The durability and quality of the future topcoat depends on how well the surface preparation is made. To do this, it is important to know how to level the floor under the linoleum, as well as what materials can be used.

Hard putty of a concrete floor.

There are many methods of leveling the floor for further laying linoleum, but only a few are the most common ones. For self-leveling, as a rule, plywood, self-leveling compounds and putty made on the basis of PVA are used.

Tools and materials for leveling the floor with self-leveling mixture

- spatula;

- reinforced mesh;

- stapler;

- leveling compound ;

- mixer;

- rubber mop;

- needle roller;

- waterproofing;

- logs;

- self-tapping screws ;

- acrylic putty;

- waterproof primer.

Technology of leveling the floor with special compositions

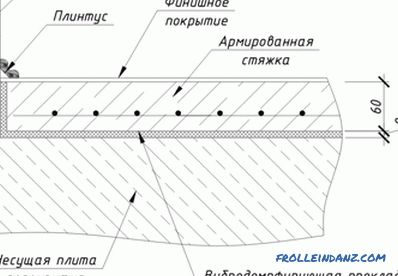

Scheme of floor construction with linoleum on the ground.

Leveling the surface with the help of special mixtures before laying linoleum implies an initial installation of the lag. If their installation is made on the surface of a wooden floor, then all the boards that are poorly fixed should be fixed to the logs with self-tapping screws, the caps of which should be driven below the floor level.

The wooden floor must be prepared, for this, the gaps and grooves between the boards will have to be removed, which will be acrylic putty, which can replace the mixture for leveling, the latter must be diluted to the thickness of the putty.

As soon as the base is dry, it must be coated with a moisture-proof primer, which will ensure high-quality adhesion of the self-leveling compound and wood. The walls to be pasted waterproofing.

In order for the self-leveling floor to gain additional strength, you should use a reinforced mesh. It will need to be strengthened to a wooden surface with a construction stapler. The grid should be laid with an overlap of 5 cm.

After you can proceed to the preparation of a solution of the leveling mixture. You can stir it using a construction mixer, and an electric drill fitted with a special nozzle will do. Such mixtures should be used immediately after preparation. The mixture must be poured into the space between the lags, leveling the surface with a spatula and a rubber mop, the lags will act as beacons. You can get rid of air bubbles with a needle roller. Now the mixture can be left to dry completely.

Leveling the floor with putty

Leveling the floor from wood for the subsequent laying of linoleum can be done with a putty made on the basis of PVA, and sawdust is also added to this composition. This floor leveling technology is an excellent solution when you have to work with the overall premises. Such a decision is also chosen for its budget.

To align, you will need to clean the base.

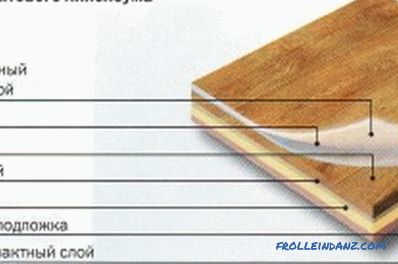

Structure of household linoleum.

After to the surface you need to nail the slats, which will serve as beacons, their installation must be done on the level. After you have to do the preparation of the mixture, which should be composed of sawdust and PVA, the composition after mixing should resemble the consistency of thick sour cream. Sawdust should be moistened in advance, and after squeezing, it will prevent them from absorbing liquid from the glue.

In those places where there are pits, the floor should be applied in several layers, each of which should be allowed to dry. It should be noted that such an alignment involves a long stage of drying the surface after applying the mixture.

Leveling the surface with plywood

Floor alignment is most often performed using the plywood laying method. To level a floor thus turns out most qualitatively. For work, it is recommended to use material of the FK brand, class from 4/4, its minimum thickness should be equal to 12 mm. If the rough base is sufficiently even, it is permissible to lay plywood, the thickness of which is equal to 8-10 mm.

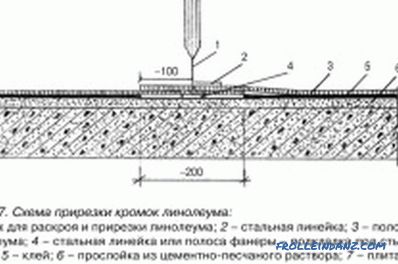

Linoleum spreading.

Before leveling the floor under the linoleum using plywood, beacons should be installed, in the role of self-tapping screws, they must be positioned on a level on the surface. As a rule, lighthouses are mounted at the corners of squares, the side of which can be equal to the limit of 25-30 cm. A screwdriver will allow you to install the lighthouses. Only then you can start laying the log, which can be made of plywood, they need to give the appearance of strips with a width of 30-40 mm.

On the basis of the floor, logs can be fixed with glue intended for working with wood.It can be a PVA Moment or a PVA Joiner, self-tapping screws will act as an alternative solution for fasteners. In the space between the lags and the boards, in the intervals between the lighthouses should be laid bars of plywood, after having smeared them with glue.

Then you can start preparing plywood for laying on the floor. Sheets can be given the form of squares, each of which has a side of 60 cm. This method eliminates the formation of waste, since such squares can be obtained by cutting the sheet into 4 parts, the standard size of each will be 125x125 cm.

Scheme of leveling the subfloor with plywood.

It is impossible to level the surface of the floor under linoleum using defective sheets. Errors can become noticeable after the cutting process - on the ends of the squares, a separation can occur, which, as a rule, cannot be seen in whole sheets. Such items to be replaced. After you can level the surface of the floor by mounting plywood on logs. It is necessary to follow in the course of the laying, so that the joints of the squares fall on the lags.

Before leveling the floor under the linoleum using plywood, you should know that you need to lay the sheets with some offset so that they are laid like bricks in the masonry. This indicates that it is unacceptable to cross 4 seams at one point. If necessary, plywood can be trimmed to size.

You can cut a plywood sheet and save material by laying the sheet on the floor before mounting the lag. Then it should be marked with chalk, where the plywood sheets will be joined. So it will be possible to fix lags in those places where necessary.

Level the surface with plywood by fastening the latter to lags with self-tapping screws.

After laying the plywood, thin sheets of fiberboard should be nailed to it, then glue can be applied to the floor surface and glue the linoleum. It is important to ensure that the joints of the substrate and the topcoat do not match. Otherwise, you can get the formation of cracks.

It should be noted that any preliminary leveling of the floor will slightly raise its level, for small rooms such a change will be very noticeable.

Lay the linoleum qualitatively only when the base is properly prepared, because the soft coating can reveal all the flaws in the base surface, and later they will become a place where the linoleum can become depleted and tear, it will require replacing the coating on new. Thus, good foundation preparation can help save money in the future.

Didn't find the answer in the article? More information on the topic:

-

Modern timber houses: exterior finish

Built houses from a bar: exterior finish and its features. Various cladding options. Technology lining the structure of the timber. Materials and tools needed for work.