Many car owners would like to build a garage. And this is not surprising, because if you leave your transport under a canopy or just in the yard, it will not be protected from weather conditions or bullies who can damage it or in the worst case steal it. This is a guarantee that your "iron horse" will be safe and sound. Moreover, in the garage you can carry out repairs and maintenance of the car, so the building itself should be spacious, well equipped, comfortable and, if necessary, warm to protect you and the car from bad weather. If you purchased a house without a garage, or if you did not build it at home, you can fix it by building it yourself. Most often, brick is used for construction, which is popular for its fire safety, durability and resistance to biodegradation. If you are the owner of a car that wants to make him a "house", from this article you can learn how to build a garage out of a brick with your own hands .

Types of garages

Before you start building your garage, you need to decide on its type. How many cars there will be - one or two. All designs are divided into types. It depends on where and how they are placed. Below are three types of garages:

- attached to the house;

- built into the house;

- separate building.

The garage is attached to the house

The garage is attached to the house

The garages attached to the dwelling are very comfortable, since it is possible to enter them not only from the front, but also from the side, immediately from the house. They are heated with the house, as they have a common power supply and water supply system.

Garage in the house

Garage in the house

The garage built into the house is made at the initial stage of building the house. But in such a garage there are advantages: it is convenient, because you can get into it right away from home, and for this design does not require additional laying of communications.

A detached garage

A detached garage

A single building is the most common option in our area. This garage should be built as a separate building with its own communications: heating, electrical network and water supply (if needed). It is better to place such buildings near the place of exit from the yard. The best option is to build a garage in a line with a fence, at the level of the plot, so that the gates open directly onto the street.

Since basically a separate building is chosen, let's consider how to build such a garage on our own in several stages.

The first stage of construction is the garage project

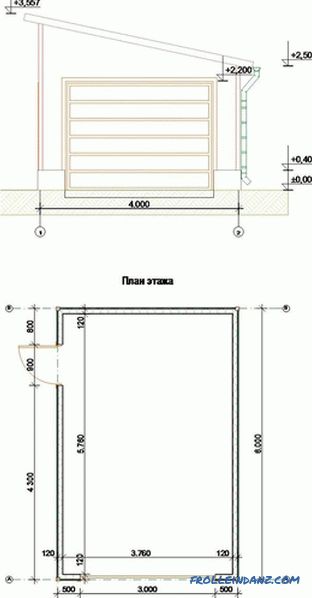

Garage plan

Garage plan

Any construction, Be it a house, a bathhouse or a garage, it starts with planning. A project is not always a huge roll of paper with detailed drawings. You must see and imagine what you need to build and how. Therefore, you can even take a regular sheet from a notebook and pre-draw a future building so that you can continue to navigate to something.

The first thing to consider when designing is the tasks that the building should solve. Will it be used only as a car park, or will you inspect the car and carry out repairs? Do I need a cellar or an inspection pit? Will the attic be made? All this must be taken into account and transferred to paper.

The second point is the size of the future construction. Again, the dimensions should be chosen based on the area where the garage will be built, as well as depending on the tasks for which it is needed. Suppose you only need to store your car. Then the size of the garage 3 * 5.5 m will be just right (of course, if you do not have a truck). If you plan to make a viewing pit, cellar or install additional equipment, then the dimensions will be different.

The second stage of construction - the marking of the area

The marking of the area

The marking of the area

After a drawing of the future garage was made; all this needs to be moved to the place of construction. For this you will need:

- A long rope or a nylon cord, 30-40 m.

- A dozen pegs measuring approximately 40 cm.

- A hammer or a sledgehammer.

- Roulette for at least 5 m.

Having prepared all the tools, you need to clear a place for construction. Focusing on the drawings, drive pegs at the corners of the future building, adhering to the specified dimensions. Connect them with a rope or cord. Thus, you have prepared the base , for the next phase of the garage construction, which will serve as a guide.

The third stage of construction - excavation

Digging of the trench

Digging of the trench

So, proceeding from the markings on the soil, it is necessary to dig a trench to fill the foundation. This can be done manually by yourself or with a friend with a shovel. If a cellar or pit is provided for in the project, it will be rather difficult to do this without an excavator.

