OSB act as one of the relatively new materials used in construction and finishing works, moreover, OSB has recently become increasingly popular among builders and private developers. Stacked OSB on a wooden floor, as well as on concrete bases. The material is characterized by lightness and increased strength, compared with analogues, their structure is able to perfectly undergo the effects of moisture. Installing the OSB is easy, and the cost of these products is very low.

OSB is a moisture resistant material, which indicates its high strength.

Installation Features

It is preferable to use OSB-3 boards for flooring, since they are characterized by high density and moisture resistance.

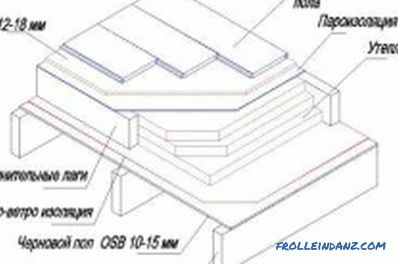

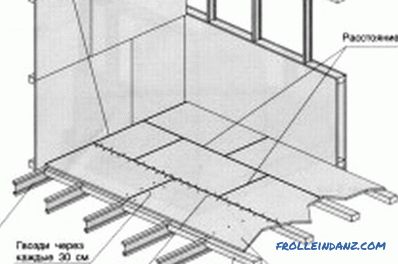

Figure 1. Floor installation with the use of OSB slabs.

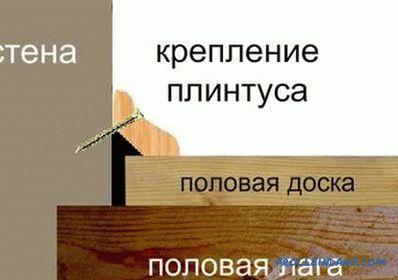

If the floor is leveled with OSB on the surface of a concrete screed, then a material whose thickness does not exceed 10 mm should be used, but if the plates are mounted on the base of wooden lags, then more massive products should be used, the thickness of which will determine the step between the fortified lags. The material for laying on the logs should have a thickness of 15-18 mm, if the distance between them does not exceed 0.5 meters. But if the step between the lags is higher than 60 cm, then the plates should have a thickness in the range of 22-25 mm. In fig. 1 you can see how the floor should be arranged using OSB slabs.

The standard dimensions of products called RSD are 2440x1220 mm. The plates are easy to cut, for this you should use a circular saw, but it is better to refuse to use a jigsaw in the process, since it does not allow to get a straight line of cutting, which is especially important for the further installation of linoleum.

Tools and materials

- glassine;

- circular saw;

- glue;

- OSB;

- dowels;

- self-tapping screws;

- level;

- pencil;

- nails.

Leveling the concrete floor with OSB

Leveling the concrete floor with the RSD.

Leveling the floor OSB provides an excellent basis for laying various finishing coatings, among them: linoleum, ceramics, laminate, parquet. In addition to alignment, these products are able to provide sound insulation, which becomes possible due to the multi-layer dense structure of the material. Plates OSB warm and well waterproof the floor. If there is a concrete screed as the subfloor, the last wooden bars that act as genital lags are laid, and wooden lags help to smooth out the errors of the concrete base.

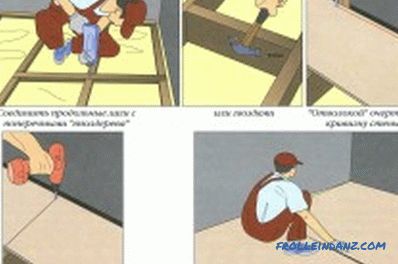

In order to obtain the proper rigidity of the floor and its resistance to deformation, it is preferable to cover the surface of the OSB with plates laid in 2 layers.

At the same time, each plate should have a small thickness - in the range of 8-10 mm. In the second row, the slab should be laid on the OSB floor with some displacement so that the seams between the rows do not coincide. The layers of material should be fixed using special glue, which can be replaced with fasteners in the form of spiral or ring nails.

It is possible to cover the concrete surface of the OSB with a slab without first preparing it in the form of laying wooden lags. In order for this technology to have the right to life, the concrete screed should first be checked for horizontal position, using the long rule. If it does not have errors, then you can proceed to leveling the OSB floor immediately. In this case, the floor can be leveled using a single layer of material, reinforcing the products with dowels and screws.

