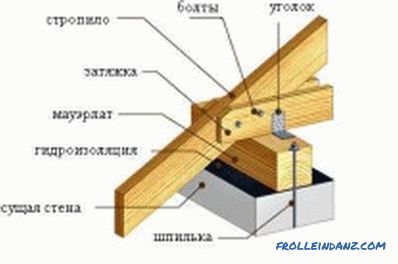

Mauerlat is one of the main elements of the roof structure. It is attached to the rafters. The operational period of the entire roof depends on the quality creation of the truss structure.

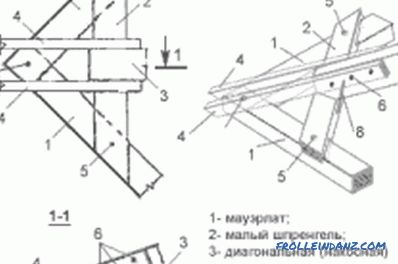

Rotor support nodes for the girder and power plate.

Basic methods for supporting the rafters

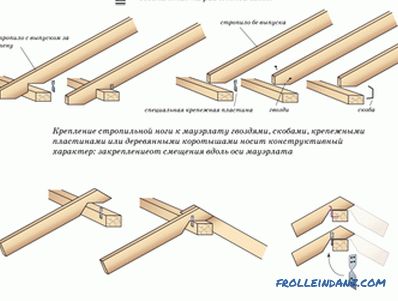

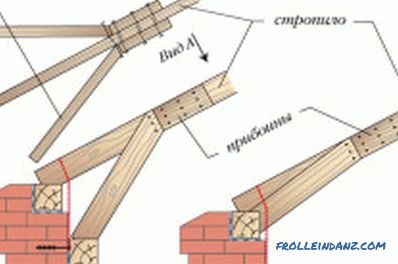

There are several technologies for supporting the rafters on a power plate. You can make a rigid fixation of the structure. She does not allow any displacement of the rafter foot. To do this, use a hemming bar, which prevents the rafters from slipping off at the place of bearing, and metal corners, which eliminate any lateral movement of the structure.

A rafter girder is used in wooden houses. Moreover, the main element for its emphasis is the upper crown, not the mauerlat. To prevent damage to the roof, the node supporting the rafters is made as free as possible. To do this, use a sliding support, which, when the log house shrinks, is displaced along the guide fixed on the leg.

A sliding support unit can be made using another technology. In the rafters done gash, which should adjoin the upper crown of the log house. For fixing beams, it is permissible to use any fasteners: brackets, nails or steel plates.

Fasteners for installation work

Support mounting unit on the diagonal truss foot.

In order to qualitatively connect the trusses with the power plate, you will need materials and tools such as:

- dry timber;

- boards;

- ax;

- hacksaw;

- hammer;

- knife;

- tape measure;

- plumb;

- level;

- screwdriver;

- drill;

- Bulgarian.

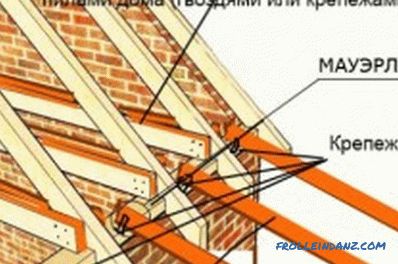

Particular attention should be paid to the presence of all fasteners. Fixing consoles of beams occurs with the help of beam brackets made of galvanized steel, which do not reduce the bearing capacity of the structure. Brackets in beams do not need to be embedded.

You need to buy a perforated mounting tape that will strengthen the power plate units. With its help, a strong connection of all elements of the structure is made. The tape also does not hit the beams. For its reliable fixation nails and screws are used.

In addition to the brackets and perforated tape, to ensure reliable support of the rafters to the mauerlat, you should purchase:

Wiring for nylon rafters.

- universal bar connectors;

- fasteners for rafters;

- embedded supports;

- wire rod;

- steel corners;

- rack fasteners;

- self-tapping screws;

- nails;

- brackets;

- plates;

- galvanized nails;

- studs with washers and nuts;

- anchor bolts.

Creating the ridge and installing the lower part of the rafters

Installation work begins with the ridge of the roof structure. The installation of rafters can be done in one of three ways:

- butt;

- per run;

- overlapped.

A butt joint design involves cutting the top of a rafter foot. This is done at an angle that equals the slope of the roof slope. A pair of legs join together on the skate. To get the same node bearing elements of the Mauerlat should use a ready-made template.

A special feature of fixing rafters on the girder is the presence of a ridge beam. Such a variant of the arrangement of the Mauerlat is characterized by increased reliability. But often such a system of supporting rafters provides for the installation of additional supporting structures, which will lead to a decrease in the functionality of the attic. Naturally, this method is not suitable for small roofs.

Support the wall rafters against the wall with armored belt.

The installation technology of overlapping rafters is in many ways similar to their installation on a ridge girder. The main difference - the connection of the upper legs overlap. This leads to a solid connection of the structure, because the studs hold two elements at once.

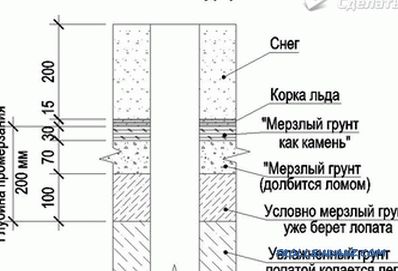

The connection of the lower ends of the rafters is carried out depending on the walling material. In the presence of wooden house-building, the top cladding of the wall can act as a supporting element. If the construction of the house used foam blocks (or aerated concrete), then the support of the rafters is made on the power plate.

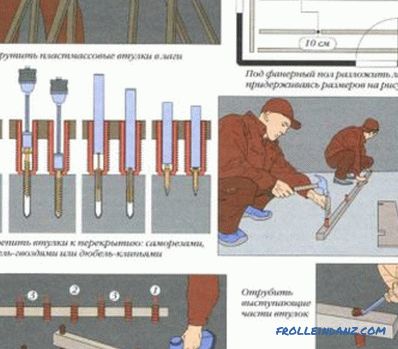

The device of the reinforced concrete belt is the optimal solution in the case of masonry building materials. This technology does not provide for the creation of any methods of fixing the truss system. Vertically located anchor bolts act as fasteners for timber. The main thing is that when pouring the concrete solution, the studs should be located in a strictly vertical position.

Connection of rafters with beams and power plate

After fixing the top and bottom of the rafters, fasten them to the beams.It is clear that you can connect the rafters with a beam just nails. But this is not the best solution. This mount will not be as reliable as possible. To prevent all elements from sliding, the truss structure is fixed to the beams by using spike and tooth connections.

If there is a steep slope of the roof (more than 35º), the cutting technology with a single tooth is used. At the bottom of the rafter is a tooth with a spike. Nests created in the beam should have a depth of 30% of the beam thickness. The device of roof connections is carried out at a distance of 0.3-0.4 m from the extreme part of the beam. This prevents the splitting of beams, resulting from a heavy load from the pressure of the legs.

The scheme for strengthening the rafters with additional struts.

When arranging the roof with an inclination of up to 35º, the installation of the rafters is carried out by expanding the interface area of the main structural elements. Usually the rafter leg overlap beam. To this end, holes for two teeth are cut in the truss leg:

- a thorn with a stop;

- another stop.

The depth of the cut when fixing rafters to the beam is within 30% of the beam thickness.

Better connections can be obtained by using bolts or clamps. This technology involves the use of wire loops, which are used to fix the node to the anchor bolts in the wall of the building.

Bearing on the mauerlat is the most common way of fixing the bottom of the rafters. A truss leg is cut to a size so that it can easily be put on the mauerlat. Otherwise, during the operation of the roof, a displacement of the bar may occur.

In some cases, the mauerlat must be "equipped" with a reverse notch. It depends on the type of wood from which the timber is made. If hardwood was used for its production, a slot is made, which, in combination with rafters, will create a locking element. In the manufacture of timber from coniferous wood, a cut is not required, as it will lead to a weakening of the structure.

The most acceptable option for a power plate is a tight pairing of the truss system.

Technology for mounting a truss system to a power plate.

This technology can be performed in one of two ways:

- using sawn bars and angles made of metal;

- by arranging saddles on rafters .

The first option is that a support bar is used to place the rafters on the mauerlat. Produced hard bearing truss legs. Reliable fixing of a design is carried out by metal corners. This prevents lateral movement of the structure.

The second option is more popular. Nails are used for fasteners, which are directed towards each other and driven at an angle. Two hammered nails intersect. After that, another nail is driven in. The third nail should be upright. Made the attachment point will be characterized by maximum rigidity, if you make an additional mount using wire-rod.

Didn't find the answer in the article? More information on the topic:

-

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building in case of serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.

-

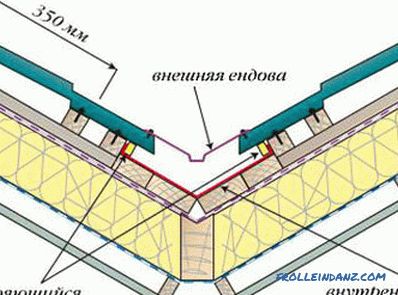

Features of the truss system

Truss Endova system: device features, necessary materials and tools. Varieties rafters installation diagram. Step by step installation instructions do-it-yourself.

-

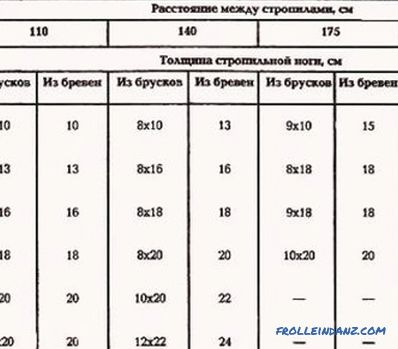

We make rafters for a two-slope roof

We make rafters for the roof with our own hands. Roof types and features of their construction. Materials required for arranging truss construction. The definition of the cross section of a bar or board.