An ordinary strip foundation will be suitable for a garage. Its width must be at least 40 cm.And depending on the depth to which the soil freezes through, the depth of the foundation can vary from 60 cm to 120 cm. The average depth optimal for a garage is 100 cm. Based on these dimensions, you should dig a trench. Make sure the walls are vertical and even. The bottom should not be loose. To improve the quality of the foundation, at the bottom you can make a five-centimetric cushion of rubble or sand, tamping it down.

The fourth stage of construction - foundation filling

Filling the foundation of the garage

Filling the foundation of the garage

Simple and An inexpensive type of foundation that can be used is a butobeton foundation. It is quite simple to make it: a rubble stone is placed in a prepared trench, and each row is poured with cement mortar until the trench is completely filled. It is known that the stronger the foundation, the longer will be the construction. It also determines the degree of shrinkage of the building and the likelihood of cracks. That is why for the solution you need to choose high-quality materials.

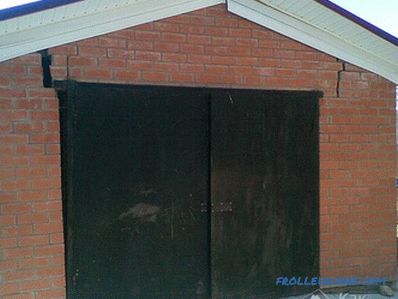

The gate for the garage can be made by yourself. Most often they are placed on a foundation, and then they are laid with bricks. If the garage is heated, the gate must be insulated.

To make the mortar, you need high-grade cement, sand, plasticizer and water. The solution should be kneaded in a concrete mixer. For 1 bucket of cement you need 2.5 buckets of sand. Water is added to obtain the desired consistency.

The rubble foundation

The rubble foundation

You can use the usual for pouring the foundation solution with rubble without using rubble stones. In this case, the solution will need more, and in the trench, you should install a reinforced mesh.

If the ground is solid, formwork is needed only in the ground part to make the base. It can be made of boards, exposing all of the level. To prevent cement flow, do not allow gaps and holes in the formwork. Also, it should be strengthened with braces. Foundation filling should be done in several layers, and not partially in some areas. After pouring out of it, you need to expel the air and tamp, and at the end level with a trowel. Cement will dry in a week, but you should start laying walls no sooner than in a month.

Now it is necessary to protect the base from the ingress of water by engaging in waterproofing works. To do this, lay 1-2 layers of roofing material on the base. You can also cover it with bitumen. Due to this, the walls will not absorb moisture from the ground, and the base will not collapse.

Fifth stage of construction - laying of walls

Laying walls

Laying walls

As soon as the foundation completely dry, you can proceed to the construction of brick walls. They can be made in 1 brick in areas with a warm climate, and in 1.5 bricks where it is cold to warm the garage. When working it is important to follow three rules:

- Avoid imbalances. Laying should be perfectly flat.

- Choose a brickwork scheme and stick to it until the very end.

- Knead the solution correctly. It must be the same throughout the laying. If you choose the ideal proportion - 3 to 1 (sand, cement), then the solution should be such constantly.

- Watch the seam thickness, which should be the same, not more than 1 cm. You can use the sample in the form of a 8 mm lath when you expose each brick.

To work, you will need:

- construction level;

- plumb;

- lace or fishing line;

- trowel;

- bricks;

- pick;

- large capacity for mixing mortar;

- buckets;

- shovel.

Chain masonry

Chain masonry

As always, you need to build walls with chain masonry so that one row overlapped the seams of another row. It is necessary to begin laying bricks from the corners. First, lay the corners of the brick so that everything is perfectly smooth, use the construction level. Then pull the cord or line between the corners so that it is flush with the top of the brick. It is important that the rope does not sag and be evenly stretched.

Now you can start laying. From the corners, place new bricks, pushing them to the level of the fishing line with the handle of a trowel or pick. After the rows around the perimeter are laid out, lift the corners, stretch the cord and continue working. Especially carefully monitor the corners. To check the verticality of the walls, use a plumb line and level.

If there are shelves in the garage, consider their location in advance.

If the roof is sloping, it is important to ensure adequate slope for the water flow. Given this, the end walls must be made of different heights, and the upper edge of the walls, which on the sides - with a slope. If your garage is 6 meters long, a slope of 30 cm will suffice. To do this, for every 1 meter you make a slope of 5 cm. In order to keep things straight, you can use a stretched cord.

