, it should be painted with varnish of the desired color.

You can also make a gap with plywood. To do this, plug in the formed hole and fill the chipboard layer on top of them. This method is suitable for a radical renewal of the floor, when there is not enough time for such work. After laying chipboard, you can begin to decorate.

Epoxy glue will help to fill the gaps, the main advantage of which is quick hardening. To use it, mix epoxide and hardener. The mixing proportions are equal. In the mixture you need to add a solution of cement, and then apply the mixture to the shrinkage sites. Thread the cord through long gaps. The hardening occurs quickly, at its end the surface of the floor is varnished.

Methods for solving the problem

All methods for eliminating gaps are combined into two groups. The first is represented by the dismantling and subsequent bulkheads of the floor surface. To do this, you need to remove all the boards with the help of scrap; a strong material is selected. Next, laying the floor is made anew, with the boards being customized and strengthened. The indicated method is suitable for those situations when there are many defects, and the gaps themselves are large in size.

The second group includes a partial repair of the surface. This process involves trimming the floorboards and filling the existing gaps. This method is suitable for those situations where the floorboards are of satisfactory quality, and the available gaps are present in a small amount. Elimination of defects is carried out with foam or mixtures of various means. For larger crevices, wooden wedges will fit, which are fully driven between the boards.

Combination of several materials

Using glue and sawdust

The first step is to fill the sawdust into a bucket, then pour boiling water on them and stir until a homogeneous composition is obtained. After that, the result is left for a couple of hours, during which the mass should swell and cool, after which glue is added to the sawdust. The mixture is again stirred, as a result, the composition must be viscous.

Before proceeding with the work, it is necessary to clean the slots of debris and dust, then you can start applying the composition, which will require a spatula. The surface must be leveled, and the composition should be given a time of 2-3 days for it to completely dry. After the expiration of the specified time, the surface must be sanded.

To solve the problem, there is another composition based on glue and sawdust, only now cement is added to it. To prepare the composition should take 15 parts of water and 2 parts of glue. The mixture is cooked until completely dissolved. Then add 5 parts of cement and sawdust. To make a mixture of the desired color, you can add oil paint, pre-rubbed.

Before starting work, you need to clean the cracks, and then lubricate the gaps with adhesive obtained earlier. The mixture is only used hot. After it dries and hardens, polish the area. It is worth noting that all the irregularities and roughness should be eliminated. Full term drying of the composition is two weeks. After this time, the floor surface can be washed.

Application of paste and other methods

Tools for sealing gaps in wooden floors: hammer, nails, pliers.

To eliminate the gap in the floor, you can make a composition of paper. This requires paste and unnecessary newspapers. It is easy to make a tool, since it is necessary to tear the newspapers into small pieces, then pour water on them. Kleister is prepared separately, you need to add a little wood glue to it. Making a simple paste, you need to add starch and flour in boiling water, then cook the composition in a water bath.

As a result of the boiling, the paper will swell, after the process is complete, the water should be drained. This composition must be added to the paste, a thick substance will turn out. It is used to fill the holes in the floor, then you can not be afraid, as the composition is resistant to water and other external factors. This method is suitable in situations where you need to seal the floor before painting it.

To eliminate large defects, more complex techniques are needed. The first method involves soaking the twine in wood glue. Next, the product caulk the gap, using a hammer and a wedge. After the polymerization of the adhesive, that is, after a few days, the remaining irregularities need to be filled, which will require putty. The result of the work is aligned.

The second technique is done with slats or wedges that are driven into the holes in the floor. It is important to choose the right size, as the wedges must match the size of the gap in order to completely cover it when driving.

Thus, it is possible to eliminate defects in the floor by resorting to several methods. In this case, there are a large number of materials with which you can solve this problem.

But first of all, you should pay attention to the root cause of the cracks, otherwise defects will arise again, which will require new repair measures.