Building a frame house with your own hands is very relevant. This is an opportunity to get additional carpentry skills and save money on the construction team. Moreover, the erection of a frame house with their own hands is feasible, the main thing is to correctly observe the technology of its construction.

Prefab houses are gaining increasing popularity. They are built quickly with minimal cost.

Start of construction

The first thing to think about is the project. Any house from a bar requires it. If the budget is quite limited, then it is better to acquire a ready-made project, because an individual will cost more. But after the construction we can say that this house was not only built personally, but also initially personally invented and designed.

The great advantage of frame houses is their ease of construction, good thermal insulation and comfort. The foundation itself is based on a frame on which a heat-insulating layer is subsequently attached. The decor of the facade can be done with any building materials, which is full of modern construction market.

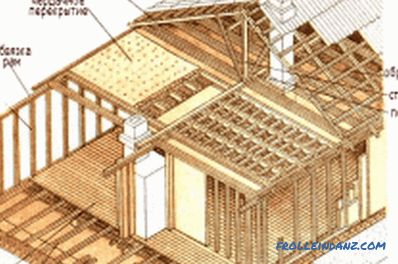

Schematic of the frame house.

There are 3 basic methods for assembling a frame house:

- frame-frame;

- frame-shield;

- half-timbered.

In the first version, the frame is assembled at the working construction site itself. It is very convenient that in such an assembly can be used in different thickness of the beam. At the same time, the construction is quite economical, and any architectural fantasy can be realized. Modern insulation allows you to organize a good thermal insulation of the facades of the building.

The second option implies assembly using ready-made factory VULTURE panels. This method is convenient because you can immediately build windows, doors and engineering communications into a house from a timber. This panel has a base of expanded polystyrene, sheathed on both sides of the RSD, which makes it multi-layered. Built-in timber provides the necessary rigidity and helps fasten the panels together.

The latter version has a framework frame filled with stone, brick or clay. The most expensive cost method of construction.

Tools for building a frame house.

If we consider the methods of building a house with our own hands, then the frame-frame variant is the only one that in this case will be acceptable. With this option, do not worry about professional construction equipment. Therefore, after the project has been drawn up, all the peculiarities of the soil have been taken into account and the corresponding construction materials have been purchased, you can start building the frame house yourself.

As for tools, these are:

- various levels;

- plumb;

- tape measure;

- level;

- screwdriver;

- hammers;

- Bulgarian;

- chainsaw;

- hand saw for trimming;

- lacing and others.

Foundation organization: nuances

Strip footing layout.

For this type of houses, the following types of foundations are suitable:

- strip,

- column-strip,

- monolithic.

To lay a column-ribbon base, dig trenches. It is important to locate them along the perimeter of the entire future structure, as well as under the main elements. The standard size of the depth is 1.5 m, then with a distance of 2 m reinforced concrete pillars are laid taking into account the level of soil freezing (such a calculation should be present in the design of the house). Further in the pits organize the formwork, which is further fixed by the concrete mix. After the solution dries, the pillars are fastened together by means of a metal grillage.

The ribbon base is prepared in the same way as the column-ribbon, with the exception of reinforced concrete pillars. Instead of them, rods with a cross-section of 1 cm are used. Cement mortar intended for pouring is made in the following proportion: cement (M400) with sand 1: 3. Well this kind of reason to use, if the house is planned basement.

The monolithic base under the frame house is built of reinforced concrete slabs. In this embodiment, it is necessary to provide a sand or rubble pillow into which the reinforced rods are inserted, then they are poured with a thin layer of cement mortar. After the implementation of such works, the formwork is performed, then the platform is thoroughly poured with concrete mixture. The average height of the platform should be 0.6 m, half of which should be occupied by a sand cushion. But each idea can have its own nuances.

Frame construction: recommendations

Floor plan of the frame house.

As already mentioned, it is the frame-frame method that allows you to implement almost any architectural idea. It is very good when there are a lot of windows so that the dwelling is lighter.Conveniently, the optional frame house is made in the form of a square or a rectangle, it can be round.

As regards the fastening of the timber, regardless of the shape of the house chosen, the connection of the parts will be the same. Since the frame consists of bars, it is very important to fasten them together correctly. Experts believe that the thorn-groove mount is the most reliable. For more reliable fixation of joints and joints steel plates, holders, connectors, angles of various sizes are used. Due to them, a higher level of rigidity is achieved. Fastening can be done with nails, bolts or anchors. Each type of fasteners used is determined by the appointment of fastening pillers.