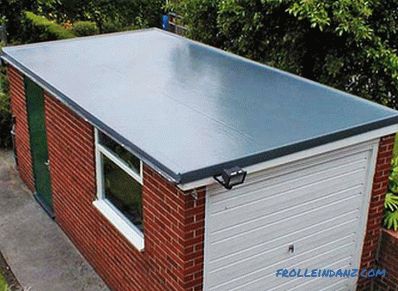

The sixth stage of construction - roofing

Shed single garage roof

Shed single garage roof

Shed single roof - simple and inexpensive. For its device you will need wooden beams with a section of 100-120 mm. Thanks to them, it is possible to ensure the overlap of the garage, 6 m long. The length of the beams is selected depending on the width of the garage, but they should be 20-25 cm longer. They should be laid across the garage, in 80 cm steps. Beams should follow the slope of the walls. You can fix them directly to the wall of the garage.

The ceiling must be insulated.

Then 40 mm thick boards are laid on the beams, shifting them as tightly as possible. After which they are nailed to the beams so that large gaps do not form. The next step is waterproofing. The layer of roofing material is placed from bottom to top over the boards so as to form the overlap of the lower layer of a few centimeters. Thus, the water will not fall on the boards, and freely be able to slide down. Roofing material is fixed with nails.

After that, the roofing material is laid on the wooden flooring. His choice is great:

- decking is resistant to precipitation, and relatively inexpensive;

- slate, time-tested material that is easy to install, and it serves for a long time and looks good;

- metal tile or tile, suitable for large and medium garages;

- folded roof, reliable and easy to install material from sheet metal.

Seventh stage of construction - floor shading

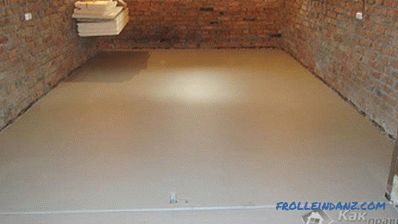

Concrete floor

Concrete floor

Concrete foundation and self-leveling floor - the main types of floor device in the garage. To make a concrete floor, you need to remove the top layer of soil and tamp the area with sand, a layer of 10 cm. In order for the water that flows into the garage to flow out of it, you need to withstand a slope of 2-3˚ to the gate. After tamping, lay a waterproofing material (roofing material is the best option) and make a concrete screed with a thickness of 10-15 cm.

The floor of the garage must withstand heavy loads and be strong enough. To increase the durability and strength of the base, the floor is additionally stalked with a reinforced mesh. The brand of concrete must also be high.

But concrete is not the only option to fill the floor. In some cases, make it out of wood, but more often resort to cement screed. To do this, the ground is filled with small and large gravel. Then it is well compacted and the cement mortar is poured in 2 stages. The first layer, which is 4-5 cm thick, needs to be poured immediately. A few days later pour the second layer, the thickness of which is 2-3 cm. It should be more liquid. After that, the floor is leveled and waits for drying.

Self-leveling floor

Self-leveling floor

Today, self-leveling floor mixes have become very popular. The second layer of fill can be made from this mixture. Ready floor paint at will.

Also in the garage you can make a self-leveling floor. The resulting durable coating does not require painting.

The filling floor in the garage room

The filling floor in the garage room

Outside, you need to make a blind area 50 cm. She done in the same way as the floor inside, only its thickness can be 4-5 cm, this is quite enough. Since the blind area serves to drain the liquid, it must be done on an incline.

A beautiful brick house with a garage

A beautiful brick house with a garage

The wiring must be completed before plastering.

That's all. Optionally, the garage can plaster and whitewash, or just wipe the walls with a solution of cement. Now the "house" for your vehicle is ready.

Video

This video will help you to properly lay the walls of the facing brick:

Photo

Installation of the metal door frame

Installation of the metal door frame

House with garage

House with garage

Brick garage with attic

Brick garage with attic

Garage from facing brick

Garage from facing brick

The flat roof of the garage

The flat roof of the garage

Brick garages in an auto cooperative

Brick garages in an auto cooperative

There is no good foundation for this garage

There is no good foundation for this garage