The circular saw is necessary during construction or repair. This is a kind of circular saw, the choice of which must take into account not only the parameters and characteristics, but also the features of the tool. This choice is quite simple to make, but first you need to clearly define the purpose for which the equipment will be used. It is on the destination that the power and performance of the equipment depend to a large extent.

The choice of a circular saw is quite simple to make, but first you need to decide for what purposes it will be used.

Circular saws for metal

Often there is a need to work with metal billets, pipes that have completely different characteristics like wood. Requires high engine power, discs that are designed only to work with metal and various alloys.

The circular saw for metal has a slight emission of dust during operation, as there is special protection.

Such devices have the following parameters:

- high performance and power;

- labor-intensive work less;

- noise level during operation not so large;

- during operation, the emission of dust is small, as there is special protection;

- the saw blade's resource is considerable, as it is associated with heavy loads;

- it is possible the implementation of cutting "bevel";

- no burrs on the treated surface.

Immersion Circular Saw and Cordless Disk

Selection sometimes does not do without purchasing a submersible saw. Such equipment is used to work with gutters in the manufacture of grooves, cutouts. For example, if you want to make an opening for mounting the shell, then this is the immersion saw that becomes indispensable. Such a tool is convenient for home repair. It allows you to cut not only boards or metal blanks, but also laminated coatings, plastic and much more. The cut is qualitative and even, it is possible to perform the kerf in the perpendicular and in the parallel direction. The depth of the cut can be adjusted, which is very important. There are automatic saws.

The immersion circular saw is used to work with chutes, in the manufacture of cuts and grooves.

Today, battery equipment is often preferred because it is more mobile and allows you to work in difficult and hard-to-reach places. Such a saw does not require an electrical network or constant filling of fuel into the tank. All this increases productivity, makes work more comfortable. Circular saws are recommended for high-altitude work, on rooftops, during construction, where there is no possibility to connect to the network. Care should be taken when choosing a battery, since its capacity must be sufficient to perform a certain amount of work . The battery can be prepared and spare, but too frequent changes require constant recharging, and this reduces productivity, takes time to be replaced.

Functions and characteristics of saws

The circular saw should be selected with full responsibility. It is necessary to take into account numerous parameters that affect the functions and characteristics of the equipment. This is extremely important, since the choice of a device depends largely on how convenient it will be to work with it, which parameters and for what are necessary. For example, professional equipment for domestic purposes or for minor repairs are superfluous. This is a waste of money; it is not so convenient to handle such a saw, as its weight is considerable.

The battery on the saw blade must be powerful so that you can charge it as little as possible.

Too many functions are unnecessary in this case, they make the cost of equipment high, but in fact they are not used at all. The same applies to when the equipment is necessary to perform complex and lengthy work requiring the quality and power of the tool. Therefore, taking a household saw to save on cost is not the best solution. It does not have the required work resource, its power will be insufficient, and the functionality is not so extensive. This also concerns the choice of the disk, which should correspond to the work as much as possible.

Selection parameters

The choice of equipment is based on the following parameters:

Durable plastic is used for the circular saw, but sometimes manufacturers offer cases made of metal.

- Motor power. Circular saw must have the necessary power to cut turned out not only smooth but also fast, it was possible to process those materials for which the equipment was purchased. With proper power, it is possible to process solid materials, the thickness of which is significant.To perform simple repairs, high power is no longer needed; here you can get by with a less powerful engine. We must remember that power has an impact on the weight of the device. The more powerful the circular saw, the greater the weight of the equipment. If you buy a powerful one, then you have to remember that considerable weight creates difficulties, your hands get tired quickly.

- The material used to make the case. Durable plastics are taken for the circular saw, although manufacturers offer cases made of metal. The effect for which the saw is used also has an effect. For household or semi-professional is suitable plastic housing, it can withstand the necessary loads. Resistance to various loads and damages is important for a professional saw, it is best to take metal cases. But we must remember that the weight of the equipment will be greater.

- It is necessary to pay attention to the design of the handle. Best of all, if the position of the handle will change. The equipment in this case will be more convenient to use. If work is being done in a hard-to-reach place where the direction of the cut is one and the handle must be kept in a different position, then changing the position of the handle will be extremely important. If the equipment has the function of turning the handle, this increases productivity, facilitates various operations.

