The wooden shelf on the farm is simply indispensable, but it can not only serve as a place to store dishes or books, but also become a real decoration of the interior. It is noteworthy that wooden shelves can be made by hand, for this there is no need to have special skills, you just need to strictly follow the recommendations of experts. If everything is done correctly, there is no doubt that the shelf, made by yourself, will look no worse than that acquired in the store.

A shelf on the farm is a very useful and necessary item for storing certain items. For its construction a great tree.

The following tools will be needed for this:

- Hacksaw.

- Tape measure.

- Grinding machine.

- Sandpaper.

- Screwdriver.

The process of making a wooden shelf

The simplest way to make a wooden shelf is a box-shaped shelf.

So how are the shelves made with your own hands?

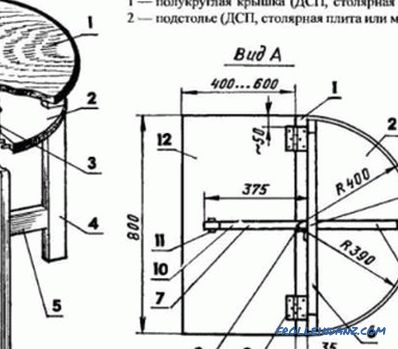

First of all, you need to figure out what shape the shelf of wood will be made. The easiest way to make an ordinary box of wood, which is hung on the wall. Such work does not require a lot of time and skills, but it is much more pleasant when there are wooden shelves in the house that are made outside the box. Such furniture always attracts attention. Particularly attractive is the fact that a sketch of such furniture can also be made to your liking.

After the issue with the design is resolved, you need to decide on the main dimensions. It is necessary to take into account what is planned to be placed on such shelves, and the size of the place where the shelf will be installed also matters. After that, you can begin to manufacture furniture, with regard to the material, it is strongly recommended to use laminated chipboard.

The cut edges must be perfectly flat, to achieve this, you need to work with a machine, and in this case, the manual circular saw will do. If the decision is made to use a manual circular saw, then you need to choose a disk with the smallest teeth, then there will be no chips on a wooden surface or they will be completely insignificant. If there is an opportunity, it is necessary to resort to the services of cutting material directly in the store, the acquired sliced material eliminates many troubles.

Now that the panels are ready, you can begin to process the edges with emery paper. If you can, it is better to use a grinding machine. The purpose of this treatment is to carefully get rid of the edge chipping, after which the surface must be leveled so that the end edge can be glued.

Some nuances of the workflow

At the edges of the shelf it is necessary to glue the edging.

The end edge and the heating element (as such it is quite possible to use an ordinary iron) is the next stage of making the shelf with your own hands. Kant should be gently attached to the end of the panel, then it is cut off, but you need to leave a small margin. Then you need to iron everything well with a heated iron several times, the piping should stick tightly. Now you need to wait until the butt is cool, and get rid of the excess with a clerical knife, but this should be done carefully. When the excess edge is cut, it is necessary to walk manually on the corners of the slab with emery paper. This should be done in order to get rid of the flaws that appear after cutting off the excess edge. Flaws can occur due to large chips.

We can assume that the shelf of wood is ready, you just need to fasten the panels together. Such parts can be fastened in a variety of ways, one of the best options is the use of confirmatte screws, and as for hats, they are hidden by special plugs. To fasten a wooden shelf with such screws, you should use a drill, the diameter of the drill can be 5, 6 and 10 mm.

The shelf is hung on the wall with canopies; they are easily screwed on top of the ends of the vertical panels.

Now the excellent home-made furniture is finally ready. It becomes clear that this does not require a large amount of time or a large amount of money. And all this is done without much difficulty.

Didn't find the answer in the article? More information on the topic:

-

How to make furniture yourself

How to make furniture yourself. What are the materials, and what is their difference? Variants of the drawings, as well as a description of the manufacture of an example. What else you need to know when deciding to do this kind of work?