It is necessary to start the frame only after the installation of the floor beams is completed. Vertical posts (40x140 mm bar, and if partitions are built, not load-bearing walls, 40x100 mm bar) can be used under the facade and internal walls. The installation step is 0.5 m. A beam intended for floor beams must be at least 0.5 cm thick, but the length must be chosen for the length of the spans.

It is best, of course, to purchase a bar of factory production, as it is guaranteed to ensure the accuracy of all joints and connections, rather than a bar prepared with his own hands. This moment is very important, as the strength and durability of the house frame directly depend on it.

Construction of the roof of the frame house

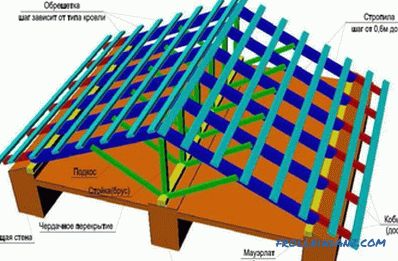

Scheme of the roof of the frame house.

Even at the design stage of a frame house, it is necessary to decide on the wishes of the number of ramps on the roof and their technical parameters. Since the work is done by hand, it is better to dwell on the variant of a gable roof. Here you should consider whether there is a loft in the house. In the case when the attic is planned to be insulated, the rafters are fastened in such a way that the step is equal to the width of the insulation. If you plan to organize a regular roof, then wooden bars with a diameter of 150x50 or 150x70 mm are suitable for rafters.

To ensure the stability of the rafters, they cut into the power plate due to the cut triangle (it is necessary that all sides separately be equal to 1/3 of the thickness of the rafter). The bolt serves as a thrust between the ceiling beams, which is mounted at the height of the ceiling. To do this, suitable timber size 50x150 mm.

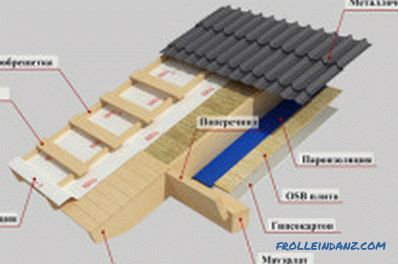

Next, the material is laid on the principle of a pie in this order: 1 - vapor barrier, 2 - counter grille, 3 - crate, 4 - waterproofing, 5 - roofing option.

The counter grille is designed to provide ventilation between the rafters and the crate itself. To do this, you can take the slats (thickness 0.2 cm), which are attached to the supports. For the crate frame, bars of 40x50 mm are taken, after which the roofing material is attached to it, depending on which the step of the bars will be selected. A waterproofing material is laid on this structure, and only then a roofing material.

Organization of insulation: features

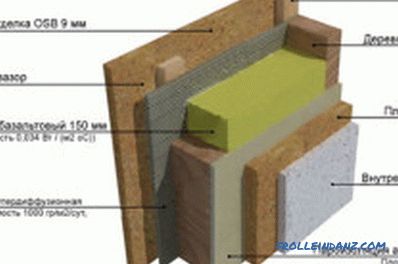

Scheme of the structure of the wall of a frame house with insulation.

It is very important that the insulation materials do not interfere with the ventilation of the frame house and provide good sound and heat insulation. Experts say that for high-quality insulation, its density should be at least 80 kg / m³. To do this, you can use polystyrene foam or mineral plates. But you should know that the second material can be of high quality only if it is the plates, not the mattresses. Space for insulation - between the racks of the frame. At fastening of expanded polystyrene also assembly foam is applied. And if mineral wool is used, a layer of 10 cm is laid in 2 times, that is, 2 layers of 5 cm.

Direct covering of walls

To cover the facade walls of frame houses take siding, facade slab, block house, plaster or painting.

At this stage it is necessary first of all to make the calculation of the dew point displacement, so that there will be no further shift towards the rooms. In the opposite case, in the winter time condensation may form on the walls, which adversely affects the wood. Inside the building is sheathed with clapboard, drywall or OSB. There is the possibility of plaster, wallpapering or painting. Each method is chosen individually, as it requires certain skills and financial costs.

If everything is done correctly, slowly, the result of the built frame house with your own hands will please for many years. Many neighbors will envy such a special and unusual dwelling.