Houses from a bar are durable, strong, beautiful, warm, not very expensive. But they need an exterior finish. When building between the bars there are very small gaps. No matter how hard you try to lay them tighter, these gaps will still remain. They are dangerous because the excess moisture penetrates the house through them, the wind blows. As a result, soon the building will need repairs. To avoid this, the structure needs to be caulked.

A tool for the roaster.

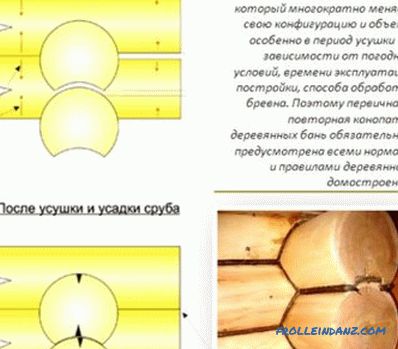

A caulk of a house made of lumber increases the life of the building, protects it from the negative impact of the external environment, and makes the house warmer. It is necessary no matter what material it is made from - rounded, glued or profiled bar. Structures are subject to shrinkage, therefore after a while cracks between logs can increase.

Felt, moss, jute, hemp and tow are used for the caulking iron.

Methods for caulking the house from a bar.

All these materials have common properties:

- natural, natural;

- they retain heat in the room;

- they are not liked by parasites;

- allow the house to "breathe";

- high service life (more than 20 years);

- do not absorb moisture.

Felt - linen material in the form of a tape. Moss - sphagnum, grows in the swamp, used before in villages and villages, you can assemble yourself. Jute - make jute from a plant that grows in countries with a tropical climate. Hemp - hemp fiber. Tow - the remnants of flax from the production of ropes, in appearance resembles hair.

Stages of caulking iron

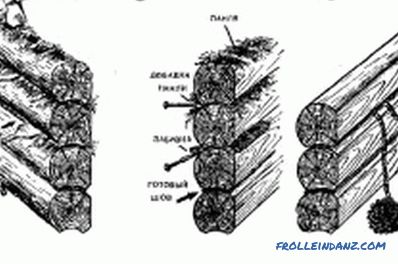

Caulking houses from a bar can be done immediately after construction or after 6-12 months, that is, after the building has shrunk, in warm, dry weather. You can plug gaps in 2 ways: stretching - from the material they make tapes, which are tamped into the gaps between the logs; into a set - they make tapes, wind up into a ball and take loops out of it, and then close the gaps with them.

House caulking tool.

The gaps should be closed not only outside, but also from the inside of the building. First, you need to calculate the required amount of material: add the length of all seams, and increase the resulting value by 2-3 times. A caulking log is made on all walls of the building. It makes no sense to insulate only one, since it does not protect against external influences.

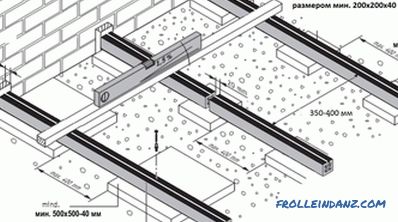

The following tools are useful for insulating gaps between logs:

- tape measure;

- steel blades of different sizes with a wide and narrow flat blade;

- rubber mallet.

Begin work from the bottom seam. Moreover, it is necessary to seal it around the perimeter of the house, and not just on one wall. You can choose any way cauldron building. It is necessary to take a piece of material and tamp it into the walls with metal blades. Where the logs are very close to each other, a rubber mallet must be used for tamping. First, the walls are caulked on the outside, and then on the inside. Remember that you need to close the joints between the bars along the entire length. Be careful and careful, you can accidentally increase the gaps between the logs so that they will be hard to shut up with insulation.

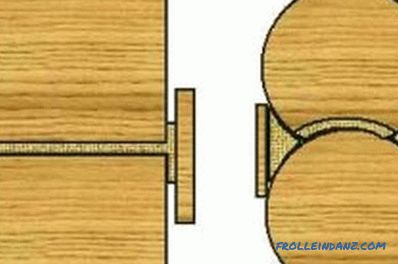

The process of caulking the walls of a profiled bar differs from the rounded one. The first type of log has a rectangular shape: one side is flat, the other is figured (there are grooves). Many people think that the house of such material does not need to caulk, but it is not. Sometimes the gaps are plugged twice: during construction and after shrinkage. In contrast to the profiled bar, rounded have a rounded shape on all sides, but the contact area of the logs is much smaller, so more material will be needed for the caulker.

Didn't find the answer in the article? More information on the topic:

-

How should I properly caulk a bath?

Instructions on how to properly caulk a bath. A list of tools for the job, recommendations for choosing a compactor for a log house, as well as a description of two caulking methods.