Expansion joints.

The surface leveling using OSB plates should be carried out taking into account the arrangement of compensation temperature joints, this is necessary because the products are able to deform during operation, absorbing moisture into the thickness of the wood elements, and then returning it. Such gaps should be made between the plates, and their width should be approximately equal to 3 mm.

If the floor is leveled using floating technology, then during installation it will be necessary to ensure that the distance from the walls to the flooring is 10-15 mm. Floating floors during the installation of the material does not imply the implementation of rigid screed plates and walls, as well as the base.

Leveling a wooden floor with OSB

In the rooms of houses that were built on a filler or columnar base, the floors are usually laid on wooden logs made of a multi-layered board or timber. To level the floor and in this case it is possible OSB plates, which are used not only as a draft, but also as a finished floor.

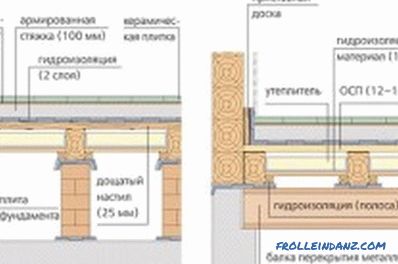

The wooden floor on the basis of the lag should be tested for strength before attaching the products to it.The rough floor of the OSB on the logs settles on the underside of the lag, while the surface that faces the soil must necessarily be treated with a protective coating, which can be, for example, bitumen mastic. In the space, which was formed by lags and a rough base, a heat insulator is mounted, the latter is protected from above by a protective material, for example, glass asphalt. Then you can begin to mount the base for the finished floor.

Figure 2. Leveling the wooden floor using the RSD.

OSB panels, which constitute the basis for the finished floor, are mounted in one or two layers, the latter option involves laying the material perpendicular to each other. The first layer should be mounted with a joint on the logs on the smaller side. Layers between themselves can be strengthened by means of spiral nails, and to ensure greater strength of the surface of the OSB floor, the plates are additionally attached with glue. Connect the plates and logs can be self-tapping screws, strengthening them at a distance of 25-30 cm from each other. In fig. 2 you can see how the OSB floor is leveling with boards; these recommendations will help with the independent implementation of work.

It is also necessary to mount the slabs on a wooden floor, providing so-called dilatation gaps, which is done in the case of concrete foundations.

Once the floor leveling is completed with OSB, you should decide whether to use such a base as a surface for laying the topcoat or leave OSB as a front floor finish, which is also often practiced. The strength and evenness of such a foundation allows you to immediately proceed to further finishing work floor, but this floor can be left unchanged. The slab will only need to be protected from mechanical wear, for which it is recommended to use varnish, which must be applied in several layers on the surface. Before the start of painting such wooden floor should be cleared of debris and dust by wet cleaning, and then dried.

If it is intended to lay linoleum or carpet on the floor after leveling, then it will be necessary to ensure as smooth a transition as possible in the place where the joints will be formed, this applies to all rolled materials. To do this, it is preferable to use plates that have the minimum allowable thickness. After it was possible to level the OSB floor, the gaps formed will need to be processed using an elastic sealant.

Laying ceramic tiles on the RSD.

If, after leveling the OSB floor, it is intended to lay ceramic tiles, it will be necessary to ensure complete immobility and perfect foundation reliability. For this, it is permissible to use a more frequent arrangement of the lag, on which the slabs must be reinforced as carefully as possible and with the greatest number of fasteners. The best solution would be to use when installing the plates, which are equipped with a fastener of the "thorn-groove" type. When laying tiles, you should use a special glue that is designed to work with wood and ceramics.

Before leveling the floor with OSB, you need to become familiar with the technology, otherwise you will have to redo the work, for example, because of uneven ground unevenness. Thus, the surface of the lag can be leveled using the planing method, and the concrete floor can be leveled by the method of laying wooden chocks. This is true with minor irregularities, as correction with concrete may not give the expected results.

The use of OSB slabs guarantees quick and high-quality leveling of surfaces in any room. For the work does not require special skills and tools. If the laying of the plates is done on the logs, then the step between the latter should be equal to 56 cm, which is excellent for installing all modern types of heat insulator. If you want to save, the use of OSB plates for leveling will be an excellent solution, because they not only have a democratic cost, but can also be used without additional finishing.

Didn't find the answer in the article? More information on the topic: