Today, the construction of houses from a carriage, which is a two-sided timber, is becoming popular: ideally processed pine logs with a diameter of 330-350 mm, from which walls and internal partitions are made. The finished material is chopped logs from 300 to 500 mm in diameter, they are ground on two opposite sides up to 180-280 mm. The houses from the carriage are warm, functional, have an attractive appearance, do not require additional finishing with clapboard, siding and other decorative materials. New-fashioned houses are made using Norwegian technology, which is based on a special Norwegian house. Let us consider in more detail what the carriage, the Norwegian logging and the peculiarities of its implementation are.

The house from the mast is warm, functional, beautiful, does not require clapboard or other decorative materials.

Technology and features of cutting in Norwegian

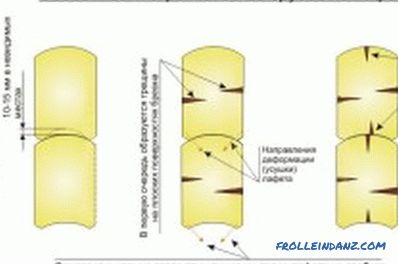

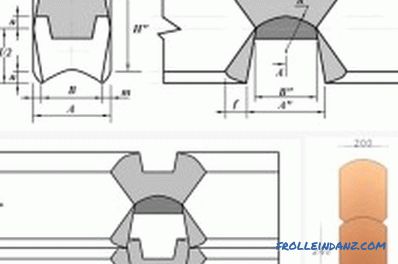

The technology of the Norwegian cutting implies preparation of a carriage for a log house and its installation. Log house is the basis of chopped houses. The log house consists of logs that are stacked on top of each other horizontally, forming crowns. The length of the logs is from 6 m. For a good fit of the elements forming the wall, a groove is made on the top of the log, where the inter-heater insulation is placed. At the corners of the logs are connected with special cuts, called locks. Locks have a wedge-shaped profile. Log building erected from wood, which has a natural moisture content. According to the Norwegian technology, the drying of the material occurs in a wooden house. After construction, the frame is dried, kept for a certain period, and then disassembled. Logs are laid with a combination of unsurpassed Norwegian locks, which, when the carriage house shrinks, self-glue under the force of its mass. When self-gluing the carriage can not turn. The density of the lock depends on the shrinkage: the larger it is, the stronger the lock turns out. He is the most reliable in Norwegian housing.

Scheme of carriages log cabins.

When erecting houses with a Norwegian castle, the material is monitored for damage, the selection is based on technical conditions and standards. The sawn lumber is cleared of bark, the trunks are processed with an eco-friendly antiseptic based on resins and turpentine; all kinds of growths, protrusions, defects are removed. Then the material enters the construction site, where the felling begins.

The structure is cut to size. After completion of the logging process, all logs are marked according to the assembly drawings. The frame is dismantled, the material is loaded on the transport and delivered to the assembly site, installed on the foundation. At installation, naglirovanie, installation of special pins (dowels, wooden nails of hardwood), which are installed (placed) inside the bars. Nagel prevent the movement of extreme elements in the process of drying wood, while maintaining the vertical arrangement of wood walls. Then the installation of the roof, windows and doors, painting of the house, engineering works, finishing, landscaping of the adjacent territories are carried out.

Distinguishing features of houses from a lafeta

When making a lafeta and erecting monitors of a monastery are used:

Logging.

- band sawmill with electronic and hydraulic systems;

- compasses with built-in levels;

- hammer drill;

- chainsaw;

- Norwegian axes of a specific shape;

- planer;

- machine;

- Tesla;

- truck crane;

- trucks;

- lifting equipment;

- transportation.

Modern power-saw benches have the ability to work with materials up to 11 m long, which is very important when building houses with long walls. The flat and smooth surface of the material allows you to save on finishing, as the carriage processed to perfect condition does not need a covering.

Type of connection of logs in the "Norwegian castle"

When considering in detail what a carriage is, one cannot help but touch it advantages and disadvantages. The use of the gun carriage as a building material in the construction of houses has many advantages. The walls inside and outside the building are flat. After grinding, they get a smooth surface, do not need additional finishing. The walls make it possible without much difficulty to conduct wiring from wires, cables and pipes. The useful area of the house is increasing, furniture, wall and wall cabinets and other structures, decorative elements perfectly fit into the interior, while the wooden frame makes it possible to maximize the use of the internal area. Thanks to the use of the Norwegian castle, the carriage houses are strong, durable, warm.

Wood is made from pine and larch, which are resistant to decay. Moisture is prevented from entering inside the log house. The advantage of a wooden house is the simplicity of the construction of unscheduled window and door openings, a healthy internal microclimate due to the use of environmentally friendly materials, low humidity and good ventilation. The thickness of the walls of the carriage reaches 200 mm, does not need insulation, the walls are characterized by good sound and heat insulation, the connection "Norwegian lock" ensures the reliability and rigidity of the structure. The disadvantages of the houses from the carriage include the removal when processing the upper layer of wood, which is the strongest, the material has cracks and gaps in the structure of the tree on narrow surfaces, the duration of the subsidence of the timber to set the strength of the structure.

The use of a carriage in construction allows the construction of a beautiful, reliable, practical, warm house with a wonderful indoor climate.

Didn't find the answer in the article? More information on the topic:

-

Features of sorting lumber

Sorting lumber is the process of selecting a board according to its properties. The presence of flaws and their number determines the grade of lumber.

-

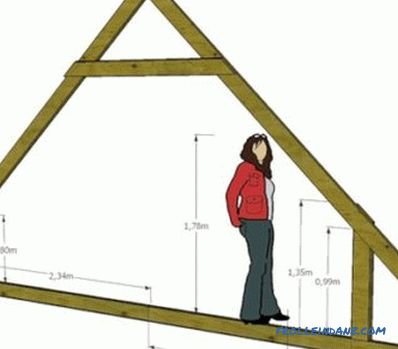

Types and features of truss

Roof roof structures: types, features of their installation. The elements that make up truss systems, their role in the overall design. The advantages of roof systems.