- Battery. For chainsaws and network-powered devices, the scope is somewhat limited. For the first case - this is the constant availability of fuel, it has a negative impact on the weight and size of the gas tank. The network device requires a permanent connection to the electrical network, which in many cases is simply impossible. For example, during the construction of a house, the use of a fixed mains is not always possible. Therefore, in such a situation, it becomes important to have a battery. Circular saw can be used in various cases, but its weight is more, the battery increases the size of the case. Batteries of saws possess specific characteristics, a scope and a resource of work.

- Selecting a blade for the saw. Here it is necessary to show utmost attention, as there are no universal saw blades. Some discs can only be used for metal, others only for wood. All this makes a careful choice.

- Availability of electronic control system. This factor has a strong impact on cost, but also on the quality of work. Such systems include adjustment of the speed of rotation, the position of the disk. Electronics can be useful, especially if work is planned intensive and long.

- Availability of the stationary use function of the circular saw. For a hand saw, the option of using in one position on a special table may be required. For this purpose, a special bed is used, which is reinforced at the desired height and in the position that best satisfies the working conditions. Not every saw has such an opportunity, it is very important to take into account if you need to cut a large amount of material, including boards and metal blanks.

Circular saw blades for the circular saw

To ensure the quality of material processing, you need to carefully consider what the device is used for. There is no universal saw blade, so when buying, you must immediately take into account what material will be handled.

Experts advise to keep a few disks in stock that can be easily and quickly replaced if necessary.

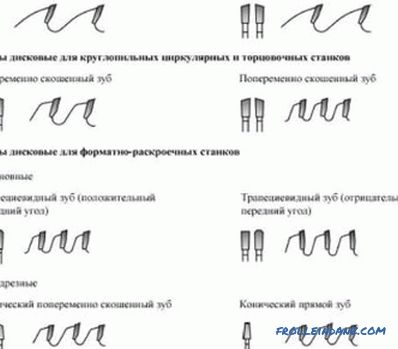

All discs for circular saws produced today can be divided into:

Different discs should be used for cutting different materials.

- The saw blades for wood, which are produced from hard alloys, have teeth with a positive angle. The number of such teeth is small, it reaches a value of 32 pieces when landing on a disc of 30 mm. Cutting is quick and easy. The disk is used to work with coarse wood, the return stroke becomes impossible, since the back of the tooth is made straight. It is possible to install a narrow pin to prevent turning.

- Discs for circular saws and for formatting devices. They are distinguished by the presence of teeth with a positive aggressive angle; there is no transition ring. The number of teeth is equal to 28 when landing in 30 mm. The disk is used to work with hard and soft wood, for plywood, cladding boards, raw chipboard.

- A saw blade with the ability to use for various types of wood and for metal relatively thin pieces. The number of teeth is 66 pieces, landing - 30 mm. The disc is made of hard metal, the cut quality is excellent. Such a disk for wood can be called universal, but for working with metal it is still better to choose a specialized one.

- We recommend the use of a special disc for metal work.This allows high-quality processing of workpieces, but the saw itself must be the necessary power, have functions adapted to perform such work.

The circular saw is not so difficult to choose if you pay attention to the necessary characteristics and performance. It is required to select disks for performance of certain types of works. If you take into account all the parameters, you can purchase convenient and reliable equipment that best meets all the requirements and conditions.

Didn't find the answer in the article? More information on the topic:

-

How to choose the bits

for the screwdriverBits for the screwdriver: how to choose high-quality nozzles. 3 rules on the choice of bits. The choice of bits depending on the brands: nozzles of types Sl, Pz, Torx. Selection parameters according to generally accepted characteristics.

-

Nuances of the circular saw device

Device circular saw: design features, main categories. Requirements for a circular saw. The right choice of device and drives to it. Basic security measures.

-

Sharpening the saw blades yourself

Sharpening circular saw with his own hands, a description of the structure of the disc, as well as the basic principles of sharpening. What you need to know about grinding wheels? How to easily make a tool for sharpening the house?